ATTRACTIVEJOURNALATTRACTIVEJOURNAL

Asian Journal Science and EngineeringAsian Journal Science and EngineeringThis study aims to evaluate the quality control of lightweight brick production at PT XYZ using the Fault Tree Analysis (FTA) method. In the manufacturing industry, product defects are a major challenge that can affect production efficiency, operating costs, and company competitiveness. Based on production data from January to December 2024, the total number of defects identified reached 125,334 units, consisting of three main types, namely cracks (63%), peeling (21%), and imprecision (16%). Through the application of FTA, this study revealed that the two dominant factors that are the root causes of product defects are human error and tools or equipment. Human error is mainly triggered by operator carelessness, overly rapid mold dismantling processes, and errors in installing cutting tools. Meanwhile, machine factors include worn components, excessive vibration, deteriorating cutting wire quality, and lack of regular maintenance. The results of the study emphasize the need for a comprehensive improvement strategy through increasing operator competence, enforcing work discipline, scheduled machine maintenance, and standardizing operational procedures. The implementation of these improvements is expected to reduce the defect rate and improve product quality in a sustainable manner.

The study concludes that the defect rate of lightweight brick products at PT XYZ from January to December 2024 was dominated by cracks (63%), followed by peeling (21%), and imprecision (16%), totaling 125,334 defective units.The main source of defects stemmed from a combination of human error and machine/equipment factors, leading to inconsistencies in product quality.Improving product quality requires a comprehensive strategy encompassing operator training and discipline, enhanced supervision, and a planned machine maintenance system to reduce defects and ensure consistent production quality.

Based on the findings, future research could explore the integration of real-time monitoring systems with FTA to predict and prevent defects before they occur, potentially utilizing machine learning algorithms to identify patterns indicative of impending failures. Furthermore, a comparative study analyzing the effectiveness of different maintenance strategies – such as predictive versus preventative maintenance – on reducing equipment-related defects would be valuable. Finally, investigating the psychological factors influencing operator error, such as workload and stress levels, and developing targeted interventions to improve operator focus and adherence to procedures, could significantly contribute to enhancing product quality and reducing human-induced defects.

| File size | 927.95 KB |

| Pages | 19 |

| Short Link | https://juris.id/p-38Q |

| Lookup Links | Google ScholarGoogle Scholar, Semantic ScholarSemantic Scholar, CORE.ac.ukCORE.ac.uk, WorldcatWorldcat, ZenodoZenodo, Research GateResearch Gate, Academia.eduAcademia.edu, OpenAlexOpenAlex, Hollis HarvardHollis Harvard |

| DMCA | Report |

Related /

STIM LPISTIM LPI Hasil analisis regresi linier berganda menunjukkan bahwa harga berpengaruh positif dan signifikan terhadap keputusan pembelian di Alfamidi wonomulyo, KualitasHasil analisis regresi linier berganda menunjukkan bahwa harga berpengaruh positif dan signifikan terhadap keputusan pembelian di Alfamidi wonomulyo, Kualitas

UNP KEDIRIUNP KEDIRI Hasil Asesmen Nasional pada beberapa Sekolah Dasar Negeri di Kecamatan Tulungagung menunjukkan adanya variasi capaian yang signifikan antar sekolah. KondisiHasil Asesmen Nasional pada beberapa Sekolah Dasar Negeri di Kecamatan Tulungagung menunjukkan adanya variasi capaian yang signifikan antar sekolah. Kondisi

UNP KEDIRIUNP KEDIRI Penelitian ini menyimpulkan bahwa literasi keuangan dan gaya hidup hedonis secara signifikan memengaruhi perilaku konsumtif Gen Z, sementara self-controlPenelitian ini menyimpulkan bahwa literasi keuangan dan gaya hidup hedonis secara signifikan memengaruhi perilaku konsumtif Gen Z, sementara self-control

UNP KEDIRIUNP KEDIRI Terdapat 100 sampel yang digunakan dalam penelitian yang dianalisis melalui perangkat lunak SmartPLS versi 4. 0 dengan metode PLS SEM. Hasil temuan memperlihatkanTerdapat 100 sampel yang digunakan dalam penelitian yang dianalisis melalui perangkat lunak SmartPLS versi 4. 0 dengan metode PLS SEM. Hasil temuan memperlihatkan

UNP KEDIRIUNP KEDIRI Teknik analisis data yang digunakan yaitu regresi logistik biner untuk mengindentifikasi faktor-faktor yang berpengaruh terhadap kualitas tidur remajaTeknik analisis data yang digunakan yaitu regresi logistik biner untuk mengindentifikasi faktor-faktor yang berpengaruh terhadap kualitas tidur remaja

UNP KEDIRIUNP KEDIRI Penelitian ini dilakukan melalui metode studi pustaka yang menganalisis literatur terkait pengembangan motorik halus yang relevan untuk anak dengan disgrafia.Penelitian ini dilakukan melalui metode studi pustaka yang menganalisis literatur terkait pengembangan motorik halus yang relevan untuk anak dengan disgrafia.

UMMUMM Penelitian menggunakan metode penelitian deskriptif kualitatif dan data penelitian diperoleh dari penjual dan pembeli buah yang bersorak harga terkecil.Penelitian menggunakan metode penelitian deskriptif kualitatif dan data penelitian diperoleh dari penjual dan pembeli buah yang bersorak harga terkecil.

ILOMATAILOMATA Penelitian ini bertujuan untuk memberikan bukti empiris mengenai pengaruh kualitas produk, kualitas layanan, dan harga terhadap keputusan pembelian produkPenelitian ini bertujuan untuk memberikan bukti empiris mengenai pengaruh kualitas produk, kualitas layanan, dan harga terhadap keputusan pembelian produk

Useful /

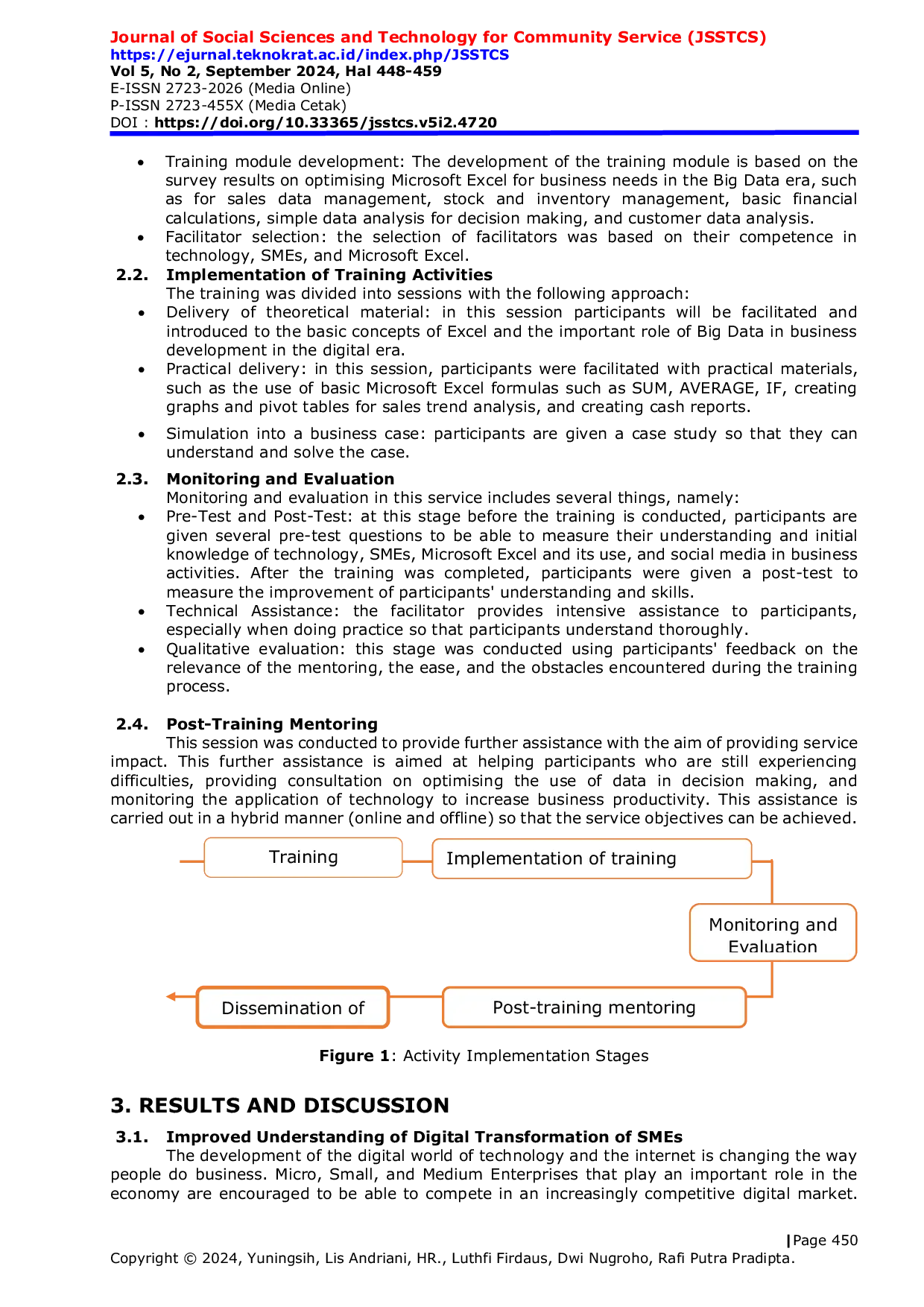

TEKNOKRATTEKNOKRAT Pelatihan ini juga menekankan pentingnya strategi pemasaran digital yang terukur dan berkelanjutan, yang memberikan dasar yang kuat bagi UMKM untuk bersaingPelatihan ini juga menekankan pentingnya strategi pemasaran digital yang terukur dan berkelanjutan, yang memberikan dasar yang kuat bagi UMKM untuk bersaing

TEKNOKRATTEKNOKRAT However, in-depth material is still needed, so further training is needed to deepen the knowledge and skills of SMEs actors. This is important for SMEsHowever, in-depth material is still needed, so further training is needed to deepen the knowledge and skills of SMEs actors. This is important for SMEs

UMMUMM Oleh karena itu, semua masalah yang menghambat dan mengganggu bisnis pinjaman online harus segera ditangani oleh pemerintah dengan membentuk undang-undangOleh karena itu, semua masalah yang menghambat dan mengganggu bisnis pinjaman online harus segera ditangani oleh pemerintah dengan membentuk undang-undang

UMMUMM Indonesia adalah negara yang menganut sistem hukum perdata, di mana setiap pengaturan hukum harus didasarkan pada hukum tertulis. Kekurangan dari sistemIndonesia adalah negara yang menganut sistem hukum perdata, di mana setiap pengaturan hukum harus didasarkan pada hukum tertulis. Kekurangan dari sistem