UBHUBH

ABSTRACT OF UNDERGRADUATE RESEARCH, FACULTY OF INDUSTRIAL TECHNOLOGY, BUNG HATTA UNIVERSITYABSTRACT OF UNDERGRADUATE RESEARCH, FACULTY OF INDUSTRIAL TECHNOLOGY, BUNG HATTA UNIVERSITYIn recent years, the use of natural fibers as a reinforcing medium that can replace synthetic fibers has experienced rapid development in composite materials. The negative effects of synthetic fibers whose waste is difficult to recycle and pollute the environment also encourage the use of natural fibers. So, using natural fibers that are good for the environment is a good idea to protect the environment. The aim of this research is to obtain tensile and bending strength values for the composite material of windwood bark powder with polyester resin. This was done by means of tensile testing and bending testing to find out test result data From the tensile test results, there is a relationship between the fraction of wind-blown bark powder in composition and the stress, strain and modulus of elasticity. Increasing the fraction of wind-blown bark powder resulted in a decrease in stress, strain and modulus of elasticity. This shows that the flexural strength of wind-blown bark powder is not optimal, as can be seen from the lower flexural strength values in the composition using this powder. The composition without air-turned sawdust had the highest flexural strength, while the composition with the 20:80% fraction had the lowest flexural strength, although there was an increase in the 30:70% composition.

Berdasarkan perhitungan data serta analisa, dapat disimpulkan bahwa semakin tinggi nilai tegangan maka material semakin ulet, dan semakin rendah nilai tegangan maka material semakin getas.Hasil pengujian lentur menunjukkan bahwa serbuk kulit kayu balik angin memiliki nilai lentur yang kurang baik, dengan kekuatan lentur tertinggi pada komposisi 0.80%, meskipun terjadi kenaikan pada komposisi 30.Penelitian ini memberikan pemahaman mengenai potensi dan keterbatasan serbuk kulit kayu balik angin sebagai penguat dalam material komposit berbasis polyester.

Penelitian lanjutan dapat difokuskan pada optimasi proses pembuatan komposit dengan variasi metode pencampuran dan tekanan untuk meningkatkan dispersi serbuk kulit kayu dalam matriks polyester, sehingga meningkatkan kekuatan mekaniknya. Selain itu, studi lebih mendalam mengenai perlakuan permukaan serbuk kulit kayu, seperti penggunaan bahan penghubung (coupling agent), dapat dilakukan untuk meningkatkan adhesi antara serbuk dan matriks, yang berpotensi meningkatkan kekuatan tarik dan lentur komposit. Terakhir, penelitian perlu dilakukan untuk mengeksplorasi potensi penggunaan serbuk kulit kayu balik angin dalam aplikasi komposit yang lebih spesifik, seperti material konstruksi ringan atau komponen otomotif, dengan mempertimbangkan faktor biaya dan keberlanjutan lingkungan.

| File size | 273.37 KB |

| Pages | 4 |

| Short Link | https://juris.id/p-3fe |

| Lookup Links | Google ScholarGoogle Scholar, Semantic ScholarSemantic Scholar, CORE.ac.ukCORE.ac.uk, WorldcatWorldcat, ZenodoZenodo, Research GateResearch Gate, Academia.eduAcademia.edu, OpenAlexOpenAlex, Hollis HarvardHollis Harvard |

| DMCA | Report |

Related /

POLMAN BABELPOLMAN BABEL Jenis kawat las yang digunakan adalah ER316L dengan diameter 1,6 mm dan argon sebagai gas pelindung serta menggunakan gas penyokong. Hasil pengamatan visualJenis kawat las yang digunakan adalah ER316L dengan diameter 1,6 mm dan argon sebagai gas pelindung serta menggunakan gas penyokong. Hasil pengamatan visual

UNSULTRAUNSULTRA Kegiatan ini menggunakan metode kualitatif dengan tahapan identifikasi masalah, edukasi potensi ekonomi, pelatihan teknis produksi arang, penguatan kolaborasiKegiatan ini menggunakan metode kualitatif dengan tahapan identifikasi masalah, edukasi potensi ekonomi, pelatihan teknis produksi arang, penguatan kolaborasi

APTKLHIAPTKLHI Hasil penelitian menunjukkan bahwa peningkatan fraksi serat Paederia foetida pada komposit hibrida CP/PFs secara signifikan meningkatkan kekuatan tarik,Hasil penelitian menunjukkan bahwa peningkatan fraksi serat Paederia foetida pada komposit hibrida CP/PFs secara signifikan meningkatkan kekuatan tarik,

UNYUNY Metode yang digunakan meliputi pulping, bleaching, dan pembuatan lembaran kertas, kemudian dibandingkan dengan kertas komersial. Hasilnya menunjukkan bahwaMetode yang digunakan meliputi pulping, bleaching, dan pembuatan lembaran kertas, kemudian dibandingkan dengan kertas komersial. Hasilnya menunjukkan bahwa

UMPUMP Sementara itu, tataran superstruktur mengikuti pola pendahuluan, isi, dan penutup, serta struktur mikro disajikan secara detail melalui aspek semantik,Sementara itu, tataran superstruktur mengikuti pola pendahuluan, isi, dan penutup, serta struktur mikro disajikan secara detail melalui aspek semantik,

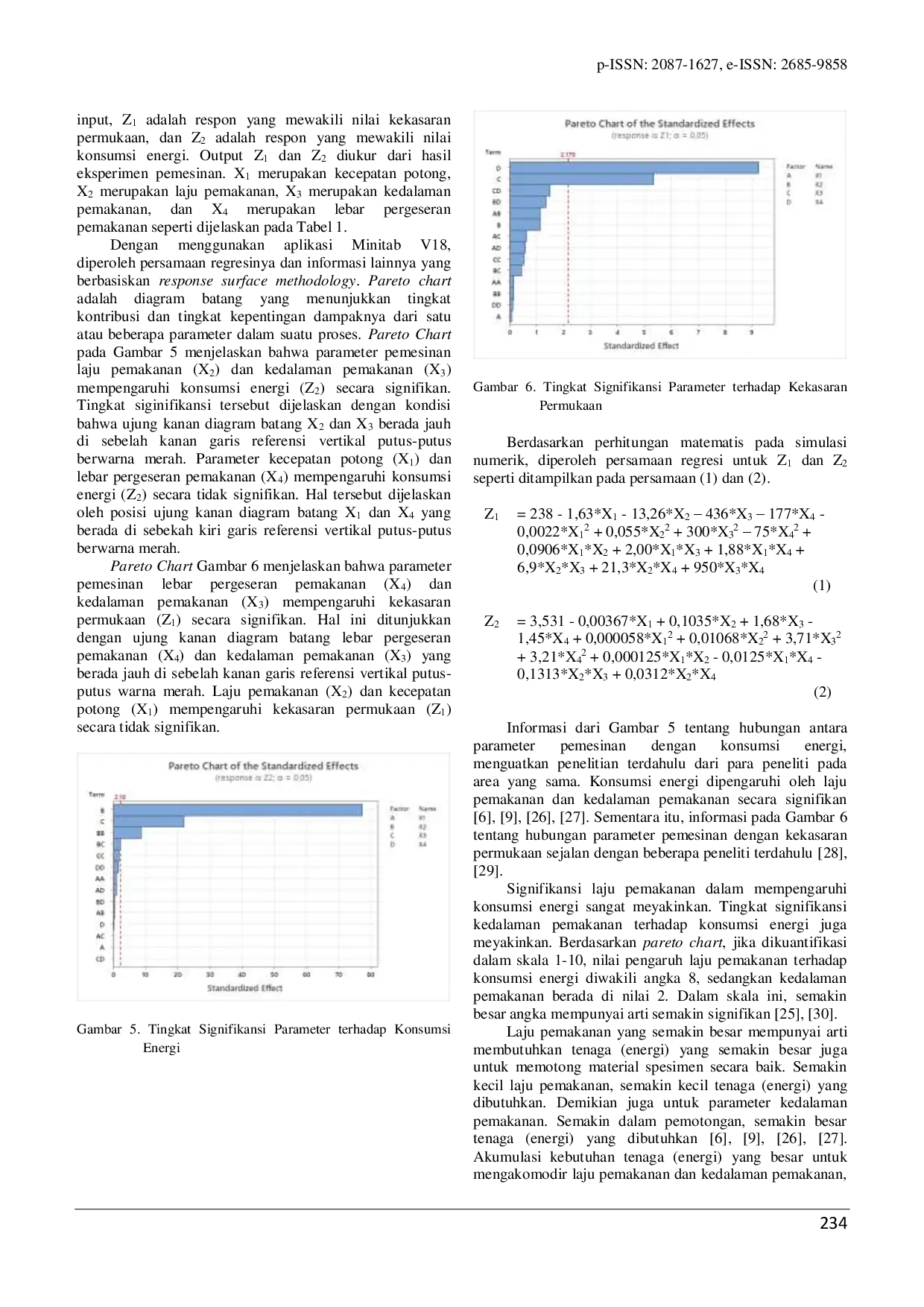

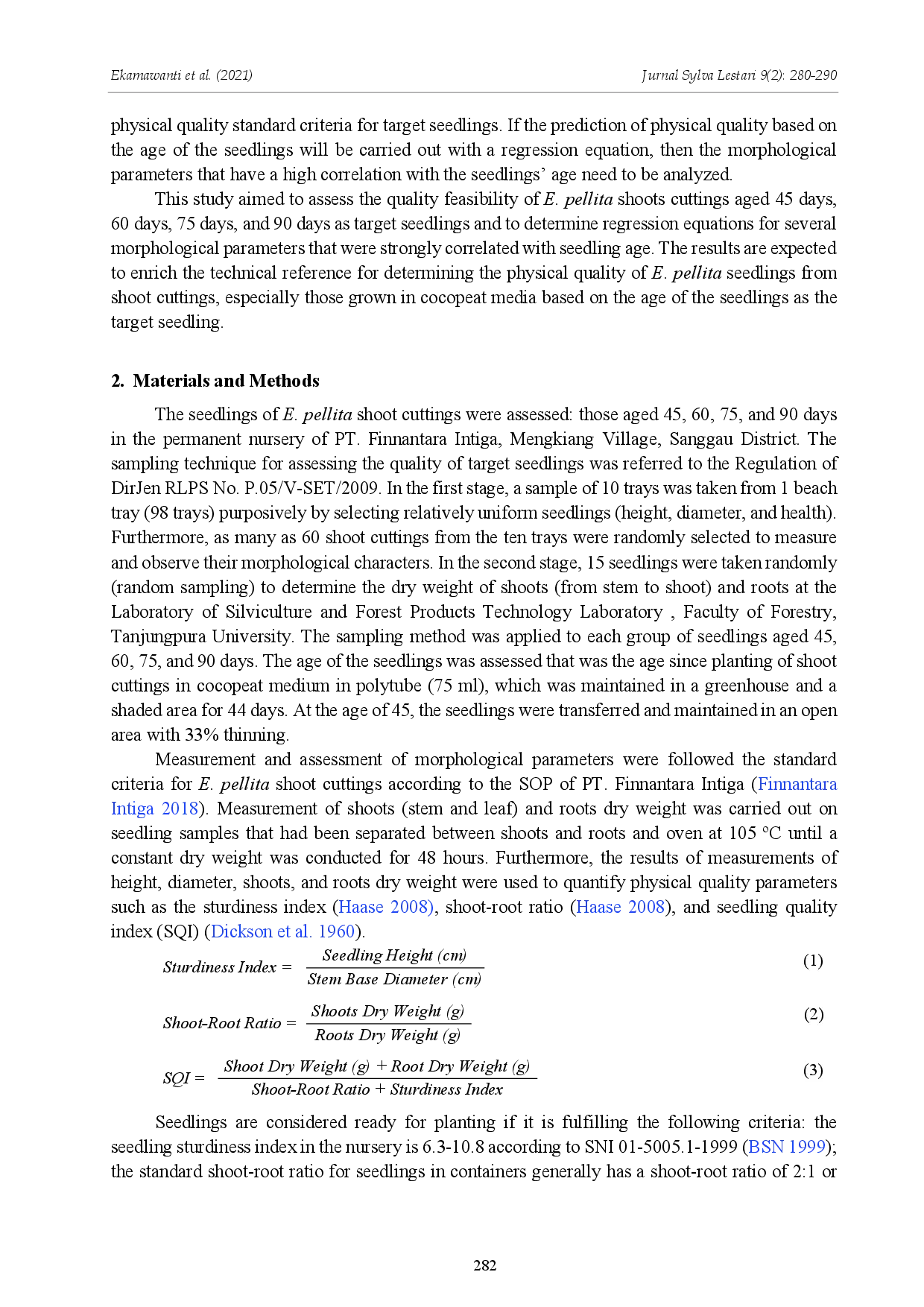

PNCPNC Industri mesin perkakas mengonsumsi sekitar 10% dari total energi nasional, menjadikan industri ini sebagai pengguna energi terbesar kedua setelah sektorIndustri mesin perkakas mengonsumsi sekitar 10% dari total energi nasional, menjadikan industri ini sebagai pengguna energi terbesar kedua setelah sektor

UNILAUNILA Hasil karakterisasi menunjukkan bahwa bioplastik komposit memiliki kekuatan tarik 7,8 MPa dan kelarutan dalam air 22%. Waktu degradasi bioplastik di tanahHasil karakterisasi menunjukkan bahwa bioplastik komposit memiliki kekuatan tarik 7,8 MPa dan kelarutan dalam air 22%. Waktu degradasi bioplastik di tanah

UNUSAUNUSA Hasil penelitian menunjukkan bahwa kertas yang dihasilkan memiliki gramatur 80 g/m², ketebalan 0,14 mm, kekuatan tarik 25 MPa, dan kadar air 7%. KertasHasil penelitian menunjukkan bahwa kertas yang dihasilkan memiliki gramatur 80 g/m², ketebalan 0,14 mm, kekuatan tarik 25 MPa, dan kadar air 7%. Kertas

Useful /

JK RISKJK RISK Pendekatan multimodalitas sangat dianjurkan untuk setiap skenario klinis pada individu dewasa muda. Prosedur skrining untuk individu tanpa gejala menjadiPendekatan multimodalitas sangat dianjurkan untuk setiap skenario klinis pada individu dewasa muda. Prosedur skrining untuk individu tanpa gejala menjadi

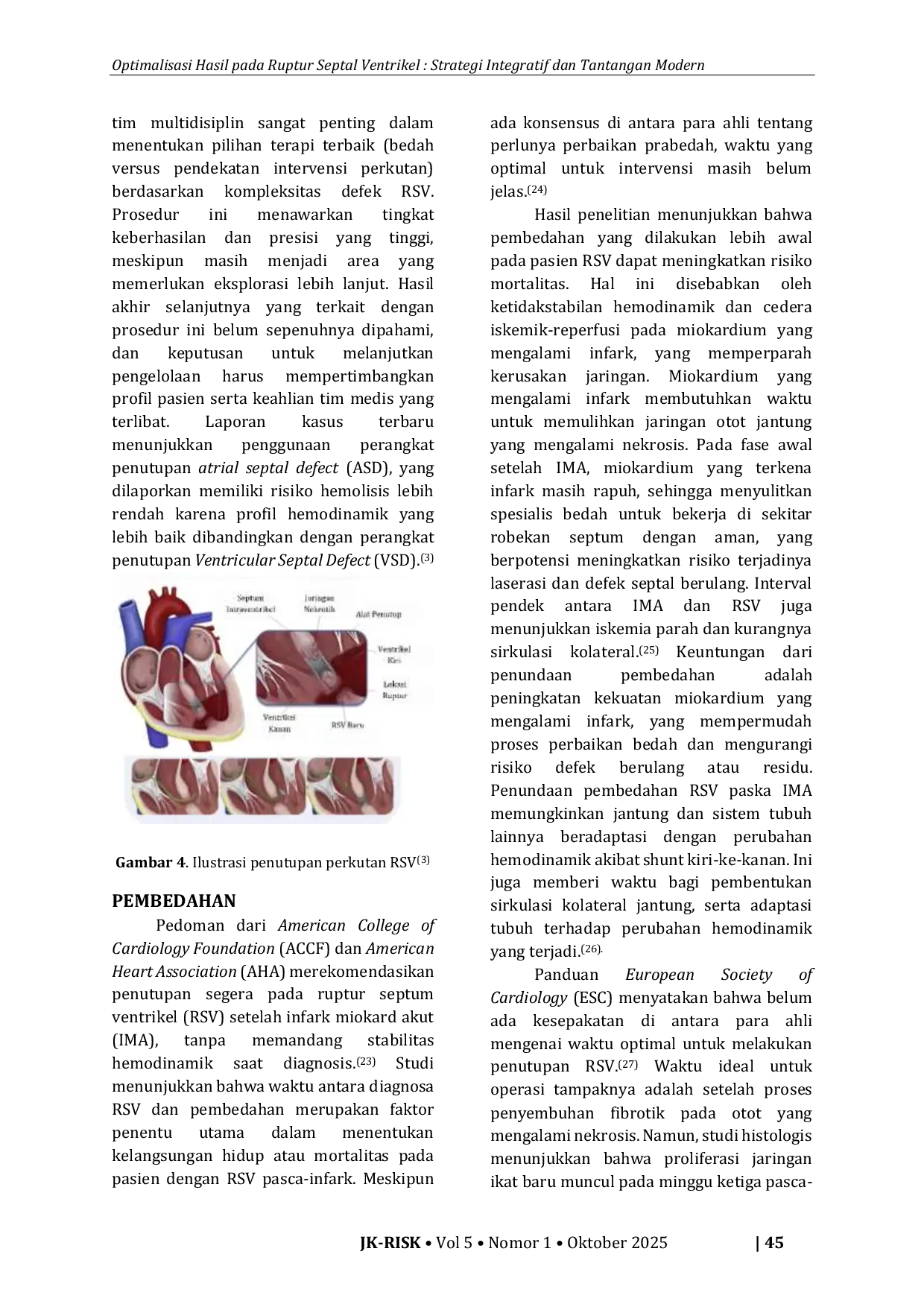

JK RISKJK RISK Sebagai alternatif, penutupan transkateter menggunakan perangkat penutup dapat digunakan baik sebagai terapi akut, subakut, maupun definitif, tergantungSebagai alternatif, penutupan transkateter menggunakan perangkat penutup dapat digunakan baik sebagai terapi akut, subakut, maupun definitif, tergantung

UBHUBH Penelitian menunjukkan bahwa komposisi 17,5/2,5/80% menghasilkan tegangan lentur tertinggi sebesar 70,5 MPa dan kekerasan maksimum 99,1. Komposisi danPenelitian menunjukkan bahwa komposisi 17,5/2,5/80% menghasilkan tegangan lentur tertinggi sebesar 70,5 MPa dan kekerasan maksimum 99,1. Komposisi dan

UNUSAUNUSA ) menjadi kandidat sumber pewarna alternatif karena kandungan pigmen antosianinnya yang tinggi. Tujuan penelitian ini adalah menentukan ekstrak kulit ubi) menjadi kandidat sumber pewarna alternatif karena kandungan pigmen antosianinnya yang tinggi. Tujuan penelitian ini adalah menentukan ekstrak kulit ubi