JRTPPIJRTPPI

Jurnal Riset Teknologi Pencegahan Pencemaran IndustriJurnal Riset Teknologi Pencegahan Pencemaran IndustriGreen diesel is a mixture of straight-chain and branched-chain alkanes, typically mostly 15 to 18 carbon atoms per molecule (C15 to C18) extracted from the hydrotreating process of vegetable oils. In this study, a catalyst of Nickel (Ni) promoted Zinc (Zn) supported by Alumina (Al2O3) was used. The catalyst was made by varying the use of and without the Zn promoter in the catalyst. Catalyst tested for Scanning Electron Microscope characterization. For the 60Ni/Al2O3 catalyst, the total area was 51,575.51 m2/gr, while for the 15Ni-45Zn/Al2O3 catalyst, the total area was 20.577,55 m2/gr. Furthermore, a performance test of the catalyst was also carried out using a green diesel reactor with a temperature of 400°C and a pressure of 20 bar, the percentage yield on the 60Ni/Al2O3 catalyst was 25.73% while the 30Ni-30Zn/Al2O3 catalyst was 23.60%. The 60Ni/Al2O3 catalyst has the following properties: physical properties such as density, viscosity, flash point, cetane number, and acid number of 765.17 ± 0.249 kg/m3, 3.55 ± 0.076 mm2/s, 60.73 ± 0.170°C, 88.10 ± 0.648 CN, and 0.33 ± 0.76 mgKOH/g, respectively. The 15Ni-45Zn/Al2O3 catalyst has the following properties: physical properties such as density of 766.77 ± 0.679 kg/m3, viscosity of 66.13 ± 0.249 mm2/s, flash point of 2.92 ± 0.011°C, cetane number of 82.33 ± 0.386, and acid number of 82.33 ± 0.386 mgKOH/g.

This study demonstrates that the 60Ni/γ-Al2O3 and 15Ni-45Zn/γ-Al2O3 catalysts are superior to the Ni-Mo/γ-Al2O3 catalysts in terms of green diesel criteria.The variations in catalyst materials impact the final products quality, with the 60Ni/γ-Al2O3 catalyst yielding a higher yield of 25.The results highlight the importance of optimizing catalyst composition to achieve desired product properties and engine performance.

Penelitian lebih lanjut perlu dilakukan untuk menguji efektivitas katalis Ni/γ-Al2O3 yang dipromosikan dengan logam transisi lain selain seng, seperti ruthenium atau platinum, untuk meningkatkan aktivitas katalitik dan selektivitas terhadap produk green diesel. Selain itu, studi komprehensif mengenai pengaruh ukuran partikel katalis dan metode preparasi terhadap kinerja katalis perlu dilakukan untuk mengoptimalkan struktur katalis dan memaksimalkan luas permukaan aktif. Terakhir, penelitian mengenai penggunaan reaktor yang berbeda, seperti reaktor unggun tetap atau reaktor fluidized bed, dapat dilakukan untuk meningkatkan efisiensi proses hydrotreating dan mengurangi biaya produksi green diesel, serta mengeksplorasi potensi integrasi proses hydrotreating dengan proses lain seperti transesterifikasi untuk menghasilkan biofuel yang lebih beragam dan berkelanjutan.

- CHEESA : Chemical Engineering Research Articles. warning trying access array offset value type null var... e-journal.unipma.ac.id/index.php/cheesa/article/view/10348CHEESA Chemical Engineering Research Articles warning trying access array offset value type null var e journal unipma ac index php cheesa article view 10348

- KONVERSI MINYAK JELANTAH MENJADI GREEN DIESEL DENGAN PROSES HYDROTREATING MENGGUNAKAN KATALIS NiMo/ ?-Al2O3... doi.org/10.52436/1.jpti.116KONVERSI MINYAK JELANTAH MENJADI GREEN DIESEL DENGAN PROSES HYDROTREATING MENGGUNAKAN KATALIS NiMo Al2O3 doi 10 52436 1 jpti 116

| File size | 891.44 KB |

| Pages | 9 |

| Short Link | https://juris.id/p-2UB |

| Lookup Links | Google ScholarGoogle Scholar, Semantic ScholarSemantic Scholar, CORE.ac.ukCORE.ac.uk, WorldcatWorldcat, ZenodoZenodo, Research GateResearch Gate, Academia.eduAcademia.edu, OpenAlexOpenAlex, Hollis HarvardHollis Harvard |

| DMCA | Report |

Related /

MULIADARMAMULIADARMA Indofood CBP Sukses Makmur Tbk periode 2016- 2022. Teknik pengumpulan data yang di gunakan adalah studi pustaka dan dokumentasi. Metode analisis data yangIndofood CBP Sukses Makmur Tbk periode 2016- 2022. Teknik pengumpulan data yang di gunakan adalah studi pustaka dan dokumentasi. Metode analisis data yang

UIGMUIGM Program ini bertujuan untuk mengatasi permasalahan tersebut melalui serangkaian kegiatan yang meliputi sosialisasi, bantuan peralatan, pelatihan, dan penerapanProgram ini bertujuan untuk mengatasi permasalahan tersebut melalui serangkaian kegiatan yang meliputi sosialisasi, bantuan peralatan, pelatihan, dan penerapan

UIGMUIGM Pelatihan interaktif berdampak positif pada peningkatan kesadaran, namun diperlukan penguatan keterampilan praktis untuk pengelolaan WCO serta edukasiPelatihan interaktif berdampak positif pada peningkatan kesadaran, namun diperlukan penguatan keterampilan praktis untuk pengelolaan WCO serta edukasi

UIGMUIGM Respon positif mengindikasikan FunMath dapat menjadi alat pembelajaran alternatif yang berharga, meningkatkan kualitas pendidikan matematika dan memfasilitasiRespon positif mengindikasikan FunMath dapat menjadi alat pembelajaran alternatif yang berharga, meningkatkan kualitas pendidikan matematika dan memfasilitasi

UIGMUIGM Kegiatan ini mampu meningkatkan pengetahuan pegawai PUPR Sumatera Utara rata-rata sebesar 35% dan diharapkan dapat membawa perubahan yang baik pada peneranganKegiatan ini mampu meningkatkan pengetahuan pegawai PUPR Sumatera Utara rata-rata sebesar 35% dan diharapkan dapat membawa perubahan yang baik pada penerangan

UIGMUIGM Untuk mengatasi permasalahan tersebut, tim PkM mengembangkan aplikasi FunMath berbasis Android sebagai media pembelajaran matematika yang interaktif, menarik,Untuk mengatasi permasalahan tersebut, tim PkM mengembangkan aplikasi FunMath berbasis Android sebagai media pembelajaran matematika yang interaktif, menarik,

UIGMUIGM Program intervensi 1000 Hari Pertama Kehidupan (HPK) di Desa Senoni, Kecamatan Sebulu, Kabupaten Kutai Kartanegara telah berhasil dilaksanakan melaluiProgram intervensi 1000 Hari Pertama Kehidupan (HPK) di Desa Senoni, Kecamatan Sebulu, Kabupaten Kutai Kartanegara telah berhasil dilaksanakan melalui

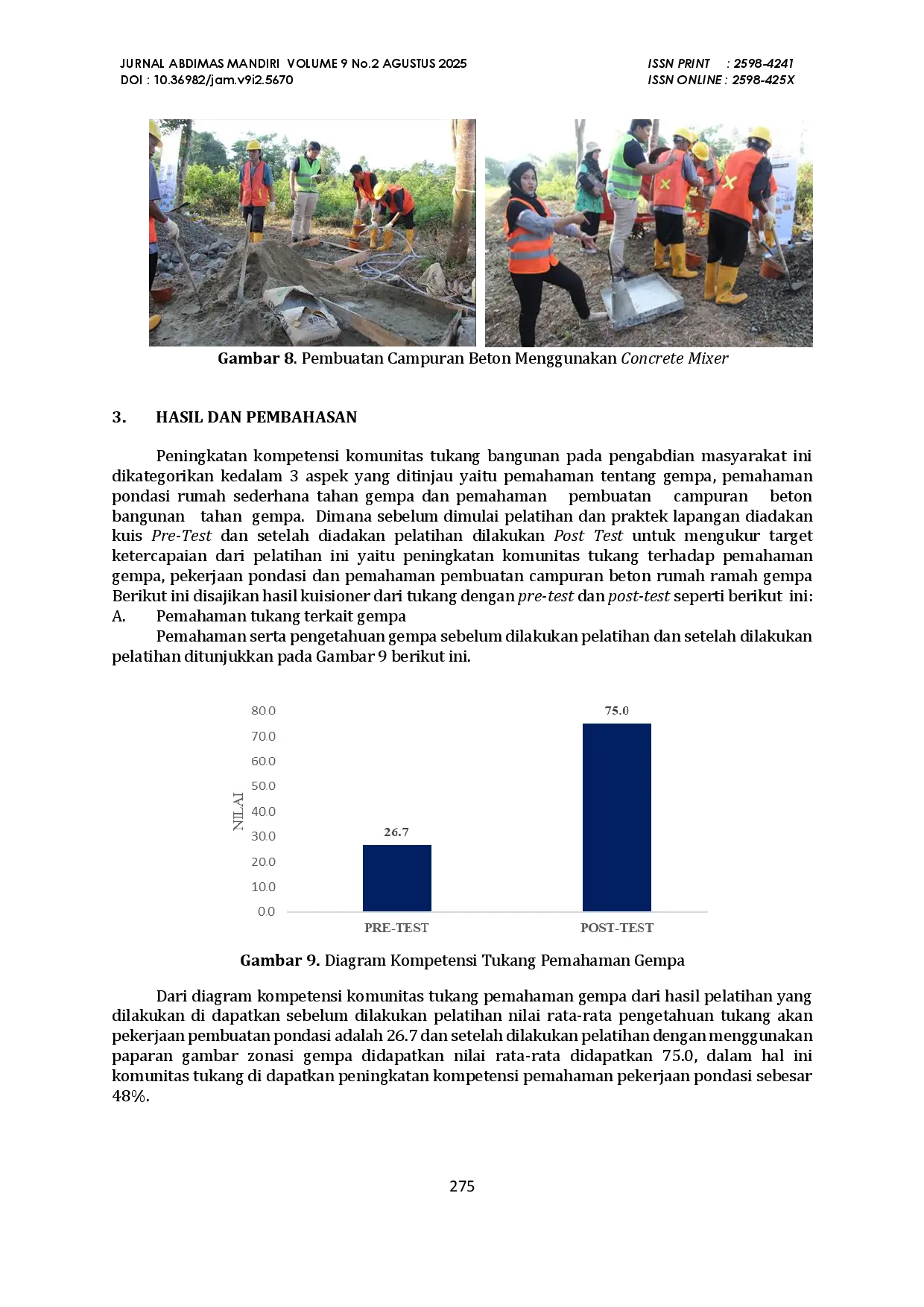

UIGMUIGM Komunitas Sinergi Tukang yang berdomisili di Kecamatan Menes dan sekitarnya, Kabupaten Pandeglang, Banten, yang berada di bawah arahan Mitra PT. TunasKomunitas Sinergi Tukang yang berdomisili di Kecamatan Menes dan sekitarnya, Kabupaten Pandeglang, Banten, yang berada di bawah arahan Mitra PT. Tunas

Useful /

UIGMUIGM Kegiatan pengabdian masyarakat berupa pelayanan kesehatan kulit di Desa Banyu Urip berhasil dilaksanakan dengan baik dan mendapat respons positif, yangKegiatan pengabdian masyarakat berupa pelayanan kesehatan kulit di Desa Banyu Urip berhasil dilaksanakan dengan baik dan mendapat respons positif, yang

UIGMUIGM Pelatihan pengolahan data asuhan kebidanan berbasis data mining dengan RapidMiner bagi mahasiswa tingkat akhir bertujuan untuk meningkatkan keterampilanPelatihan pengolahan data asuhan kebidanan berbasis data mining dengan RapidMiner bagi mahasiswa tingkat akhir bertujuan untuk meningkatkan keterampilan

JRTPPIJRTPPI Komposisi arang aktif serbuk tempurung kelapa 15% memberikan penurunan kadar Fe dan Mn tertinggi berturut-turut sebesar 80,83% dan 18,75%. Penurunan iniKomposisi arang aktif serbuk tempurung kelapa 15% memberikan penurunan kadar Fe dan Mn tertinggi berturut-turut sebesar 80,83% dan 18,75%. Penurunan ini

JRTPPIJRTPPI Koagulan alami memenuhi standar kualitas karet meskipun memiliki kandungan abu, kotoran, dan bahan mudah menguap lebih tinggi. Hasil penelitian ini memberikanKoagulan alami memenuhi standar kualitas karet meskipun memiliki kandungan abu, kotoran, dan bahan mudah menguap lebih tinggi. Hasil penelitian ini memberikan