KJPUPIKJPUPI

Indonesian Journal of Science and TechnologyIndonesian Journal of Science and TechnologyPinch analysis has been known as one of the tools for smart energy management. This technique has successfully been applied in more than three decades in various industries. Here, the purpose of this study was to describe how to use pinch analysis for . In a revamping project of a chemical plant, the pinch analysis is applied to find a better design. The analysis reveals that the revamped case can be further improved to achieve more energy saving. This is done by applying one of the golden rules in pinch analysis, which is not to transfer heat across the pinch. The proposed solution is rather simple and straightforward, leading to only few months of payback period and 165 k€ per annual saving.

Pinch analysis successfully improved the design of a revamped chemical plant.The proposed modification, involving minor pipe rerouting and additional heat exchanger area, resulted in significant energy savings.The implementation boasts a rapid payback period of only three months and an annual saving of 165 k€.

Penelitian lebih lanjut dapat dilakukan untuk menguji penerapan analisis pinch pada pabrik kimia dengan proses yang lebih kompleks dan beragam, termasuk mempertimbangkan integrasi dengan sumber energi terbarukan. Selain itu, studi komparatif dapat dilakukan untuk membandingkan efektivitas analisis pinch dengan metode optimasi jaringan penukar panas lainnya, seperti algoritma genetika atau pembelajaran mesin, untuk mengidentifikasi pendekatan yang paling efisien dan hemat biaya. Terakhir, penelitian dapat difokuskan pada pengembangan perangkat lunak atau alat bantu komputasi yang lebih canggih dan mudah digunakan untuk memfasilitasi penerapan analisis pinch oleh para insinyur dan praktisi industri, sehingga mempercepat adopsi teknologi ini dan mendorong efisiensi energi yang lebih besar.

| File size | 1.16 MB |

| Pages | 10 |

| DMCA | ReportReport |

Related /

KOMPETIFKOMPETIF Banyak penelitian telah menerapkan gaya koping untuk mengaitkan stres dengan kesejahteraan subjektif. Namun, dalam penelitian ini peneliti tertarik untukBanyak penelitian telah menerapkan gaya koping untuk mengaitkan stres dengan kesejahteraan subjektif. Namun, dalam penelitian ini peneliti tertarik untuk

KOMPETIFKOMPETIF Meskipun ada penurunan laba bersih selama pandemi, kinerja kesehatan bank BRI tetap tergolong sangat sehat sesuai dengan penilaian menggunakan metode RiskMeskipun ada penurunan laba bersih selama pandemi, kinerja kesehatan bank BRI tetap tergolong sangat sehat sesuai dengan penilaian menggunakan metode Risk

KOMPETIFKOMPETIF This study aims to determine the relationship between leadership and competence on employee performance through motivation as an intervening variable atThis study aims to determine the relationship between leadership and competence on employee performance through motivation as an intervening variable at

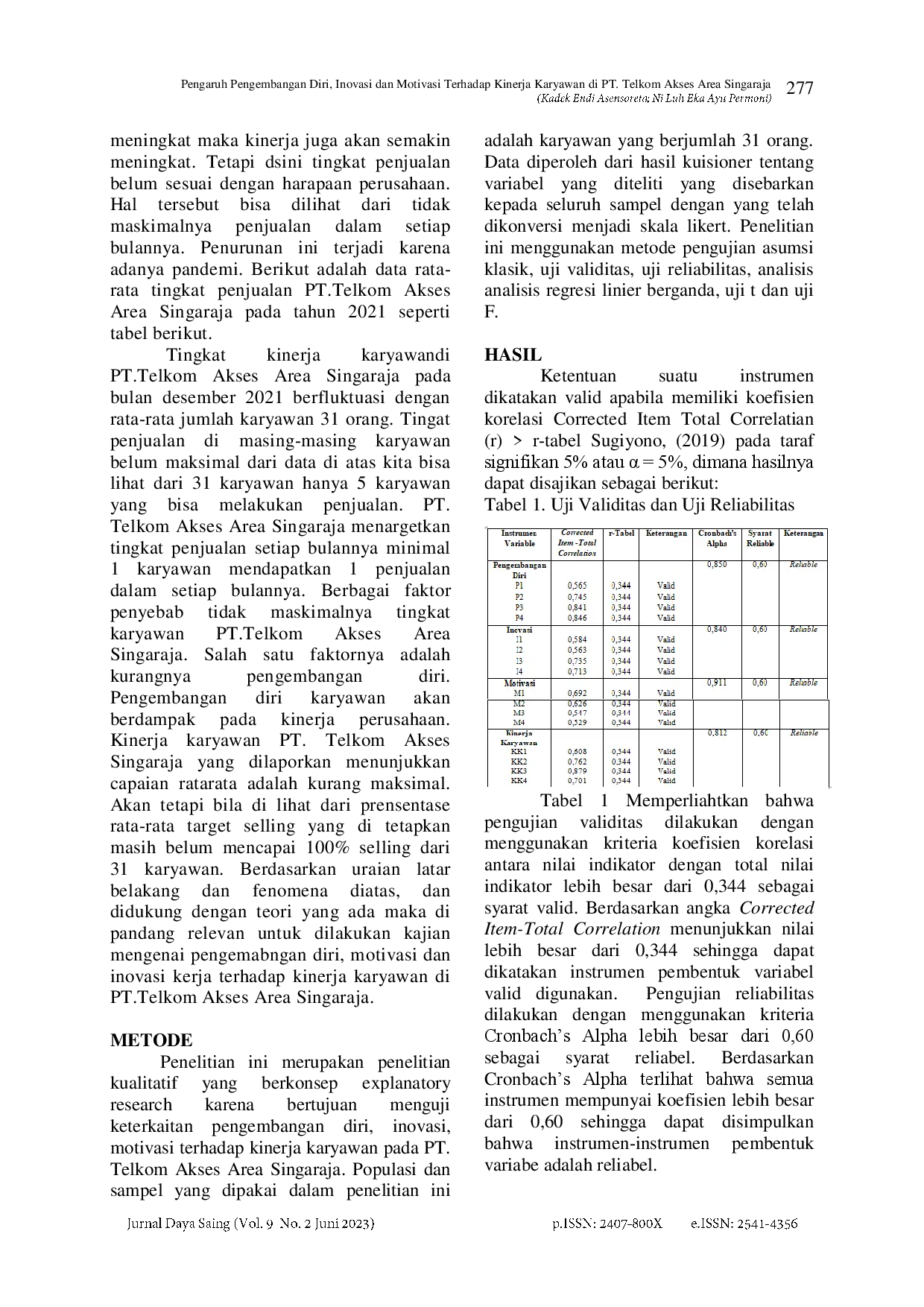

KOMPETIFKOMPETIF Pengembangan diri berkontribusi sebesar 25,3%, inovasi sebesar 34,5%, dan motivasi sebesar 16,7% terhadap kinerja karyawan. Secara keseluruhan, ketigaPengembangan diri berkontribusi sebesar 25,3%, inovasi sebesar 34,5%, dan motivasi sebesar 16,7% terhadap kinerja karyawan. Secara keseluruhan, ketiga

Useful /

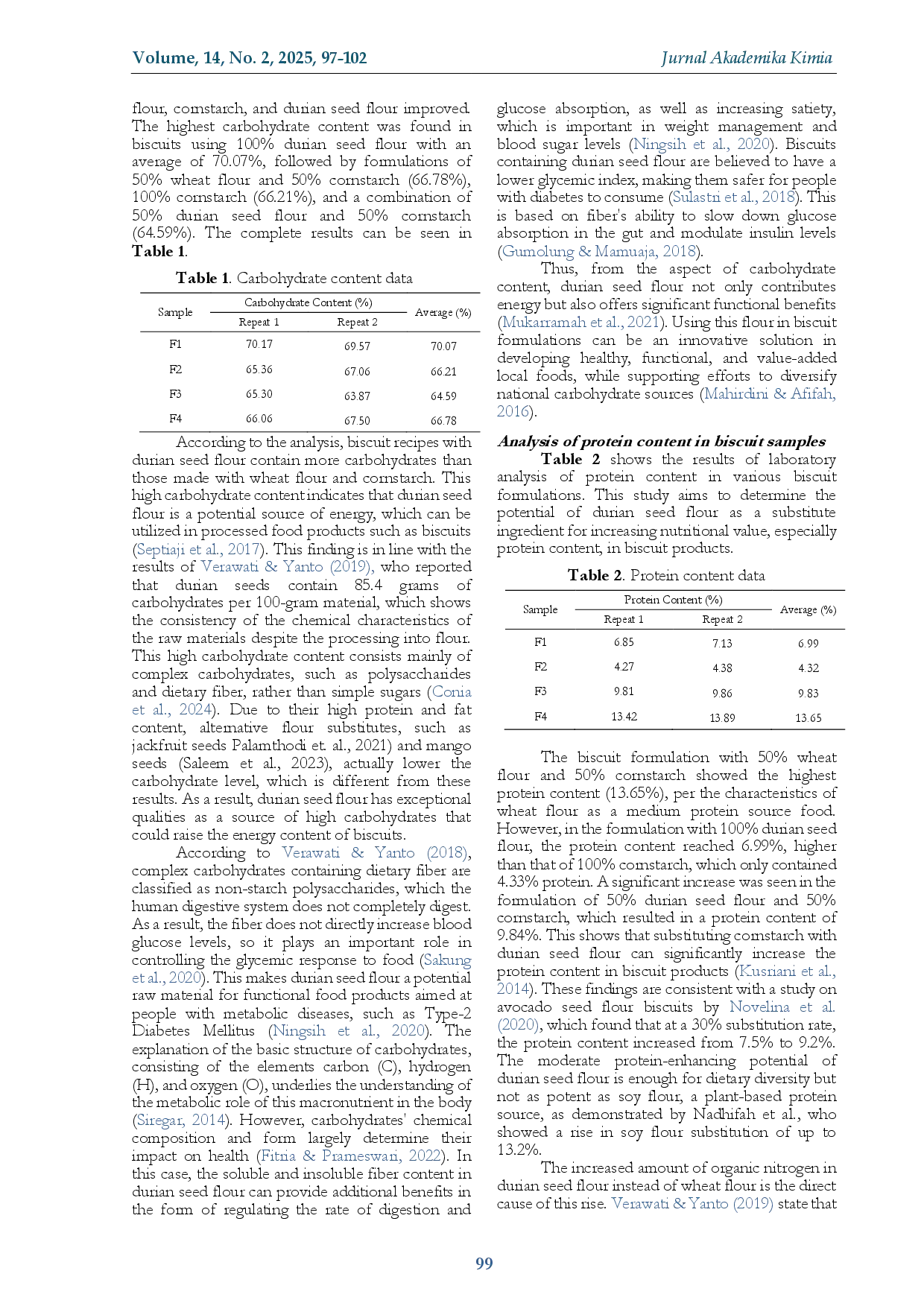

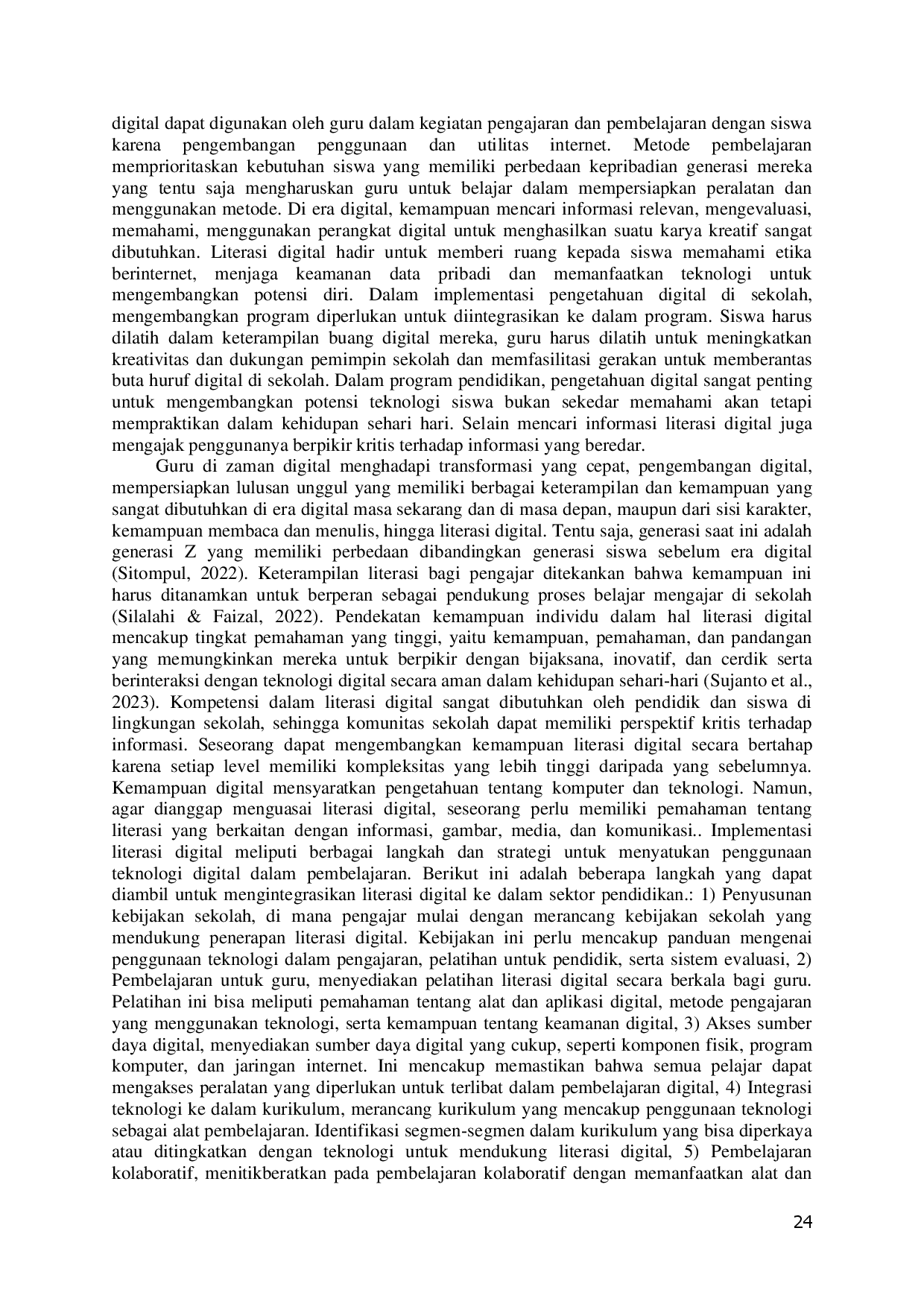

JURNALFKIPUNTADJURNALFKIPUNTAD Secara keseluruhan, formulasi campuran 50% tepung biji durian dan 50% tepung tapioka dapat menjadi alternatif untuk meningkatkan nilai gizi biskuit, mengurangiSecara keseluruhan, formulasi campuran 50% tepung biji durian dan 50% tepung tapioka dapat menjadi alternatif untuk meningkatkan nilai gizi biskuit, mengurangi

OJSOJS Mengembangkan literasi digital merupakan keterampilan penting yang harus dikembangkan sekolah untuk membekali siswa menghadapi tantangan era digital. LiterasiMengembangkan literasi digital merupakan keterampilan penting yang harus dikembangkan sekolah untuk membekali siswa menghadapi tantangan era digital. Literasi

OJSOJS Hasil penelitian menunjukkan bahwa model pembelajaran berbasis digital memiliki pengaruh signifikan terhadap peningkatan kemampuan membaca, mencakup aspekHasil penelitian menunjukkan bahwa model pembelajaran berbasis digital memiliki pengaruh signifikan terhadap peningkatan kemampuan membaca, mencakup aspek

UNDIKSHAUNDIKSHA Simpulan penelitian menunjukkan hubungan antara dukungan sosial, beban belajar, kecerdasan emosional, kejenuhan, dan prestasi belajar matematika salingSimpulan penelitian menunjukkan hubungan antara dukungan sosial, beban belajar, kecerdasan emosional, kejenuhan, dan prestasi belajar matematika saling