UMJ PremiumUMJ Premium

International Conference on Engineering, Applied Sciences and TechnologyInternational Conference on Engineering, Applied Sciences and TechnologyHeavy equipment plays a crucial role in the mining industry, as mining operations are large-scale undertakings that require efficient machinery to support productivity and ensure operational success. The Komatsu D85ESS-2 dozer is one of the heavy machines employed by PT. Andhifa Kharisma Borneo Pratama (AKBP) at the PT. Prolindo Cipta Nusantara (PCNS) site in coal mining operations. However, due to several factors, this unit has experienced an engine low power issue, impacting its performance. This report addresses the root causes of this problem and proposes solutions to prevent recurrence. This study uses an observational approach aimed at identifying and analyzing the factors causing the low power issue. Findings indicate that engine low power was caused by sediment buildup in the fuel filter, which restricted fuel flow to the nozzle, leading to reduced fuel injection.

The inspection results revealed that several components in the fuel system, particularly the filters and strainers, were contaminated with debris.This buildup of impurities obstructed the flow of fuel through the system, leading to a decrease in fuel supply to the nozzles during injection.The restricted fuel flow caused the engine to experience low power, as the reduced fuel delivery impacted the combustion process.As an initial step, the fuel filter was cleaned to temporarily restore fuel flow.however, replacing the fuel filter entirely would be the most effective solution to prevent recurring issues and optimize engine performance.

Berdasarkan temuan studi ini, beberapa arah penelitian lanjutan dapat dieksplorasi untuk meningkatkan pemahaman dan penanganan masalah daya rendah pada mesin Komatsu D85ESS-2. Pertama, penelitian lebih lanjut dapat difokuskan pada pengembangan sistem pemantauan real-time untuk mendeteksi secara dini adanya penumpukan sedimen dalam filter bahan bakar, sehingga tindakan pencegahan dapat diambil sebelum terjadi penurunan kinerja mesin. Kedua, studi komparatif dapat dilakukan untuk mengevaluasi efektivitas berbagai jenis filter bahan bakar dalam mencegah penumpukan sedimen di lingkungan operasional yang berbeda, mempertimbangkan faktor-faktor seperti kualitas bahan bakar dan kondisi lingkungan. Ketiga, penelitian dapat dilakukan untuk menginvestigasi dampak penggunaan aditif bahan bakar terhadap pembentukan sedimen dan kinerja mesin secara keseluruhan, dengan tujuan mengidentifikasi formulasi aditif yang optimal untuk mencegah masalah daya rendah dan memperpanjang umur pakai komponen mesin. Penelitian-penelitian ini diharapkan dapat memberikan kontribusi signifikan dalam meningkatkan keandalan dan efisiensi operasional mesin berat di industri pertambangan.

- The Development of Exhaust Fan Housing With Ceiling Mounting For High Rise Buildings by Using DFMA |... doi.org/10.37385/jaets.v4i2.1675The Development of Exhaust Fan Housing With Ceiling Mounting For High Rise Buildings by Using DFMA doi 10 37385 jaets v4i2 1675

- Numerical Study on the Influence of Torque Performance Caused by Deflectors on Darrieus Wind Turbines... doi.org/10.37934/arfmts.118.2.1323Numerical Study on the Influence of Torque Performance Caused by Deflectors on Darrieus Wind Turbines doi 10 37934 arfmts 118 2 1323

- The Impact of Modified Atmosphere Storage Treatment on Glucose Levels and Mass Transfer Coefficients:... journal.yrpipku.com/index.php/jaets/article/view/3481The Impact of Modified Atmosphere Storage Treatment on Glucose Levels and Mass Transfer Coefficients journal yrpipku index php jaets article view 3481

- An Electrorheological Fluid Actuator for Rehabilitation Robotics | IEEE Journals & Magazine | IEEE... doi.org/10.1109/TMECH.2018.2869126An Electrorheological Fluid Actuator for Rehabilitation Robotics IEEE Journals Magazine IEEE doi 10 1109 TMECH 2018 2869126

| File size | 589.22 KB |

| Pages | 7 |

| DMCA | Report |

Related /

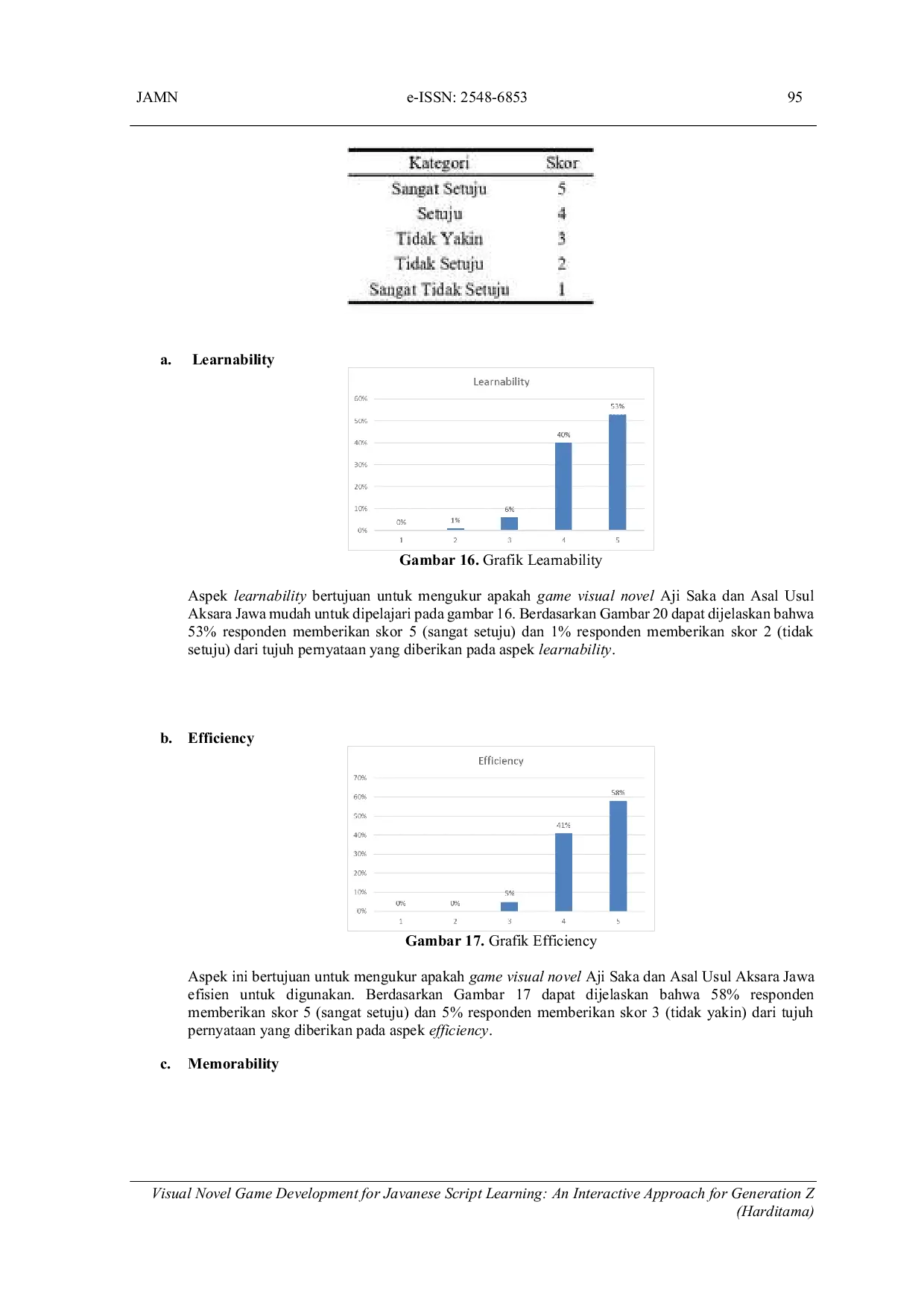

POLIBATAMPOLIBATAM Usability evaluation across five aspects (Learnability, Efficiency, Memorability, Error, and Satisfaction) yielded an average score of 4. 538/5, reflectingUsability evaluation across five aspects (Learnability, Efficiency, Memorability, Error, and Satisfaction) yielded an average score of 4. 538/5, reflecting

PENELITIPENELITI The purpose of this research is to improve the application and influence of information technology on tourism village marketing strategy. The use of descriptiveThe purpose of this research is to improve the application and influence of information technology on tourism village marketing strategy. The use of descriptive

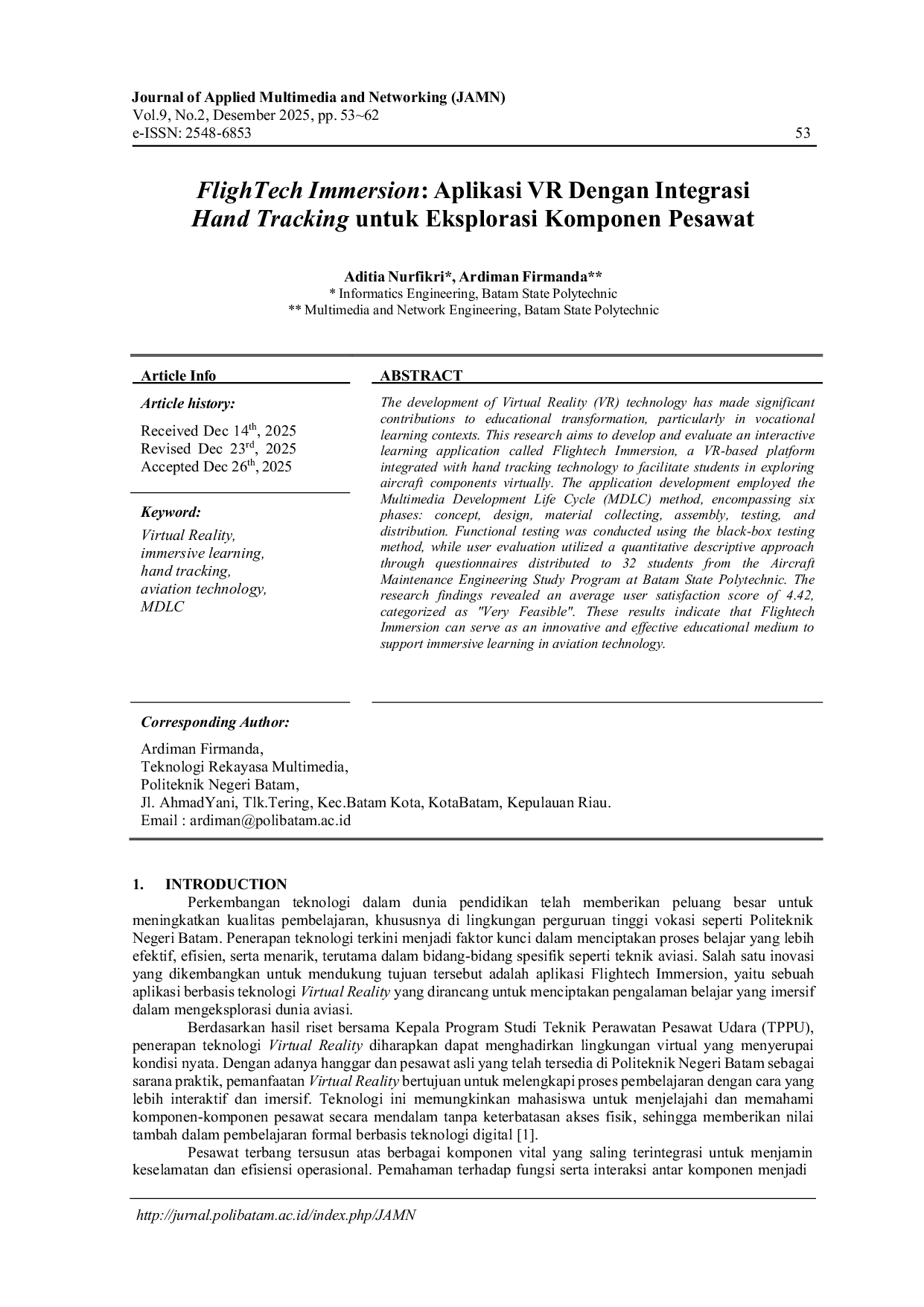

POLIBATAMPOLIBATAM Pengembangan teknologi Virtual Reality (VR) telah memberikan kontribusi signifikan terhadap transformasi pendidikan, terutama dalam konteks pembelajaranPengembangan teknologi Virtual Reality (VR) telah memberikan kontribusi signifikan terhadap transformasi pendidikan, terutama dalam konteks pembelajaran

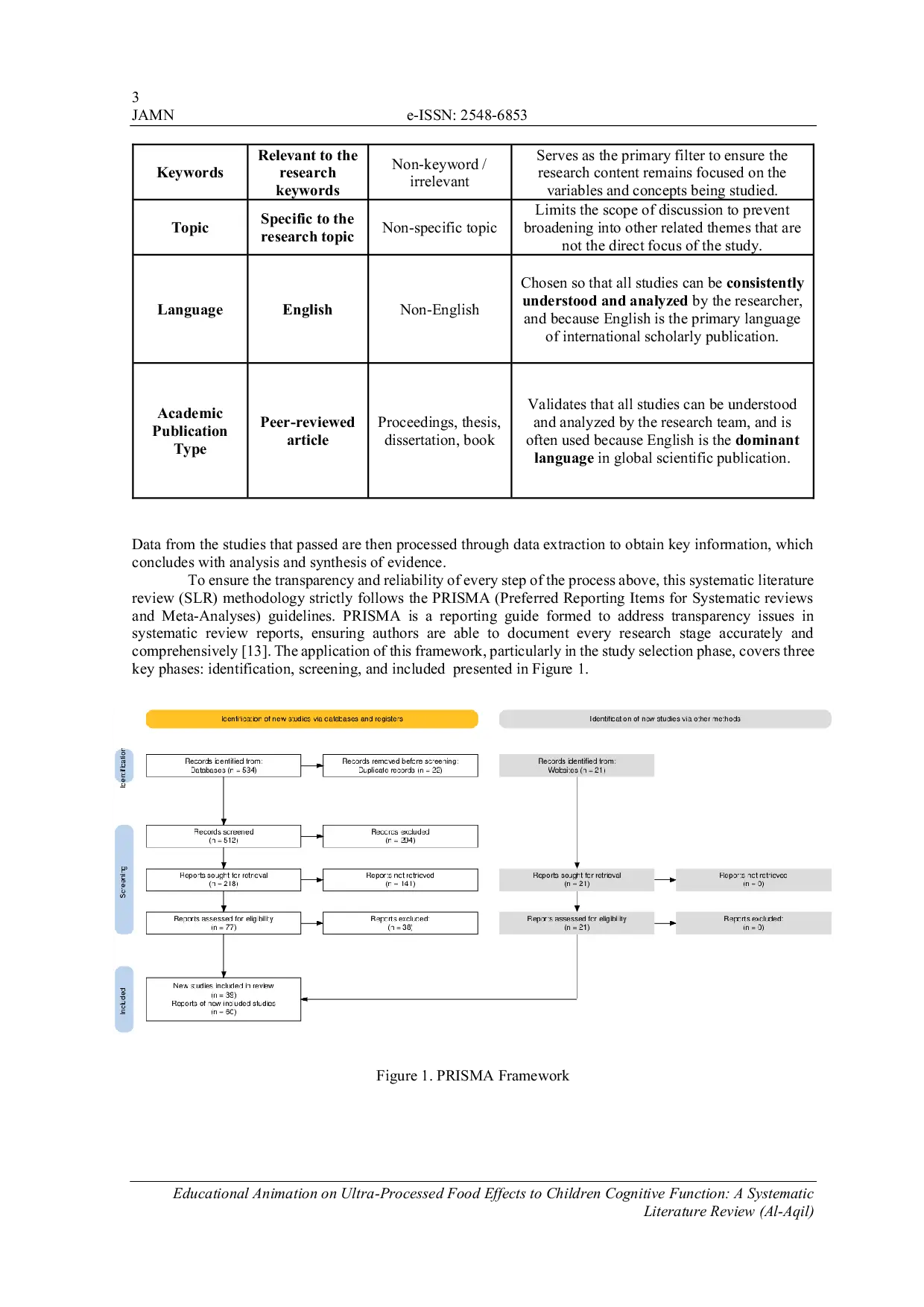

POLIBATAMPOLIBATAM Konsumsi makanan ultra-proses (UPF) menimbulkan risiko serius terhadap fungsi kognitif anak selama masa perkembangan otak yang kritis. Media pendidikanKonsumsi makanan ultra-proses (UPF) menimbulkan risiko serius terhadap fungsi kognitif anak selama masa perkembangan otak yang kritis. Media pendidikan

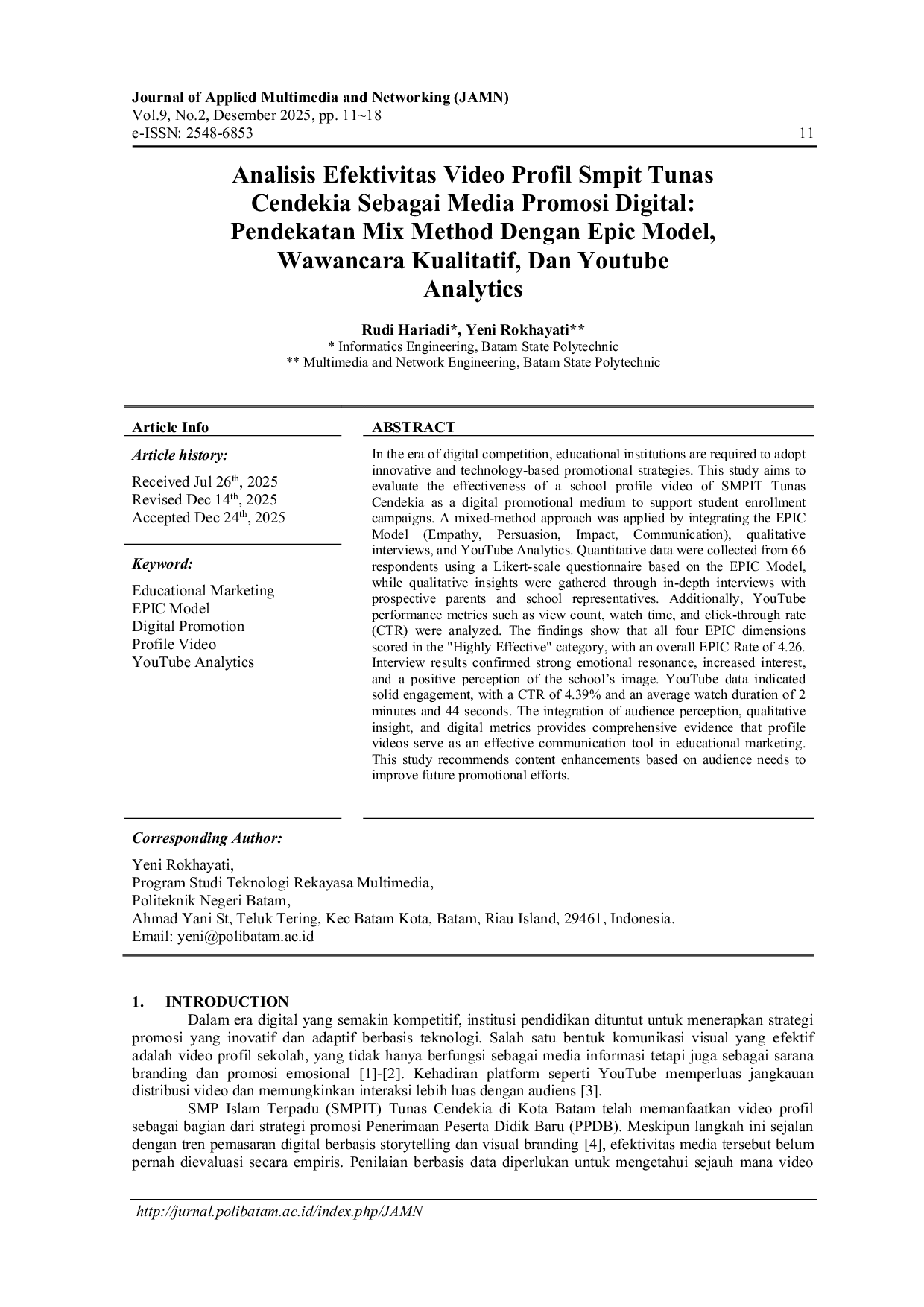

POLIBATAMPOLIBATAM A mixed-method approach was applied by integrating the EPIC Model (Empathy, Persuasion, Impact, Communication), qualitative interviews, and YouTube Analytics.A mixed-method approach was applied by integrating the EPIC Model (Empathy, Persuasion, Impact, Communication), qualitative interviews, and YouTube Analytics.

UMJ PremiumUMJ Premium The study demonstrates that gamified solutions can effectively address contemporary urban tourism challenges, fostering responsible tourism behaviors andThe study demonstrates that gamified solutions can effectively address contemporary urban tourism challenges, fostering responsible tourism behaviors and

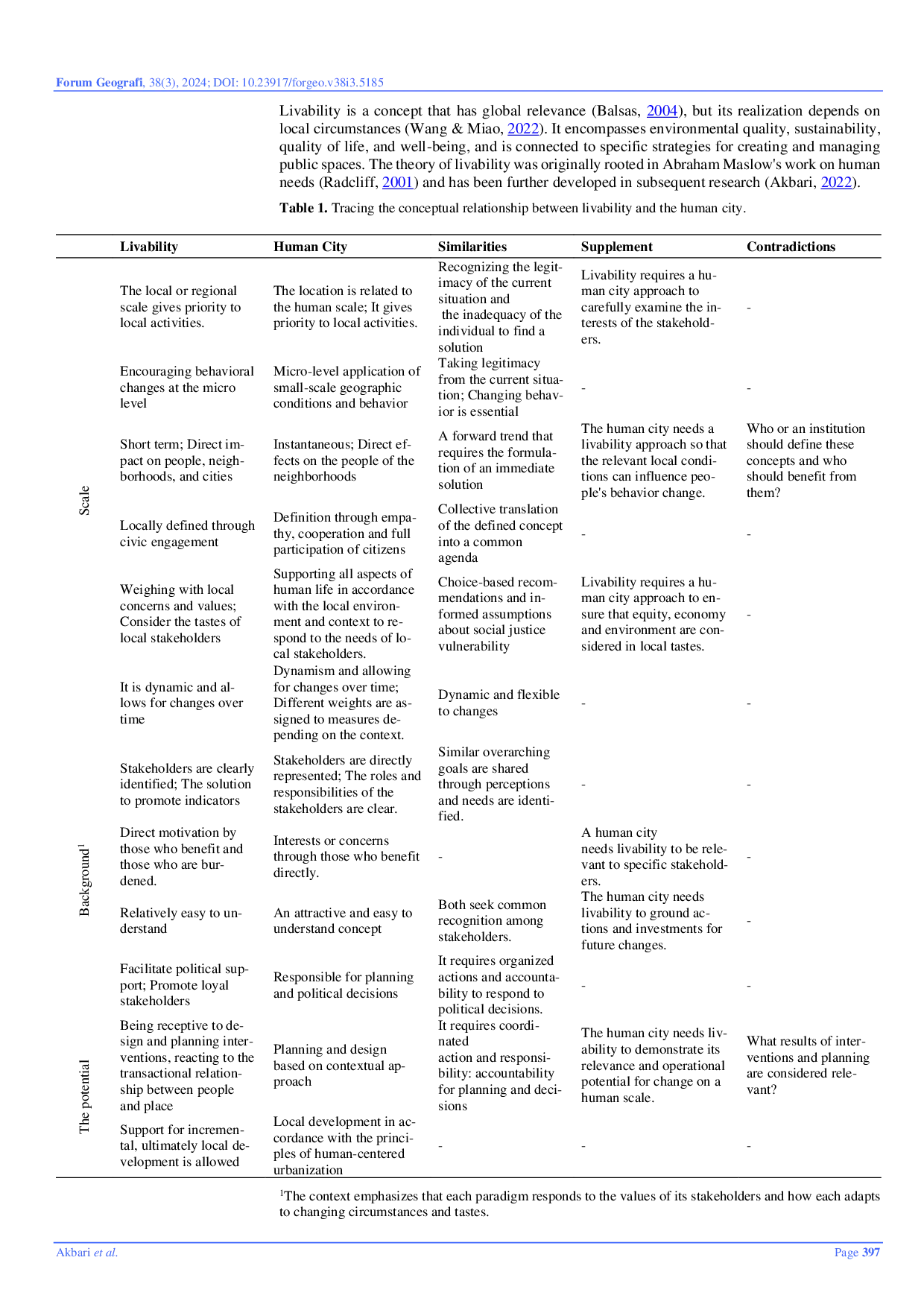

UMSUMS Kualitas hidup perkotaan adalah ukuran penting dari pengembangan perkotaan yang berkelanjutan. Studi ini bertujuan untuk menganalisis faktor-faktor yangKualitas hidup perkotaan adalah ukuran penting dari pengembangan perkotaan yang berkelanjutan. Studi ini bertujuan untuk menganalisis faktor-faktor yang

UMSUMS Menurut para ilmuwan yang mempelajari perubahan iklim global, Asia Tengah rentan terhadap peningkatan suhu global. Namun, penelitian yang bertujuan menganalisisMenurut para ilmuwan yang mempelajari perubahan iklim global, Asia Tengah rentan terhadap peningkatan suhu global. Namun, penelitian yang bertujuan menganalisis

Useful /

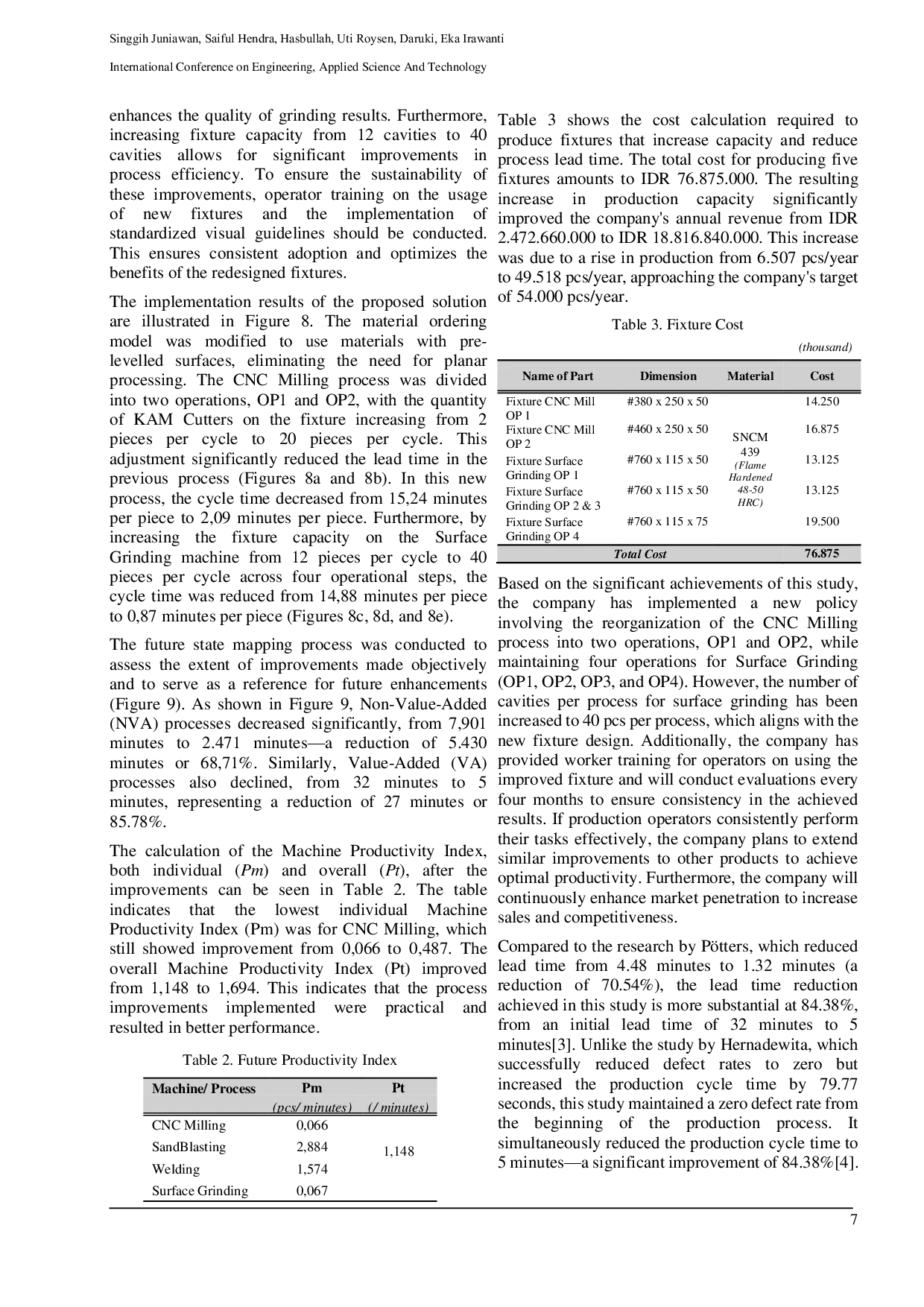

UMJ PremiumUMJ Premium Penelitian ini bertujuan meningkatkan kapasitas produksi dengan memperbaiki lead‑time pada lantai produksi. Alat Lean Manufacturing yang digunakan meliputiPenelitian ini bertujuan meningkatkan kapasitas produksi dengan memperbaiki lead‑time pada lantai produksi. Alat Lean Manufacturing yang digunakan meliputi

UMJ PremiumUMJ Premium The results demonstrate that K2O impregnation successfully enhanced the stability and efficiency of the Cu-MOF catalyst for pyrolytic catalytic cracking.The results demonstrate that K2O impregnation successfully enhanced the stability and efficiency of the Cu-MOF catalyst for pyrolytic catalytic cracking.

IAIN SUIAIN SU Kualitas pendidikan menjadi lebih bermakna ketika terdapat komunikasi yang intensif antara guru dan siswa. Komunikasi yang intensif memungkinkan guru untukKualitas pendidikan menjadi lebih bermakna ketika terdapat komunikasi yang intensif antara guru dan siswa. Komunikasi yang intensif memungkinkan guru untuk

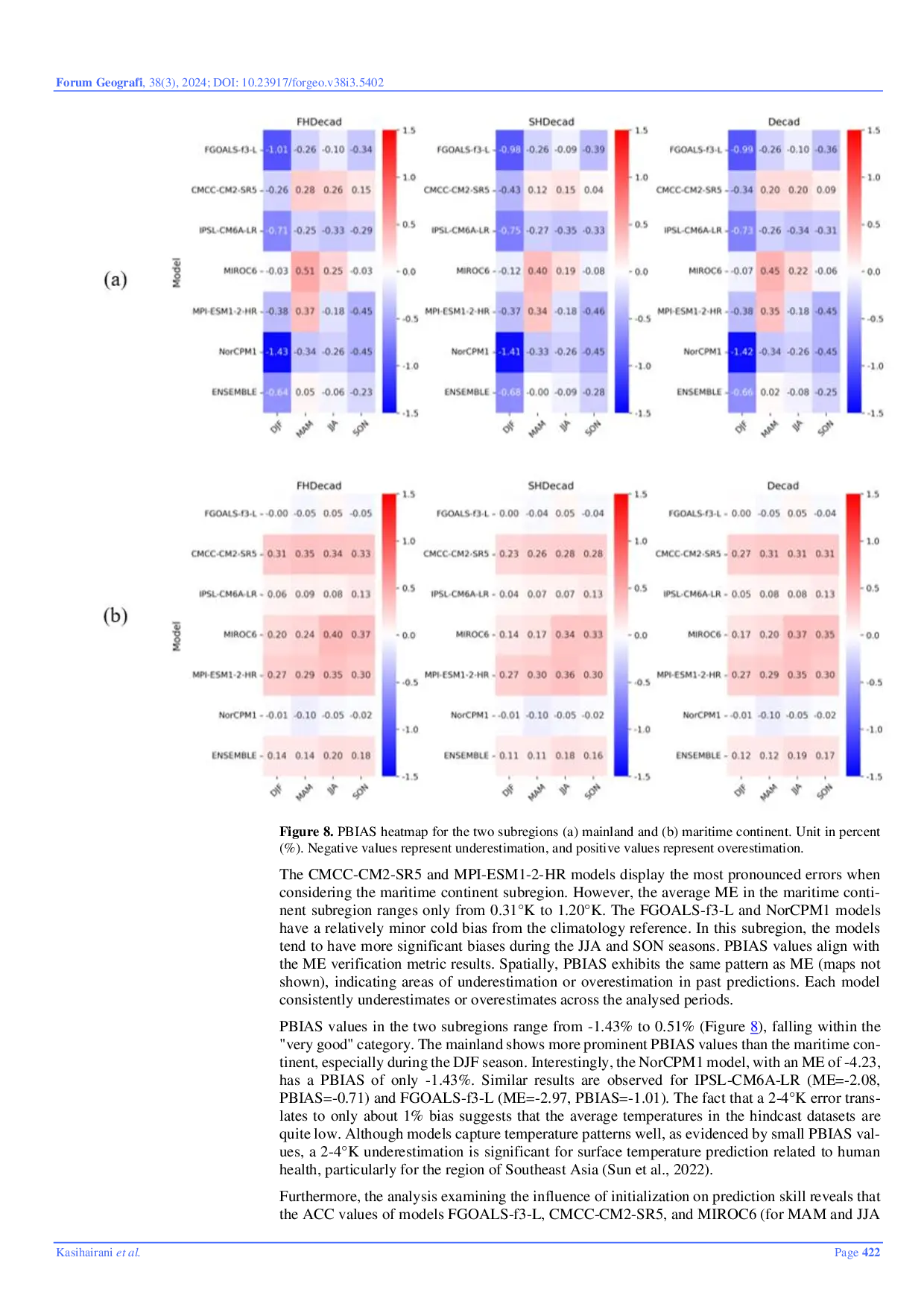

UMSUMS Nilai korelasi tertinggi terlihat pada musim September‑Oktober‑November (SON), dan model ENSEMBLE dapat meningkatkan nilai korelasi dibandingkan modelNilai korelasi tertinggi terlihat pada musim September‑Oktober‑November (SON), dan model ENSEMBLE dapat meningkatkan nilai korelasi dibandingkan model