IDUIDU

MUNISI: Military Mathematics and Natural SciencesMUNISI: Military Mathematics and Natural SciencesConventional plastic waste is difficult to decompose and has the potential to leave traces in the TNI field of operations. This condition has encouraged the development of polysaccharide-based bioplastics as a safe, environmentally friendly, and easily degradable alternative for ration packaging. This study aims to optimize the concentration of carboxymethylcellulose (CMC) as a filler in the formulation of polysaccharide bioplastics for TNI ration packaging. The method used was a literature review on the effect of CMC addition on the physical and mechanical properties of bioplastic films. The results of the study showed that the addition of CMC generally increased tensile strength and water absorption, but also accelerated dissolution and the rate of biodegradation. The optimum concentration varied depending on the type of polymer used. Therefore, the selection of CMC concentration must be adjusted to the application objective, whether to increase mechanical strength or accelerate biodegradation, and needs to be validated through mechanical and degradation tests under real conditions. Compliance with bioplastic quality standards and the use of safe additives are highly recommended for application in TNI ration packaging.

Literature analysis shows that increasing the CMC concentration generally increases the tensile strength and water absorption of bioplastics, but also accelerates solubility and the rate of biodegradation, necessitating a tailored formulation to meet the required mechanical and durability standards.Determining the optimal concentration depends on the application objective.It is necessary to conduct mechanical testing and further degradation testing under real application conditions before finalizing the formulation.

Penelitian lebih lanjut perlu dilakukan untuk menguji performa bioplastik berbasis CMC dalam kondisi lapangan yang sebenarnya, termasuk paparan terhadap berbagai faktor lingkungan seperti suhu ekstrem, kelembaban, dan mikroorganisme. Selain itu, studi komparatif perlu dilakukan untuk membandingkan bioplastik berbasis CMC dengan jenis bioplastik lainnya, seperti PLA atau PHA, dalam hal sifat mekanik, biodegradabilitas, dan biaya produksi, untuk menentukan opsi yang paling optimal untuk aplikasi pengemasan ransum TNI. Terakhir, penelitian perlu difokuskan pada pengembangan metode produksi bioplastik berbasis CMC yang lebih efisien dan berkelanjutan, termasuk penggunaan sumber CMC yang terbarukan dan ramah lingkungan, serta pengurangan penggunaan bahan kimia berbahaya dalam proses produksi.

| File size | 493.75 KB |

| Pages | 14 |

| DMCA | Report |

Related /

UNUGHAUNUGHA Penelitian ini bertujuan untuk mengeksplorasi tantangan dan peluang yang dihadapi oleh Mikro, Kecil, dan Menengah (MSME) dalam menerapkan prinsip-prinsipPenelitian ini bertujuan untuk mengeksplorasi tantangan dan peluang yang dihadapi oleh Mikro, Kecil, dan Menengah (MSME) dalam menerapkan prinsip-prinsip

UNUGHAUNUGHA Untuk mengatasi tantangan yang dihadapi oleh Kelompok Pengolahan dan Pemasaran Produk Ikan Olahan di Desa Ulak Karang Utara, Kota Padang, yang meliputiUntuk mengatasi tantangan yang dihadapi oleh Kelompok Pengolahan dan Pemasaran Produk Ikan Olahan di Desa Ulak Karang Utara, Kota Padang, yang meliputi

STPI PAJAKSTPI PAJAK Metode penelitian yang digunakan adalah campuran (mixed method), dengan pendekatan kuantitatif untuk memperoleh data numerik serta kualitatif untuk mendapatkanMetode penelitian yang digunakan adalah campuran (mixed method), dengan pendekatan kuantitatif untuk memperoleh data numerik serta kualitatif untuk mendapatkan

UNSERAUNSERA Kegiatan pengabdian kepada masyarakat ini bertujuan untuk memberdayakan Usaha Mikro, Kecil, dan Menengah (UMKM) “Emping Bu Mulyati melalui penguatanKegiatan pengabdian kepada masyarakat ini bertujuan untuk memberdayakan Usaha Mikro, Kecil, dan Menengah (UMKM) “Emping Bu Mulyati melalui penguatan

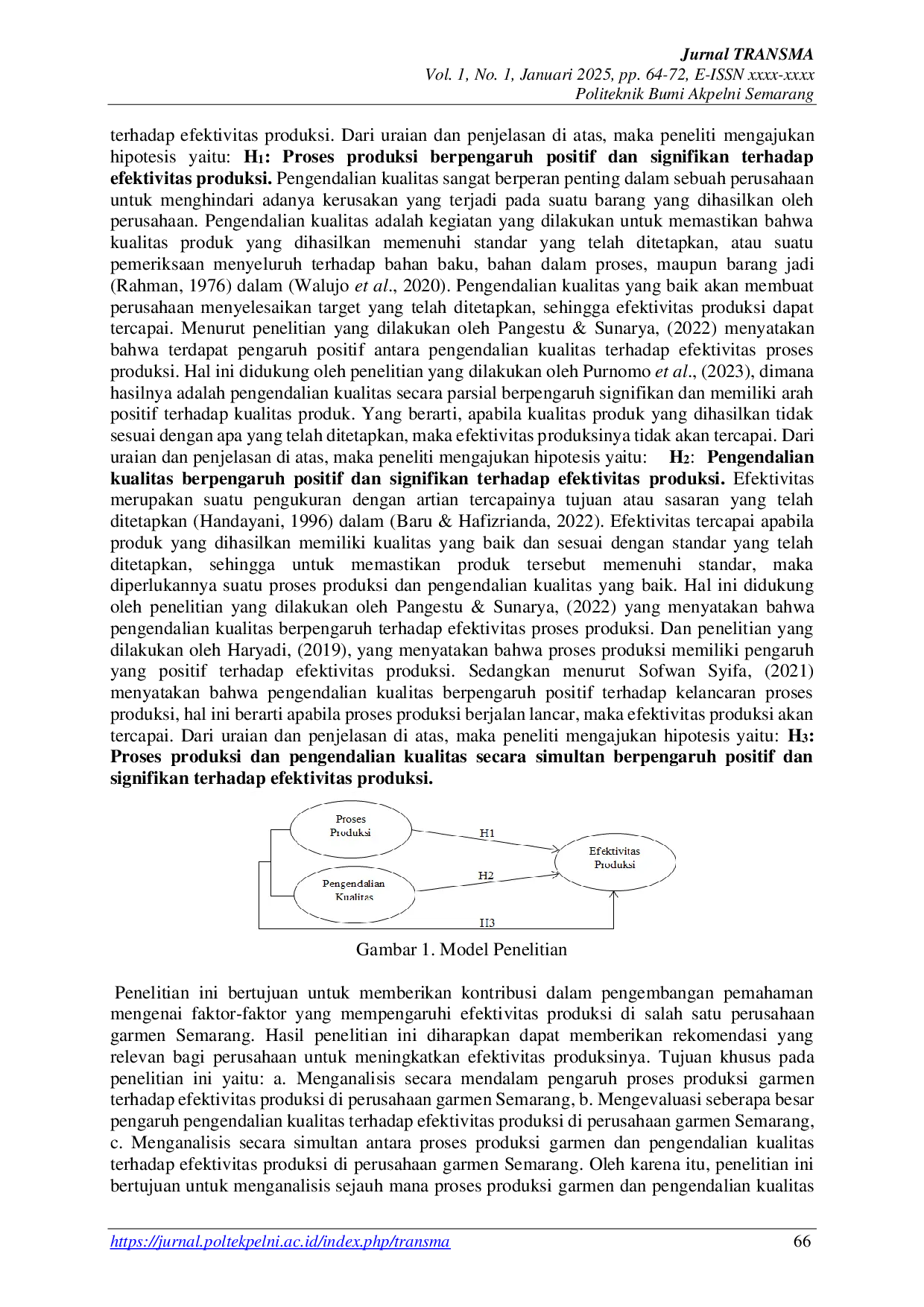

POLTEKPELNIPOLTEKPELNI Secara simultan proses produksi dan pengendalian kualitas berpengaruh positif dan signifikan terhadap efektivitas produksi yang dimana nilai signifikansiSecara simultan proses produksi dan pengendalian kualitas berpengaruh positif dan signifikan terhadap efektivitas produksi yang dimana nilai signifikansi

IAFORISIAFORIS Penelitian ini memiliki tujuan untuk memahami secara mendalam bagaimana urgensitas sertifikasi halal dalam pemberdayaan perempuan. Metode yang digunakanPenelitian ini memiliki tujuan untuk memahami secara mendalam bagaimana urgensitas sertifikasi halal dalam pemberdayaan perempuan. Metode yang digunakan

POLITAN IPYKPOLITAN IPYK Pada saluran pemasaran III, petani memperoleh harga sebesar Rp 25.722,22 per kg dengan farmer share sebesar 100% dan efisiensi pemasaran yaitu 1,77%. DariPada saluran pemasaran III, petani memperoleh harga sebesar Rp 25.722,22 per kg dengan farmer share sebesar 100% dan efisiensi pemasaran yaitu 1,77%. Dari

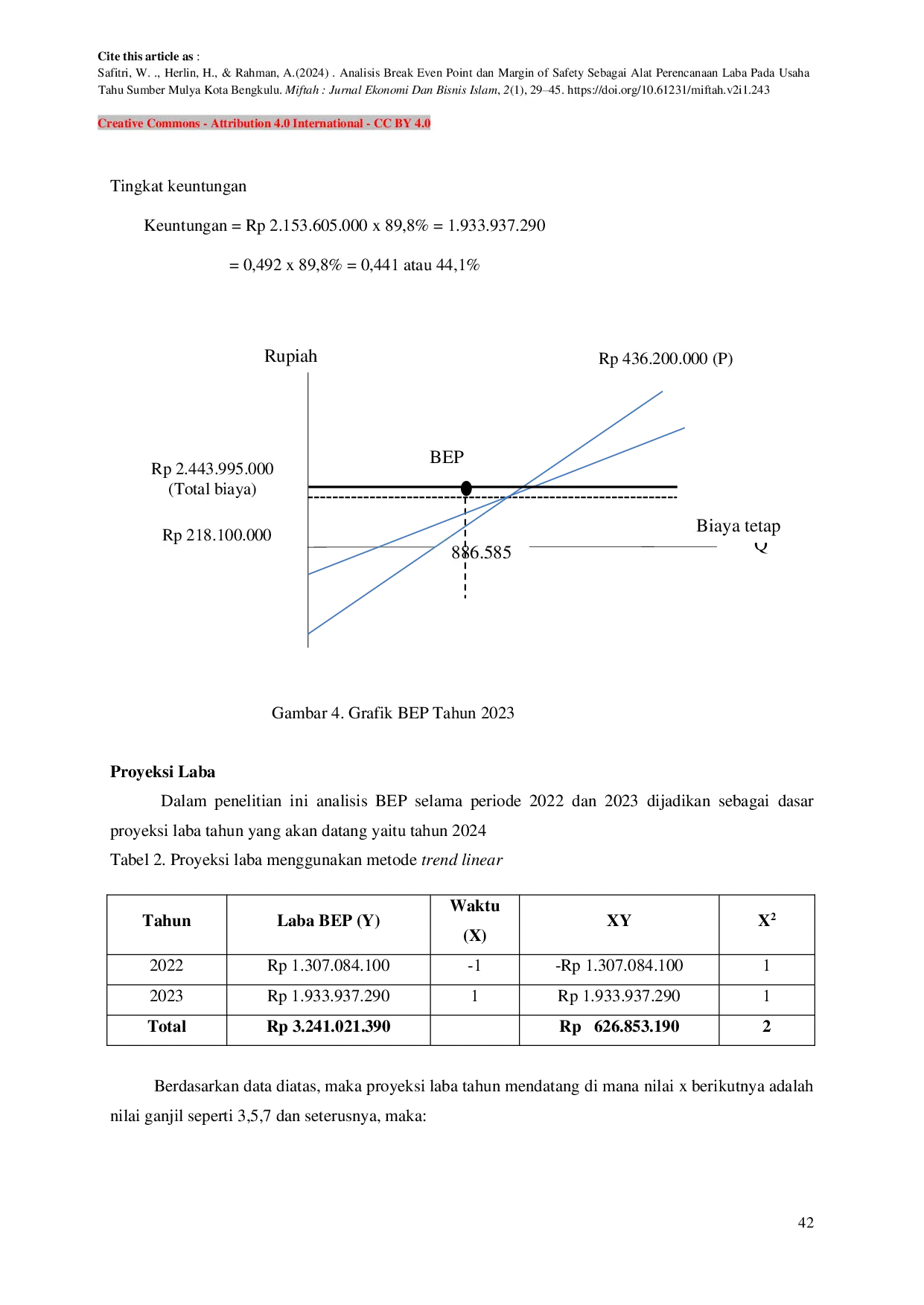

SUNANBONANGSUNANBONANG Analisis menunjukkan bahwa BEP pada tahun 2022 sebesar 1. 952) dengan margin of safety 86,1% dan pada tahun 2023 sebesar 886.000) dengan margin of safetyAnalisis menunjukkan bahwa BEP pada tahun 2022 sebesar 1. 952) dengan margin of safety 86,1% dan pada tahun 2023 sebesar 886.000) dengan margin of safety

Useful /

STPI PAJAKSTPI PAJAK Studi menunjukkan bahwa penerapan teknologi efisiensi energi seperti sistem manajemen energi gedung (BEMS) dan pencahayaan LED dapat menurunkan konsumsiStudi menunjukkan bahwa penerapan teknologi efisiensi energi seperti sistem manajemen energi gedung (BEMS) dan pencahayaan LED dapat menurunkan konsumsi

IDUIDU Namun, tidak ada perbedaan signifikan dalam pertumbuhan tanaman bok choy antara kedua sistem. Sistem IoT dapat memantau dan mengontrol kebutuhan tanamanNamun, tidak ada perbedaan signifikan dalam pertumbuhan tanaman bok choy antara kedua sistem. Sistem IoT dapat memantau dan mengontrol kebutuhan tanaman

STPI PAJAKSTPI PAJAK Hasil penelitian menunjukkan bahwa KPI berpengaruh positif dan signifikan terhadap kinerja SDM, dibuktikan dengan uji t sebesar 14,269 dan nilai signifikansiHasil penelitian menunjukkan bahwa KPI berpengaruh positif dan signifikan terhadap kinerja SDM, dibuktikan dengan uji t sebesar 14,269 dan nilai signifikansi

STPI PAJAKSTPI PAJAK Selain itu, keberadaan institutional shareholder berpengaruh positif terhadap investasi R&D. Manajemen perusahaan disarankan lebih memperhatikan keberagamanSelain itu, keberadaan institutional shareholder berpengaruh positif terhadap investasi R&D. Manajemen perusahaan disarankan lebih memperhatikan keberagaman