1001TUTORIAL1001TUTORIAL

JENTIK : Jurnal Pendidikan Teknologi Informasi dan KomunikasiJENTIK : Jurnal Pendidikan Teknologi Informasi dan KomunikasiThe development of the food and beverage industry demands innovation in efficient and reliable packaging processes. Conventional cup sealing machines often face limitations in speed and precision, necessitating technology-based solutions. This study aims to design and implement an automated cup sealer system based on the Internet of Things (IoT), using the NodeMCU ESP32, capable of performing sealing and real-time monitoring. The system integrates a flowmeter sensor to detect the presence of cups, a stepper motor for the sealing process, and an LCD display along with WiFi connectivity for monitoring production data. The methodology involves hardware design, control system programming, and performance testing of the device under various temperature and motor speed parameters. The results show that the system can increase production efficiency by up to six times compared to the manual method, with a capacity of 300 cups per hour and a sealing success rate of 95% at an optimal temperature of 100°C and a motor speed of 10 RPM. Synchronization among components was enhanced through sensor calibration and algorithm development. In conclusion, this automated system not only improves efficiency and accuracy but also offers flexibility and IoT-based control, making it highly relevant for small and medium-sized industries.

In conclusion, this automated system improves efficiency and accuracy, offering flexibility and IoT-based control, making it relevant for small and medium-sized industries.The system successfully integrates a flowmeter sensor, stepper motor, and NodeMCU ESP32 for precise cup sealing and real-time monitoring.Challenges in sensor synchronization were overcome through calibration and algorithm development, resulting in a sixfold increase in production efficiency compared to manual methods.

Future research should focus on conducting field tests in real industrial settings to assess the systems durability and reliability under actual operating conditions. Expanding material compatibility by testing with various cup materials and dynamically adjusting sealing parameters would broaden the systems applicability. Furthermore, developing a mobile application for remote access and control, coupled with the integration of machine learning algorithms for automatic fault detection, would significantly enhance the systems overall performance and usability, paving the way for wider adoption in the manufacturing sector and contributing to the ongoing digital transformation of industries.

- Australian and New Zealand Laboratory Experience and Proposed Future Direction of Wastewater Pathogen... mdpi.com/2076-3298/12/4/114Australian and New Zealand Laboratory Experience and Proposed Future Direction of Wastewater Pathogen mdpi 2076 3298 12 4 114

- IoT-Based Cup Sealer Machine Automation Using Nodemcu ESP32 | JENTIK : Jurnal Pendidikan Teknologi Informasi... ejournal.1001tutorial.com/index.php/jentik/article/view/442IoT Based Cup Sealer Machine Automation Using Nodemcu ESP32 JENTIK Jurnal Pendidikan Teknologi Informasi ejournal 1001tutorial index php jentik article view 442

- The Influence of Firm Age on Profitability Performance of Indonesian Manufacturing Companies with The... doi.org/10.20961/jab.v22i2.844The Influence of Firm Age on Profitability Performance of Indonesian Manufacturing Companies with The doi 10 20961 jab v22i2 844

- Review of Monitoring and Control Systems Based on Internet of Things. review monitoring control systems... mdpi.com/2076-3417/14/19/8943Review of Monitoring and Control Systems Based on Internet of Things review monitoring control systems mdpi 2076 3417 14 19 8943

| File size | 407.21 KB |

| Pages | 8 |

| DMCA | Report |

Related /

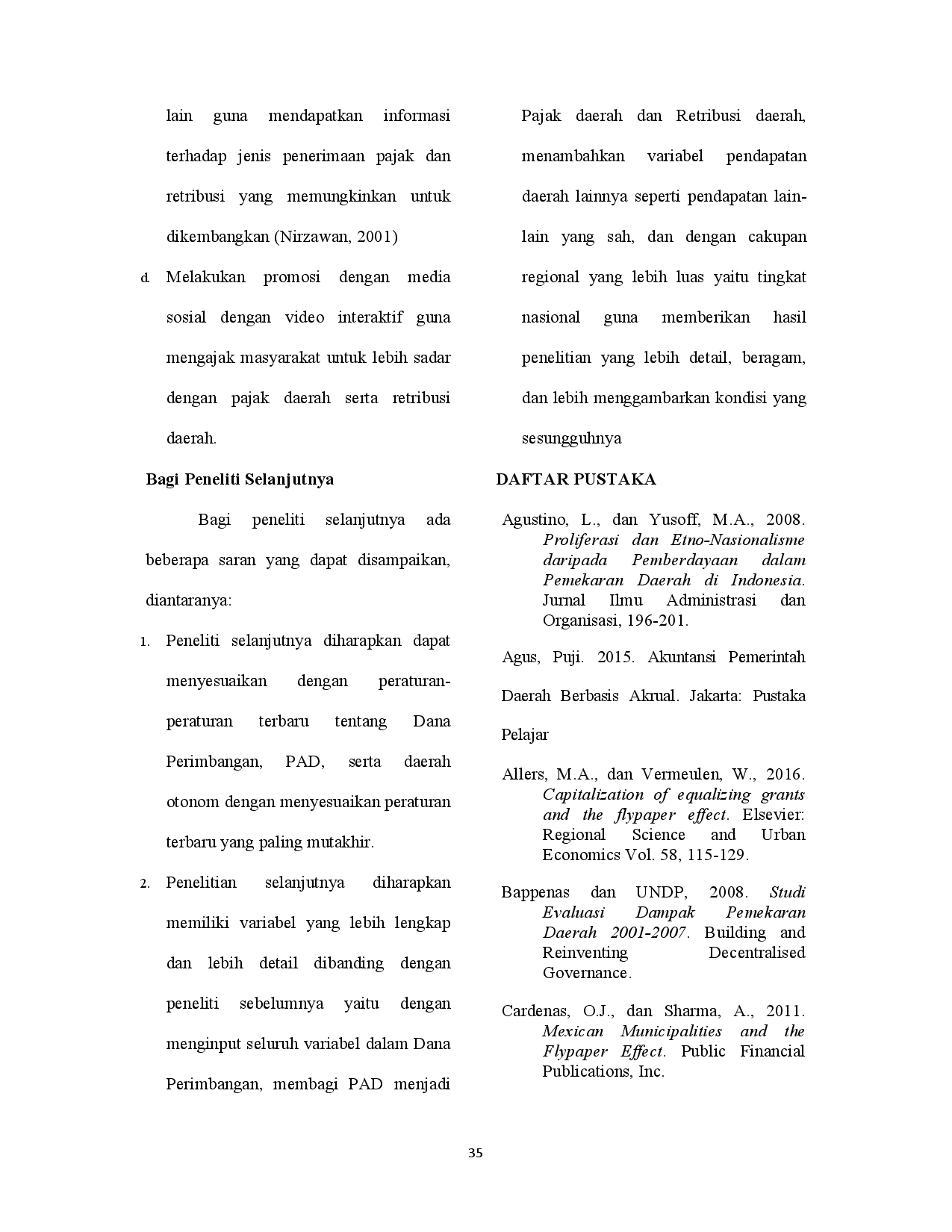

BPKBPK Penelitian ini bertujuan untuk menganalisis pengaruh Dana Perimbangan (DAU, DAK, dan DBH) serta Pendapatan Asli Daerah (PAD) terhadap Belanja Daerah PemerintahPenelitian ini bertujuan untuk menganalisis pengaruh Dana Perimbangan (DAU, DAK, dan DBH) serta Pendapatan Asli Daerah (PAD) terhadap Belanja Daerah Pemerintah

STAIM PROBOLINGGOSTAIM PROBOLINGGO Penelitian ini mempergunakan pendekatan kuantitatif melalui metode quasi eksperimen dan desain nonequivalent control group design. Sampel penelitian terdiriPenelitian ini mempergunakan pendekatan kuantitatif melalui metode quasi eksperimen dan desain nonequivalent control group design. Sampel penelitian terdiri

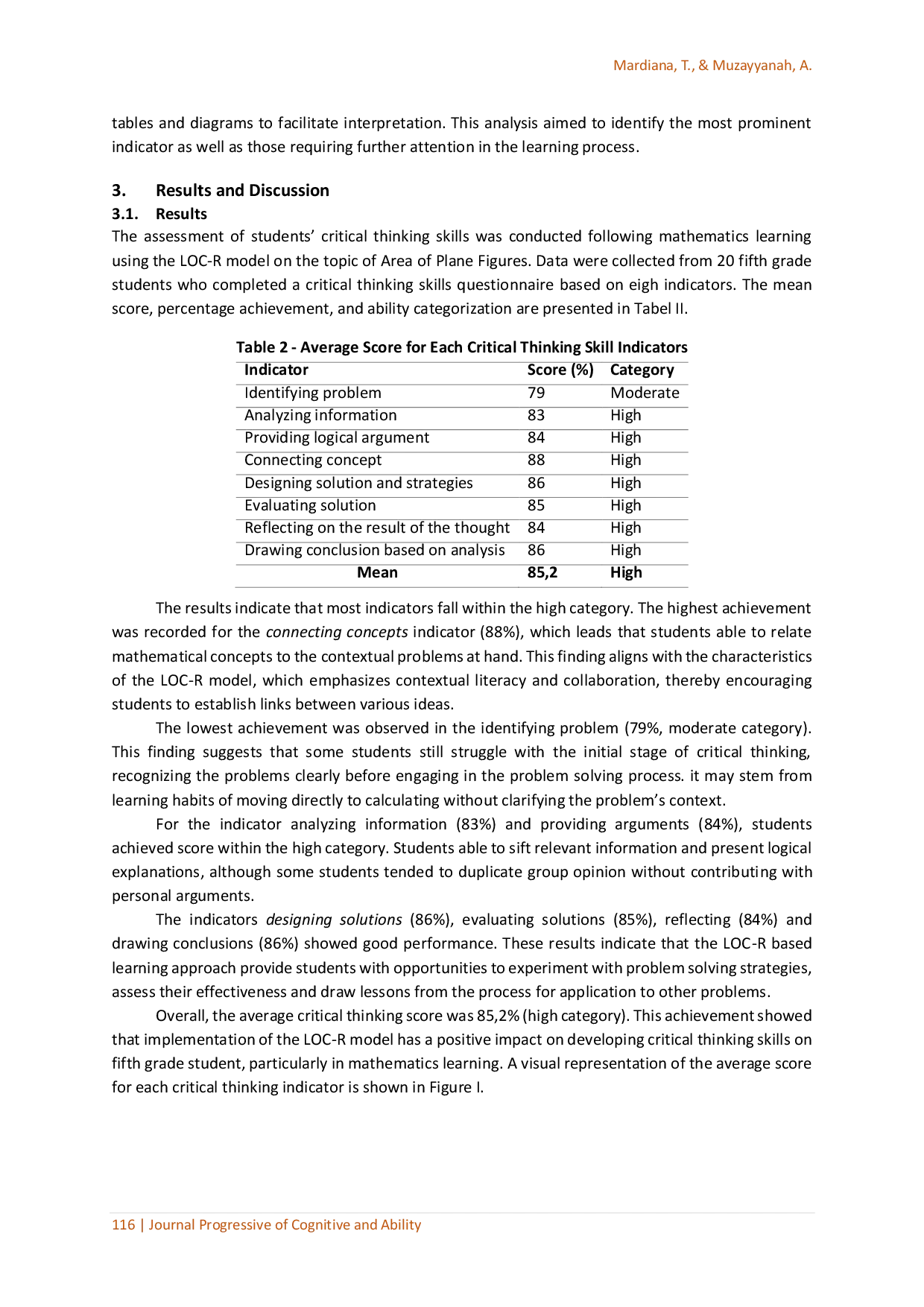

EDUPEDEDUPED Penelitian ini menegakkan bahwa model LOC-R efektif dalam meningkatkan keterampilan berpikir kritis siswa, menjadi strategi pengajaran matematika alternatifPenelitian ini menegakkan bahwa model LOC-R efektif dalam meningkatkan keterampilan berpikir kritis siswa, menjadi strategi pengajaran matematika alternatif

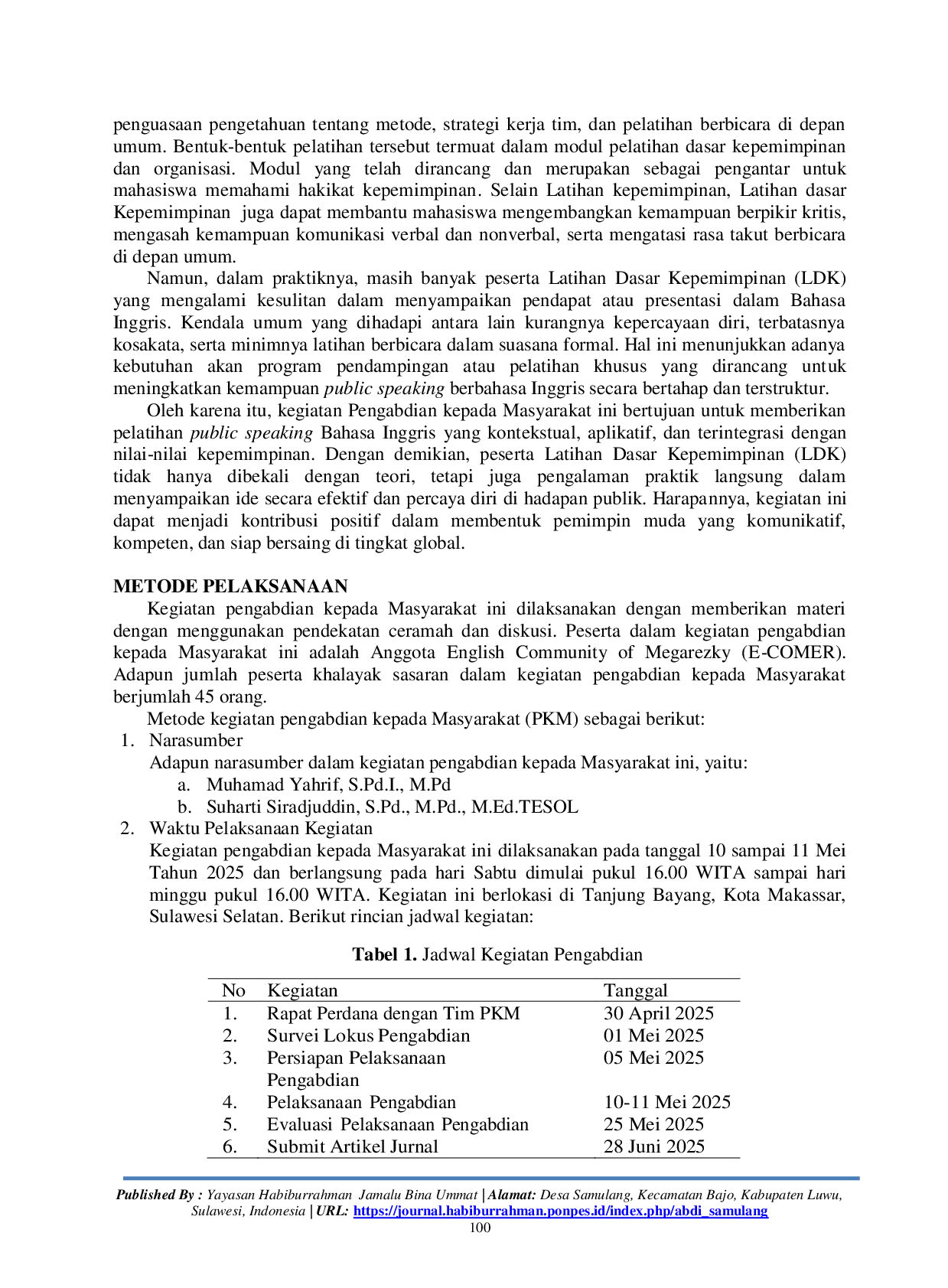

HABIBURRAHMANHABIBURRAHMAN Latihan Dasar Kepemimpinan (LDK) merupakan momen strategis untuk tidak hanya menanamkan nilai-nilai kepemimpinan, tetapi juga mengasah kemampuan komunikasiLatihan Dasar Kepemimpinan (LDK) merupakan momen strategis untuk tidak hanya menanamkan nilai-nilai kepemimpinan, tetapi juga mengasah kemampuan komunikasi

1001TUTORIAL1001TUTORIAL Studi ini bertujuan untuk mengkaji efek pandemi Covid-19 terhadap rutinitas akademik mahasiswa universitas dan mengidentifikasi tantangan yang muncul akibatStudi ini bertujuan untuk mengkaji efek pandemi Covid-19 terhadap rutinitas akademik mahasiswa universitas dan mengidentifikasi tantangan yang muncul akibat

STITMUBASTITMUBA Hasil uji paired sample t-test menunjukkan nilai t-hitung 12,47 dengan p-value < 0,001, yang menunjukkan peningkatan yang sangat signifikan. ObservasiHasil uji paired sample t-test menunjukkan nilai t-hitung 12,47 dengan p-value < 0,001, yang menunjukkan peningkatan yang sangat signifikan. Observasi

PENCERAHPENCERAH Penelitian ini menggunakan teori akuntabilitas Mardiasmo, yang terdiri dari 4 variabel: akuntabilitas hukum dan kejujuran, akuntabilitas proses, akuntabilitasPenelitian ini menggunakan teori akuntabilitas Mardiasmo, yang terdiri dari 4 variabel: akuntabilitas hukum dan kejujuran, akuntabilitas proses, akuntabilitas

RANDWICKRESEARCHRANDWICKRESEARCH Penulis mengeksplorasi penggunaan media digital untuk meningkatkan aksesibilitas dan interaktivitas materi. Hasilnya menunjukkan potensi peningkatan pemahamanPenulis mengeksplorasi penggunaan media digital untuk meningkatkan aksesibilitas dan interaktivitas materi. Hasilnya menunjukkan potensi peningkatan pemahaman

Useful /

STAIM PROBOLINGGOSTAIM PROBOLINGGO Namun demikian, penggunaan humor menuntut kepekaan etis dan kemampuan komunikasi guru yang baik. Oleh karena itu, disarankan adanya pelatihan bagi guruNamun demikian, penggunaan humor menuntut kepekaan etis dan kemampuan komunikasi guru yang baik. Oleh karena itu, disarankan adanya pelatihan bagi guru

UHAMKAUHAMKA Metode yang digunakan dalam penelitian ini adalah deskriptif kualitatif. Membaca kumpulan cerita pendek dengan seksama merupakan teknik pengumpulan dataMetode yang digunakan dalam penelitian ini adalah deskriptif kualitatif. Membaca kumpulan cerita pendek dengan seksama merupakan teknik pengumpulan data

STIFERASTIFERA Pengujian yang dilakukan antara lain: karakteristik fisik meliputi organoleptis, homogenitas, pH, viskositas, daya lekat, daya sebar dan indeks iritasiPengujian yang dilakukan antara lain: karakteristik fisik meliputi organoleptis, homogenitas, pH, viskositas, daya lekat, daya sebar dan indeks iritasi

STIFERASTIFERA Kualitas pengawet kitosan lebih baik dibandingkan dengan kitin, yang ditandai dengan munculnya warna coklat dan bau masam pada mi basah oleh adanya pengawetKualitas pengawet kitosan lebih baik dibandingkan dengan kitin, yang ditandai dengan munculnya warna coklat dan bau masam pada mi basah oleh adanya pengawet