UMSIDAUMSIDA

Journal of Tropical Food and Agroindustrial TechnologyJournal of Tropical Food and Agroindustrial TechnologyThis study investigates the effect of slope angle and forward operating speed on the optimal performance of the harvesting process of a combine equipped with a decelerating pendulum device that mechanically and hydraulically changes the angle of inclination of the combine. Three harvesting slope angles (0-5°, 10-15° and 20-25°) and three forward speeds (3, 5 and 7 km/h) were tested using a New Holland TC54 harvester. The experiment was carried out using a randomised complete block design (RCBD) with (27) experimental units distributed in three replications. Several key performance indicators were measured including: Fuel consumption (litres/hour), operational efficiency (%), harvester stability and total grain loss as a percentage. The results showed that soils with steeper slopes significantly increased fuel consumption and grain loss, while reducing machine stability. The best performance was achieved at a slope angle of (10-15°) and a speed of (5) km/h, with a field capacity of (5.60) tons/hour, fuel consumption of 24.10 liters/hour, and the lowest grain loss of (2.3%). The effects of slope and speed were found to be statistically significant (P < 0.05), reflecting the importance of improved combinations in significantly enhancing operational efficiency, reducing harvest losses, and thus improving the overall performance of the agricultural system.

The findings of this study demonstrate that both slope angle and forward speed significantly influence the performance of combine harvesters equipped with pendulum-based stabilization systems.Steeper slopes resulted in higher fuel use and reduced machine stability, increasing grain loss.Moderate slope angles yielded optimal performance, with the highest effective field capacity and acceptable fuel consumption.Operating at 5 km/h offered the best balance between productivity and energy efficiency.The optimal configuration of a 10–15° slope at 5 km/h can significantly improve harvesting outcomes, minimizing grain loss and fuel use while enhancing operational capacity.

Penelitian lebih lanjut perlu dilakukan untuk mengeksplorasi pengaruh jangka panjang dari penggunaan sistem pendulum terhadap keausan mekanis mesin pemanen, serta efisiensi energi dan respons tanaman terhadap berbagai kondisi kemiringan dan kecepatan. Selain itu, pengembangan sistem kontrol adaptif berbasis sensor yang dapat secara otomatis menyesuaikan parameter operasi mesin pemanen berdasarkan kondisi medan secara *real-time* dapat meningkatkan efisiensi dan mengurangi kehilangan hasil panen. Terakhir, studi komparatif antara berbagai desain sistem pendulum dan dampaknya terhadap kinerja mesin pemanen pada berbagai jenis tanah dan iklim juga perlu dilakukan untuk mengidentifikasi solusi yang paling efektif dan berkelanjutan bagi petani.

| File size | 519.43 KB |

| Pages | 7 |

| DMCA | Report |

Related /

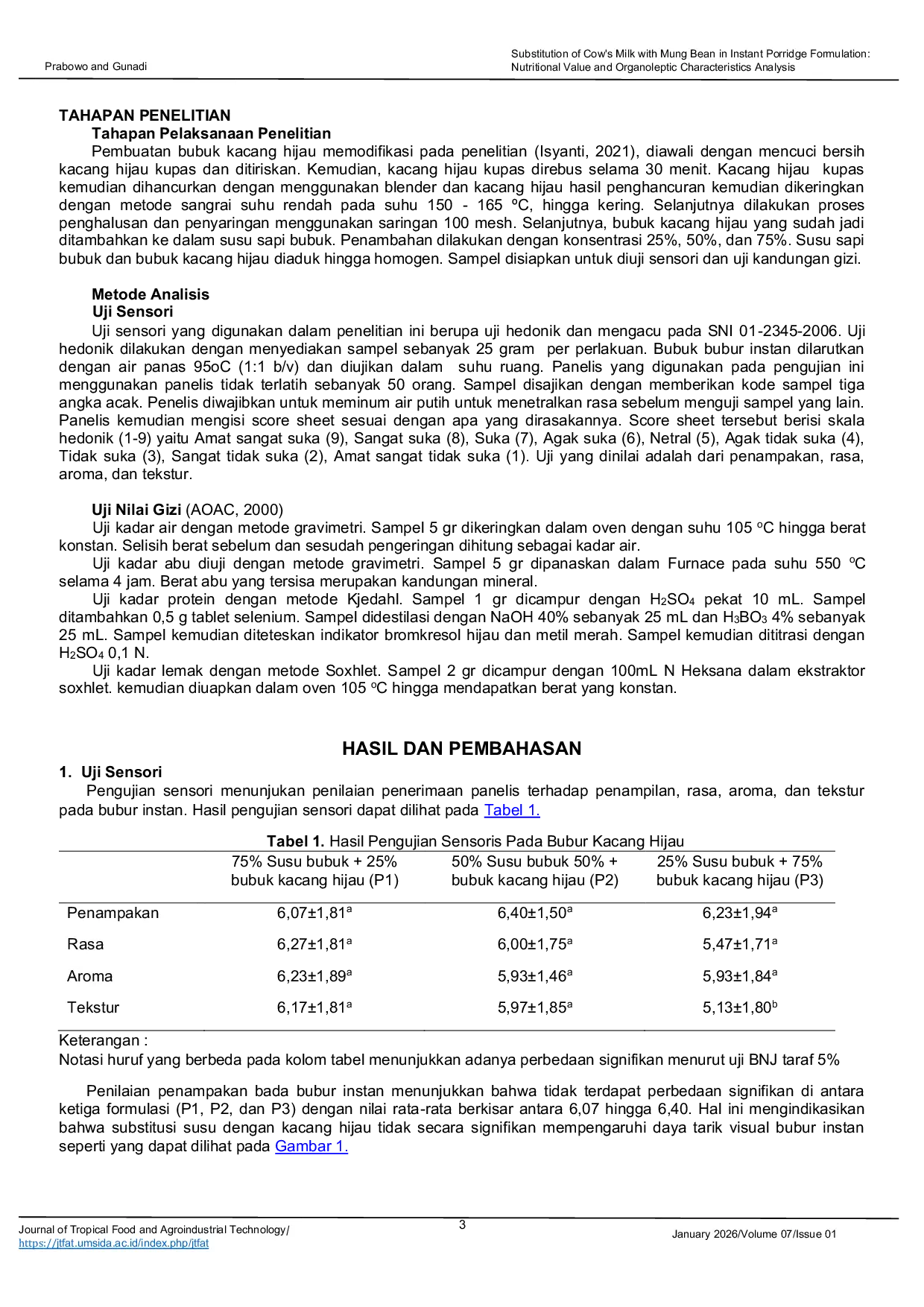

UMSIDAUMSIDA Uji organoleptik dilaksanakan menggunakan metode hedonik pada atribut penampakan, rasa, aroma, dan tekstur dengan melibatkan 50 panelis tidak terlatih.Uji organoleptik dilaksanakan menggunakan metode hedonik pada atribut penampakan, rasa, aroma, dan tekstur dengan melibatkan 50 panelis tidak terlatih.

STIKESRSANWARMEDIKASTIKESRSANWARMEDIKA Penelitian ini menganalisis tingkat aktivitas fisik mahasiswa di Jawa Timur. Metode penelitian yang digunakan adalah cross-sectional study yang melibatkanPenelitian ini menganalisis tingkat aktivitas fisik mahasiswa di Jawa Timur. Metode penelitian yang digunakan adalah cross-sectional study yang melibatkan

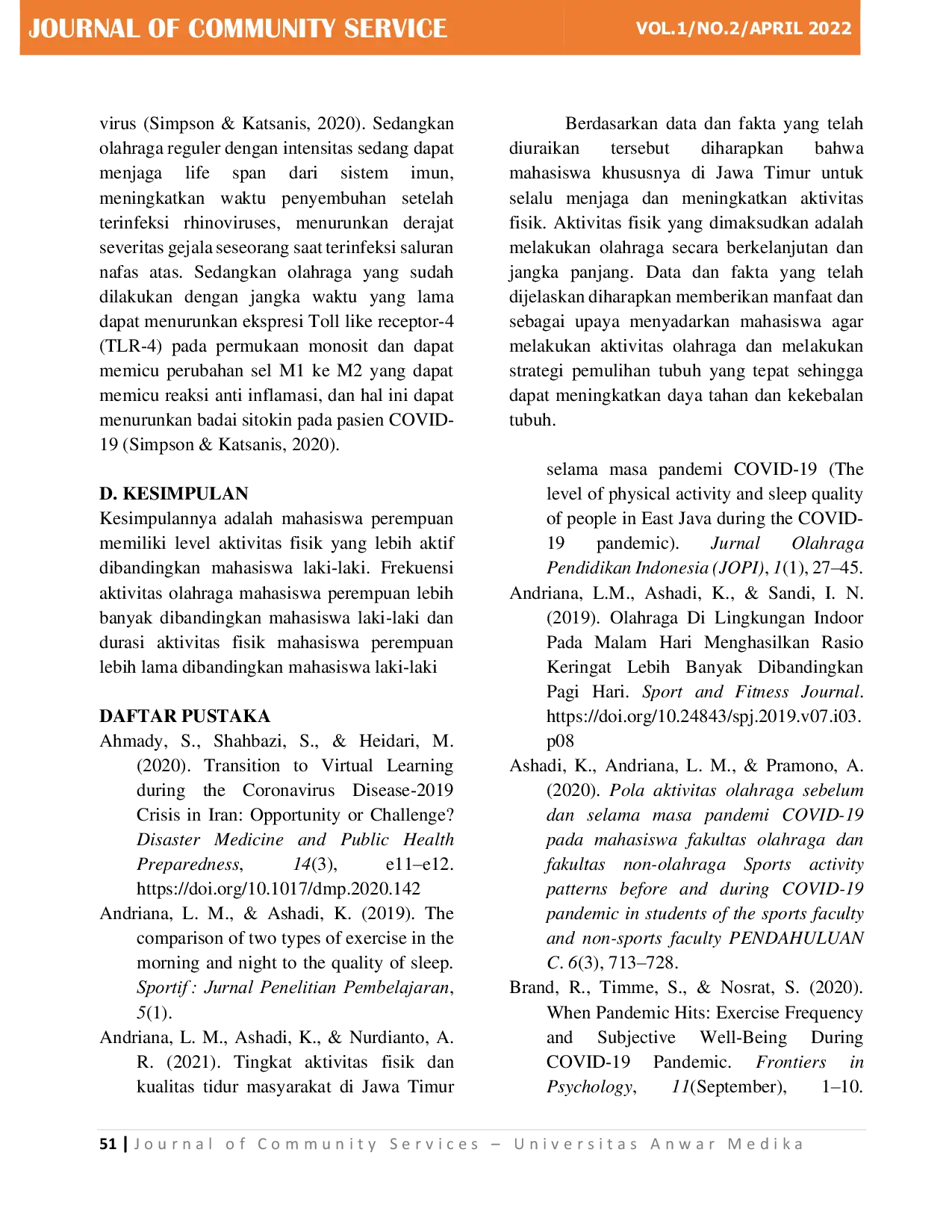

STIKESRSANWARMEDIKASTIKESRSANWARMEDIKA Metode penyampaian pengabdian masyarakat dilakukan dengan cara sosialisasi dan pembagian brosur tentang Resistensi Antibiotik kepada masyarakat Desa Sedenganmijen.Metode penyampaian pengabdian masyarakat dilakukan dengan cara sosialisasi dan pembagian brosur tentang Resistensi Antibiotik kepada masyarakat Desa Sedenganmijen.

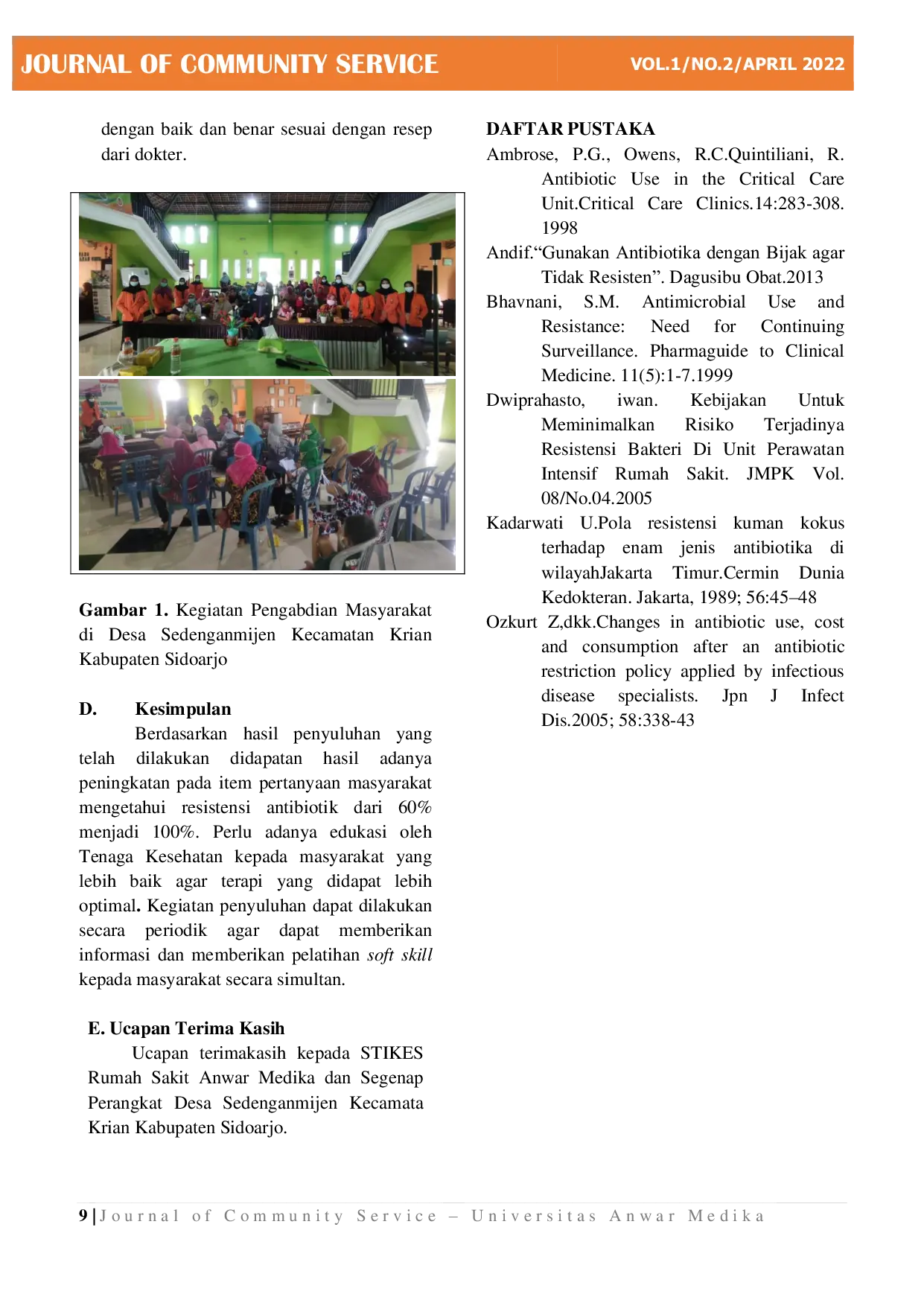

STIKESRSANWARMEDIKASTIKESRSANWARMEDIKA Kesimpulan: Inovasi POJOK PITU dapat meningkatkan angka kepatuhan pasien dalam meminum obat dan kunjungan rutin pasien pada Posyandu di Jiwa di Desa sehinggaKesimpulan: Inovasi POJOK PITU dapat meningkatkan angka kepatuhan pasien dalam meminum obat dan kunjungan rutin pasien pada Posyandu di Jiwa di Desa sehingga

YANAYANA The research demonstrates that the Telinggo learning media is valid, practical, and effective for use in flat shape learning. The media received high validationThe research demonstrates that the Telinggo learning media is valid, practical, and effective for use in flat shape learning. The media received high validation

YANAYANA Upaya guru Pendidikan Agama Islam (PAI) di MTs Al-Ikhlas dalam meningkatkan kegiatan keagamaan terwujud melalui pendirian doa bersama keliling, yang dimulaiUpaya guru Pendidikan Agama Islam (PAI) di MTs Al-Ikhlas dalam meningkatkan kegiatan keagamaan terwujud melalui pendirian doa bersama keliling, yang dimulai

ALFITHRAHALFITHRAH Rekomendasi yang dihasilkan dari penelitian ini mencakup pengembangan program pelatihan berkelanjutan, peningkatan insentif bagi karyawan, serta strategiRekomendasi yang dihasilkan dari penelitian ini mencakup pengembangan program pelatihan berkelanjutan, peningkatan insentif bagi karyawan, serta strategi

ALFITHRAHALFITHRAH Deskriptif kualitatif ialah data yang berupa kata-kata, gambar dan bukan angka-angka. Data primer dalam penelitian ini ialah wawacara dengan pempinan BMTDeskriptif kualitatif ialah data yang berupa kata-kata, gambar dan bukan angka-angka. Data primer dalam penelitian ini ialah wawacara dengan pempinan BMT

Useful /

UMSIDAUMSIDA Sifat amilografi tepung ampas tahu memperlihatkan laju gelatinisasi pati 13 menit, viskositas 48 cP, breakdown viscosity 11 cP, setback 16 cP, danSifat amilografi tepung ampas tahu memperlihatkan laju gelatinisasi pati 13 menit, viskositas 48 cP, breakdown viscosity 11 cP, setback 16 cP, dan

IPINTERNASIONALIPINTERNASIONAL Melalui kegiatan ini, tim pengabdian memberikan pelatihan dan bimbingan dalam teknik pengolahan pakan seperti fermentasi, silase, dan produksi pakan lengkapMelalui kegiatan ini, tim pengabdian memberikan pelatihan dan bimbingan dalam teknik pengolahan pakan seperti fermentasi, silase, dan produksi pakan lengkap

PUTRAGALUHPUTRAGALUH Hasil analisis menunjukkan adanya peningkatan signifikan pada rata-rata nilai siswa dari 55,04 saat pretest menjadi 79,96 saat posttest. Penurunan standarHasil analisis menunjukkan adanya peningkatan signifikan pada rata-rata nilai siswa dari 55,04 saat pretest menjadi 79,96 saat posttest. Penurunan standar

YANAYANA The research method used in this study is qualitative with a descriptive case study approach. Data and research sources are from the results of interviews,The research method used in this study is qualitative with a descriptive case study approach. Data and research sources are from the results of interviews,