UMJ PremiumUMJ Premium

International Conference on Engineering, Applied Sciences and TechnologyInternational Conference on Engineering, Applied Sciences and TechnologyThe andesite mining industry in Cilegon needs help in meeting the increasing market demand, especially in the Split 1-2 product, which has an annual production capacity of 349,418 tons compared to the demand of 454,238 tons. This research aims to increase production capacity through the application of the cut-and-try method. This method identifies the optimal solution through repeated experiments on various operational strategies. The analysis uses the Simple Moving Average, Exponential Moving Average, and Mean Absolute Percentage Error (MAPE) approaches for demand forecasting, as well as aggregate planning evaluation, to align capacity with market demand. The results show that the cut-and-try method provides flexibility in adjusting production strategies in real-time, allowing for increased productivity, reduced downtime, and more efficient inventory management. Two production planning scenarios were tested, namely Production Plan 1, with variations in inventory and stock depletion, and Production Plan 2, which uses constant labour and overtime. Of these two scenarios, Production Plan 2 proved to be more cost-effective, with a total expenditure of IDR 1,413,258,340 compared to IDR 2,357,596,694 in Production Plan 1.

The cut-and-try method offers a flexible approach to identifying effective production strategies in andesite mining through experimentation and real-time adjustments.This method allows for optimization of mining operations by testing various factors like labor, equipment, and inventory management, ultimately increasing efficiency and productivity.However, balancing flexibility with cost control is crucial, and a systematic approach using collected data can improve decision-making for sustainable growth.

Penelitian lebih lanjut dapat dilakukan untuk menguji efektivitas metode cut-and-try dalam berbagai kondisi geologis dan operasional tambang andesit, dengan mempertimbangkan faktor-faktor seperti karakteristik batuan, kedalaman tambang, dan kondisi cuaca. Selain itu, studi komparatif dapat dilakukan untuk membandingkan metode cut-and-try dengan metode optimasi produksi lainnya, seperti simulasi Monte Carlo atau algoritma genetika, untuk mengidentifikasi pendekatan yang paling efisien dan efektif dalam meningkatkan kapasitas produksi. Terakhir, penelitian dapat difokuskan pada pengembangan model prediktif yang lebih akurat untuk memperkirakan permintaan pasar dan mengoptimalkan perencanaan produksi, dengan memanfaatkan teknik machine learning dan analisis data besar untuk mengidentifikasi pola dan tren yang relevan.

| File size | 508.98 KB |

| Pages | 8 |

| DMCA | Report |

Related /

PENELITIPENELITI The application of Information Technology plays a significant role in supporting the marketing strategy of tourism villages. The potential of informationThe application of Information Technology plays a significant role in supporting the marketing strategy of tourism villages. The potential of information

ESC IDESC ID Saran yang dapat diambil dari hasil penelitian ini adalah PT. VCS disarankan untuk mempertimbangkan berbagai strategi untuk meningkatkan penjualan, sepertiSaran yang dapat diambil dari hasil penelitian ini adalah PT. VCS disarankan untuk mempertimbangkan berbagai strategi untuk meningkatkan penjualan, seperti

POLIBATAMPOLIBATAM Proses desain meliputi lima tahap: empati, definisi, ideasi, prototipe, dan pengujian. Data dikumpulkan melalui wawancara dan kuesioner kepada penggunaProses desain meliputi lima tahap: empati, definisi, ideasi, prototipe, dan pengujian. Data dikumpulkan melalui wawancara dan kuesioner kepada pengguna

PSEBPSEB Key findings include the calculation of Break Even Point (BEP) for the entire business and individual products, providing strategic insights for decisionKey findings include the calculation of Break Even Point (BEP) for the entire business and individual products, providing strategic insights for decision

UMSUMS Rata-rata penggunaan air masyarakat sebelum pandemi adalah 188,47 L per orang per hari. Jumlah ini meningkat menjadi 201 L per orang per hari selama pandemi.Rata-rata penggunaan air masyarakat sebelum pandemi adalah 188,47 L per orang per hari. Jumlah ini meningkat menjadi 201 L per orang per hari selama pandemi.

UMSUMS Meskipun terdapat tantangan, hasil evaluasi menyoroti potensi DCP dalam memprediksi variabilitas suhu permukaan di Asia Tenggara pada periode dekadal,Meskipun terdapat tantangan, hasil evaluasi menyoroti potensi DCP dalam memprediksi variabilitas suhu permukaan di Asia Tenggara pada periode dekadal,

ESC IDESC ID Dengan pendekatan kuantitatif dan desain penelitian kausal, penelitian melibatkan 43 karyawan sebagai populasi dan sampel. Data yang digunakan terdiriDengan pendekatan kuantitatif dan desain penelitian kausal, penelitian melibatkan 43 karyawan sebagai populasi dan sampel. Data yang digunakan terdiri

ESC IDESC ID Sampel yang digunakan berjumlah 50 responden yang merupakan konsumen dengan usia lebih dari 17 tahun dengan minimal satu kali pembelian di Mixue MojokertoSampel yang digunakan berjumlah 50 responden yang merupakan konsumen dengan usia lebih dari 17 tahun dengan minimal satu kali pembelian di Mixue Mojokerto

Useful /

POLIBATAMPOLIBATAM Studi ini bertujuan untuk mereview secara sistematis topik tersebut dengan mengatasi tiga pertanyaan penelitian utama: (1) Sejauh mana konsumsi UPF memengaruhiStudi ini bertujuan untuk mereview secara sistematis topik tersebut dengan mengatasi tiga pertanyaan penelitian utama: (1) Sejauh mana konsumsi UPF memengaruhi

UMSUMS Sebaliknya, bagian hilir basin karakteristiknya kemiringan yang sangat landai dan tingkat fraktur rendah hingga tidak ada, yang mengurangi kerentanan terhadapSebaliknya, bagian hilir basin karakteristiknya kemiringan yang sangat landai dan tingkat fraktur rendah hingga tidak ada, yang mengurangi kerentanan terhadap

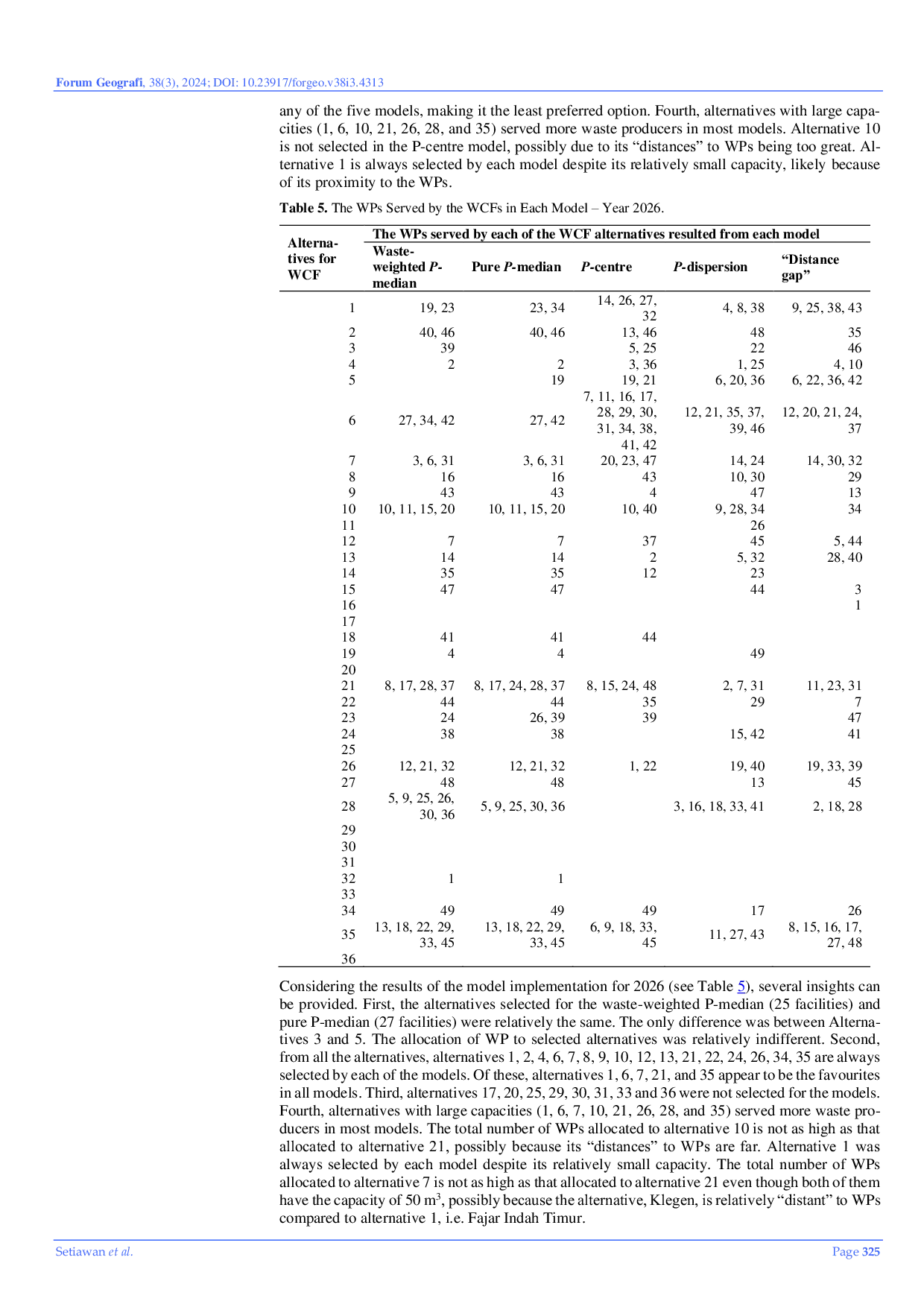

UMSUMS Kami mengusulkan beberapa model lokasi-alokasi—yaitu P-median tertimbang sampah, P-median murni, P-center, P-dispersi, dan model distance gap—untukKami mengusulkan beberapa model lokasi-alokasi—yaitu P-median tertimbang sampah, P-median murni, P-center, P-dispersi, dan model distance gap—untuk

ESC IDESC ID Sampel penelitian terdiri dari 226 perusahaan manufaktur yang terdaftar di Bursa Efek Indonesia selama periode 2019-2022, dengan teknik purposive samplingSampel penelitian terdiri dari 226 perusahaan manufaktur yang terdaftar di Bursa Efek Indonesia selama periode 2019-2022, dengan teknik purposive sampling