UMBUMB

SINERGISINERGIBearing is an essential component in a mechanical rotating equipment system. It is no less important than lubrication to prevent wear, which is very important to consider in the mechanical maintenance system of rotating equipment. Bearing wear is one of the problems in wind turbines that will increase maintenance costs, shorten the turbines lifespan, and cause component or overall damage to the wind turbine. The latest technology has provided instruments for analyzing the damage of elements in a bearing according to the caused vibrations. Therefore, this study was performed on Ball Bearing Turbine Propeller to identify the dynamic characteristics of Ball Bearing with and without lubrication. The test was carried out using the Bump Test method applied in three measured parts: X, Y, and Z axes. The measuring instrument which was used was Fast Fourier Transform (FFT) Analyzer (Ono Sokki) and the data were analyzed using MATLAB. It was identified that the application of oil could reduce the amplitude and decrease the frequency. Personal frequency appearing more than once indicates the existence of global vibration modes. The frequency which only appears once in the measurement spot indicates local vibration modes. The highest frequency both after and before the application of oil was found in the Y-axis.

The study concludes that personal frequencies consistently appear in both scenarios, with and without oil application, at 4 Hz and 12 Hz, indicating the presence of global vibration modes.The addition of lubricant effectively reduces vibration amplitude at the same frequencies across all measured axes.Furthermore, the Y-axis consistently exhibits the highest frequency both before and after oil application.

Penelitian lebih lanjut dapat dilakukan untuk menginvestigasi pengaruh berbagai jenis pelumas terhadap karakteristik dinamis bantalan bola, dengan mempertimbangkan viskositas dan komposisi kimia pelumas sebagai variabel penelitian. Selain itu, studi komprehensif mengenai dampak kondisi lingkungan seperti suhu dan kelembaban terhadap kinerja bantalan bola pada turbin angin perlu dilakukan untuk memahami degradasi bantalan secara lebih mendalam. Terakhir, pengembangan model prediktif berbasis data yang menggabungkan hasil pengujian bump test dengan data operasional turbin angin dapat membantu dalam memprediksi kegagalan bantalan secara proaktif dan mengoptimalkan jadwal perawatan, sehingga meningkatkan keandalan dan efisiensi turbin angin secara keseluruhan. Penelitian-penelitian ini diharapkan dapat memberikan wawasan yang lebih baik tentang perilaku bantalan bola dalam aplikasi turbin angin dan berkontribusi pada pengembangan strategi perawatan yang lebih efektif.

- SINERGI. sinergi journal title initials issn print status sinta accredited decree frequency issues year... publikasi.mercubuana.ac.id/index.php/sinergiSINERGI sinergi journal title initials issn print status sinta accredited decree frequency issues year publikasi mercubuana ac index php sinergi

- IMPLEMENTATION OF FREQUENCY RESPONSE FUNCTION ON TAPPER BEARING MAINTENANCE | Susanto | SINERGI. frequency... doi.org/10.22441/sinergi.2019.2.006IMPLEMENTATION OF FREQUENCY RESPONSE FUNCTION ON TAPPER BEARING MAINTENANCE Susanto SINERGI frequency doi 10 22441 sinergi 2019 2 006

- Effect of Bearings on Vibration in Rotating Machinery - IOPscience. effect bearings vibration rotating... doi.org/10.1088/1757-899X/225/1/012264Effect of Bearings on Vibration in Rotating Machinery IOPscience effect bearings vibration rotating doi 10 1088 1757 899X 225 1 012264

| File size | 346.68 KB |

| Pages | 6 |

| DMCA | Report |

Related /

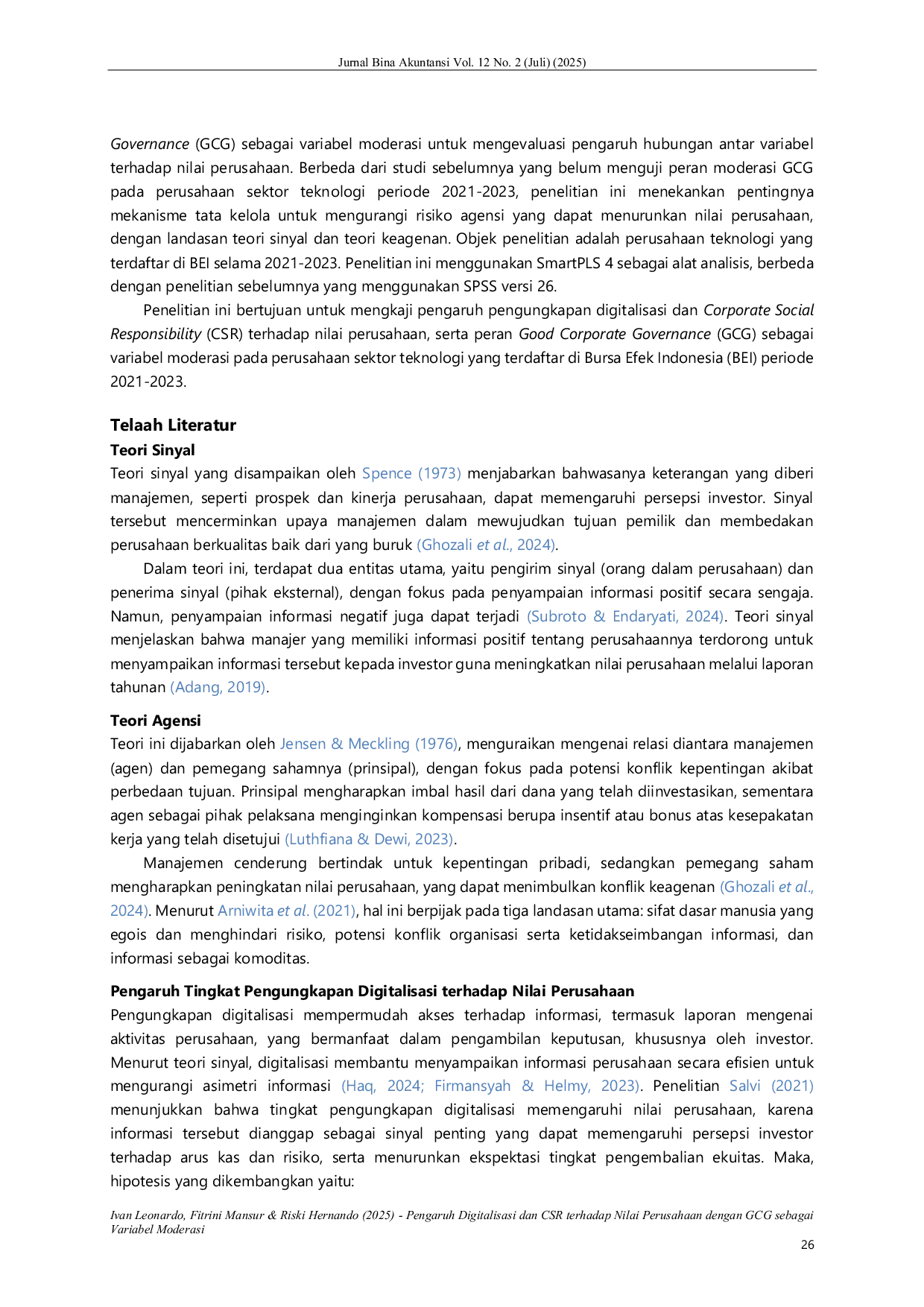

WYMWYM Penelitian ini mengisi kesenjangan literatur dengan memberikan kontribusi baru terkait pengungkapan digitalisasi yang masih jarang dieksplorasi. MerujukPenelitian ini mengisi kesenjangan literatur dengan memberikan kontribusi baru terkait pengungkapan digitalisasi yang masih jarang dieksplorasi. Merujuk

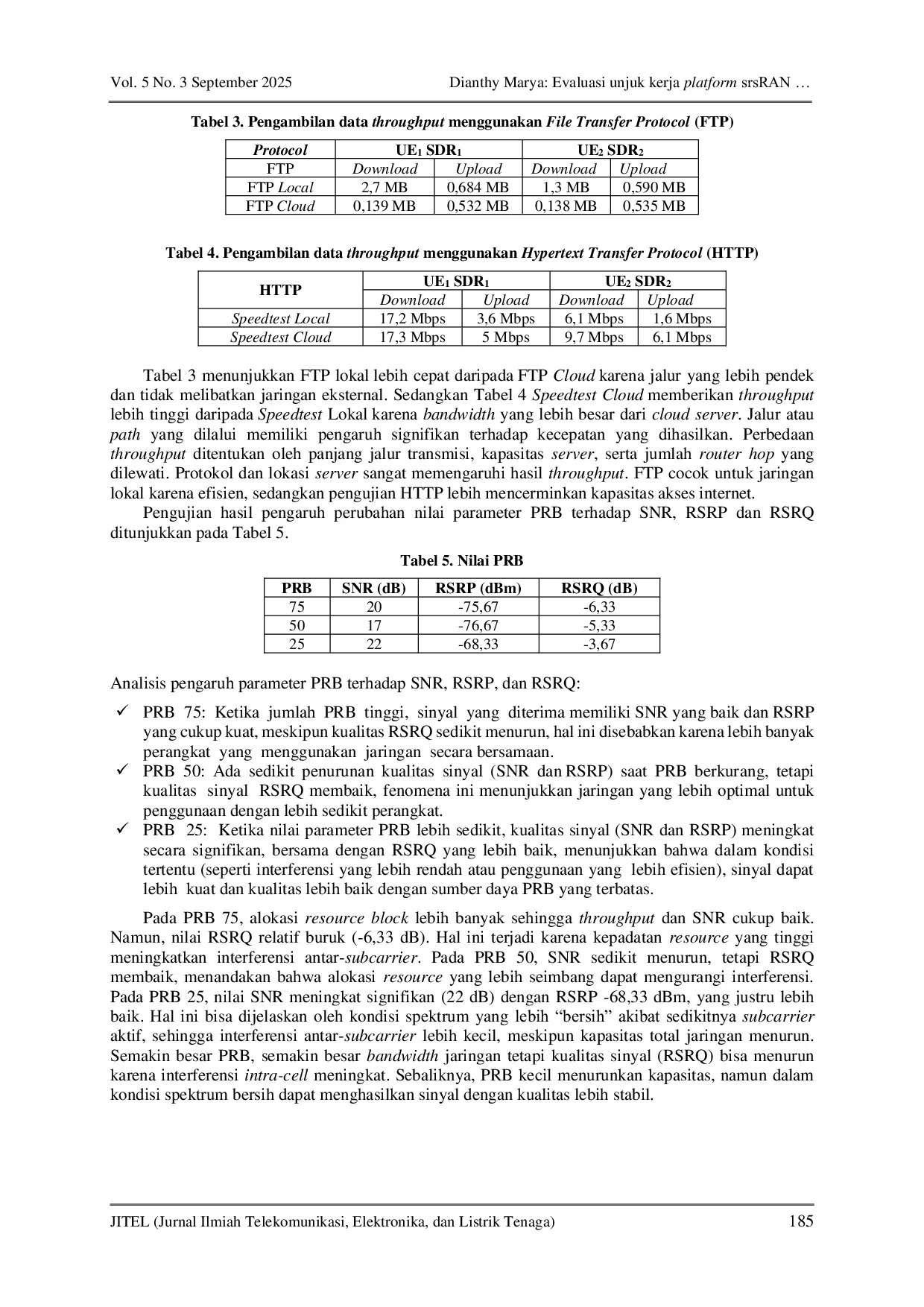

POLBANPOLBAN Hasil pengujian menunjukkan kedua UE berhasil terhubung: User 1 mencatat RSRP -83 dBm dan RSRQ -9 dB, sedangkan User 2 mendapat RSRP -82 dBm dan SNR 13Hasil pengujian menunjukkan kedua UE berhasil terhubung: User 1 mencatat RSRP -83 dBm dan RSRQ -9 dB, sedangkan User 2 mendapat RSRP -82 dBm dan SNR 13

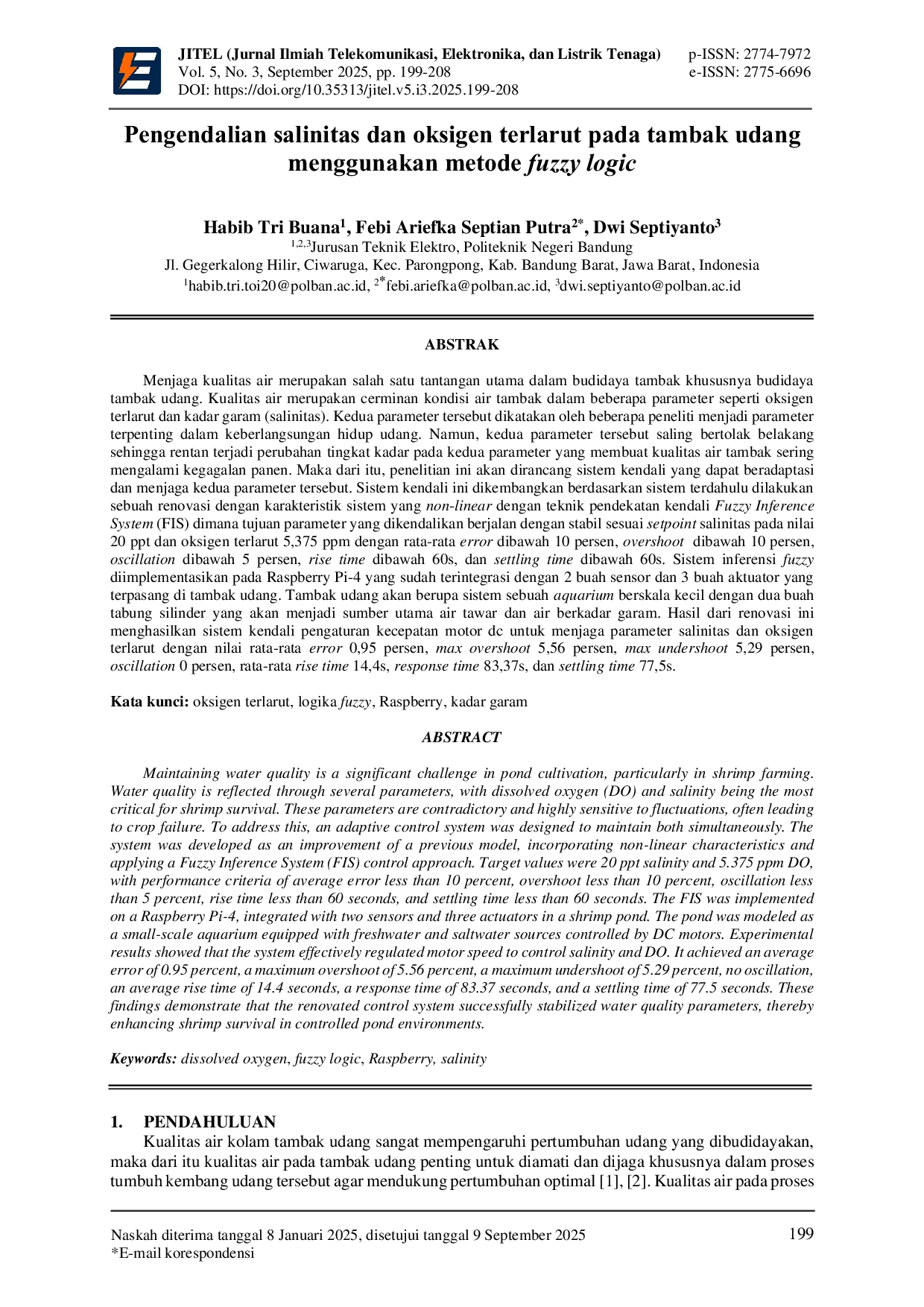

POLBANPOLBAN Tambak udang dimodelkan sebagai sistem akuarium berskala kecil dengan dua tabung silinder sebagai sumber air tawar dan air berkadar garam. Hasil renovasiTambak udang dimodelkan sebagai sistem akuarium berskala kecil dengan dua tabung silinder sebagai sumber air tawar dan air berkadar garam. Hasil renovasi

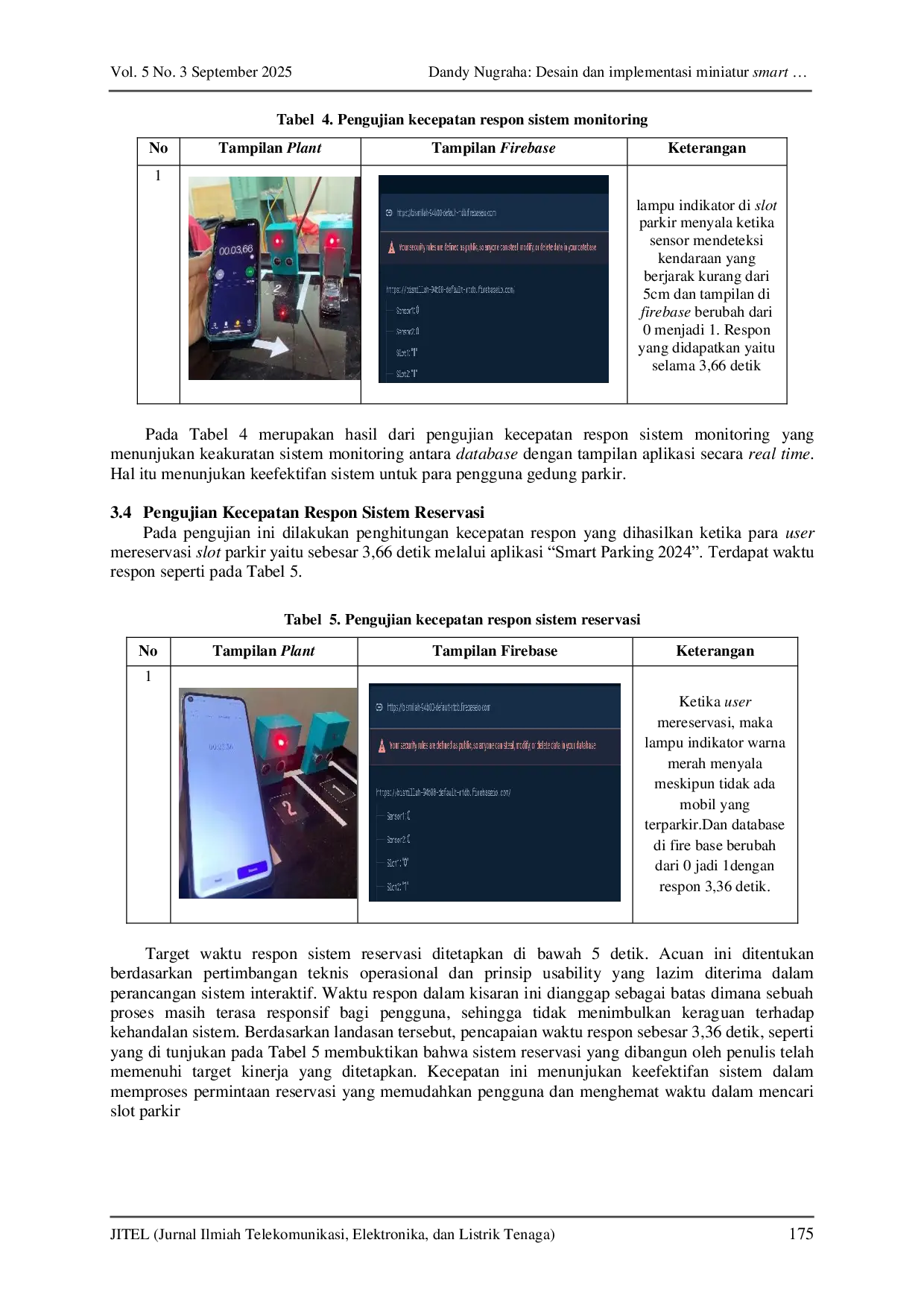

POLBANPOLBAN Implementasi sistem dilakukan dengan mengintegrasikan beberapa komponen, yaitu sensor ultrasonik sebagai pendeteksi mobil, servo untuk buka-tutup palang,Implementasi sistem dilakukan dengan mengintegrasikan beberapa komponen, yaitu sensor ultrasonik sebagai pendeteksi mobil, servo untuk buka-tutup palang,

STIEPARISTIEPARI Temuan ini menegaskan bahwa kedua faktor tersebut sangat penting untuk diperhatikan oleh manajemen dalam upaya meningkatkan kepuasan kerja karyawan. BerdasarkanTemuan ini menegaskan bahwa kedua faktor tersebut sangat penting untuk diperhatikan oleh manajemen dalam upaya meningkatkan kepuasan kerja karyawan. Berdasarkan

UMBUMB Konsep ini menekankan pentingnya melibatkan semua pemangku kepentingan dalam proses pengambilan keputusan dan mempertimbangkan sumber daya yang tersedia.Konsep ini menekankan pentingnya melibatkan semua pemangku kepentingan dalam proses pengambilan keputusan dan mempertimbangkan sumber daya yang tersedia.

UMBUMB Risiko teknologi dan risiko kegagalan aset adalah risiko yang paling tidak menjadi perhatian karena sebagian besar konversi WCO tidak dilakukan di Indonesia.Risiko teknologi dan risiko kegagalan aset adalah risiko yang paling tidak menjadi perhatian karena sebagian besar konversi WCO tidak dilakukan di Indonesia.

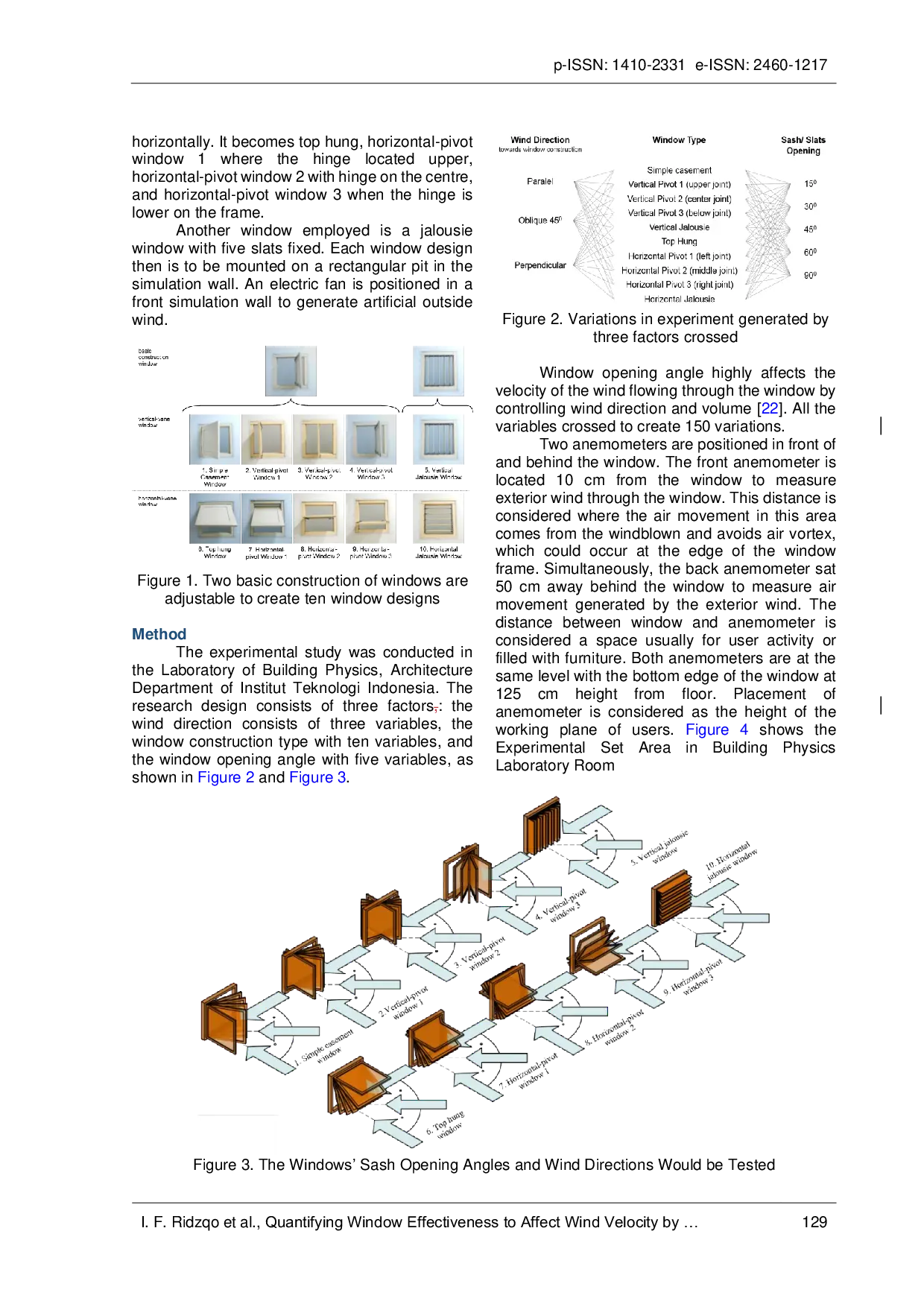

UMBUMB Jendela, sebagai salah satu bentuk ventilasi, memiliki berbagai desain yang menggabungkan tiga konstruksi utama: bukaan sederhana, pivots vertikal, danJendela, sebagai salah satu bentuk ventilasi, memiliki berbagai desain yang menggabungkan tiga konstruksi utama: bukaan sederhana, pivots vertikal, dan

Useful /

IJAR IAIKAPDIJAR IAIKAPD Pada level internasional, peningkatan kesadaran terhadap isu lingkungan telah mendorong berbagai negara untuk menaruh perhatian pada konsep keberlanjutan.Pada level internasional, peningkatan kesadaran terhadap isu lingkungan telah mendorong berbagai negara untuk menaruh perhatian pada konsep keberlanjutan.

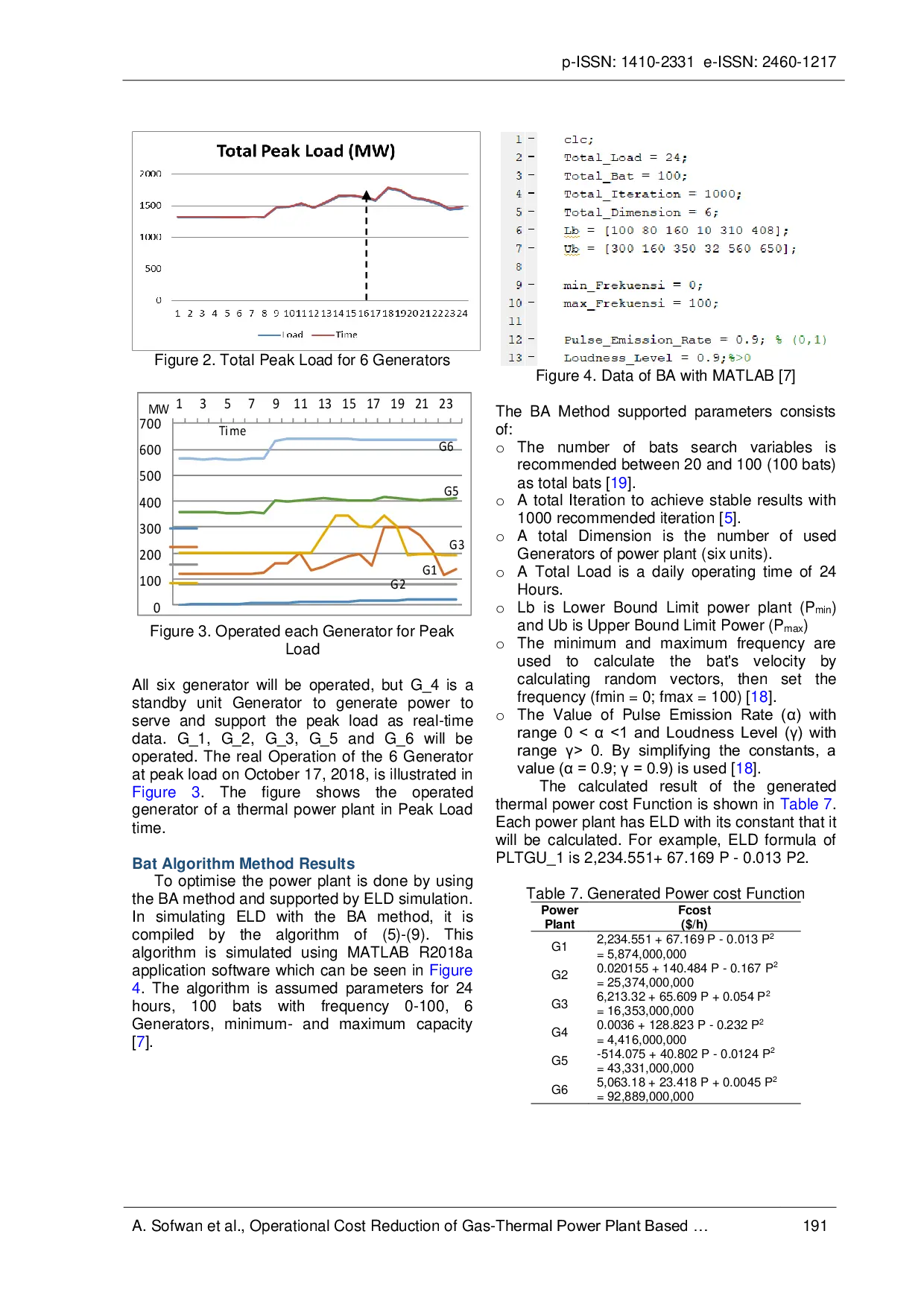

UMBUMB The BA method yielded a total operating cost of $1,653,374, representing a 16.85% reduction compared to the real-time operation cost of $1,988,410. TheThe BA method yielded a total operating cost of $1,653,374, representing a 16.85% reduction compared to the real-time operation cost of $1,988,410. The

UMBUMB Selain itu, koperasi digital juga harus mampu memanfaatkan teknologi seperti e-money, barcode scanner, dan RFID untuk meningkatkan efisiensi operasionalSelain itu, koperasi digital juga harus mampu memanfaatkan teknologi seperti e-money, barcode scanner, dan RFID untuk meningkatkan efisiensi operasional

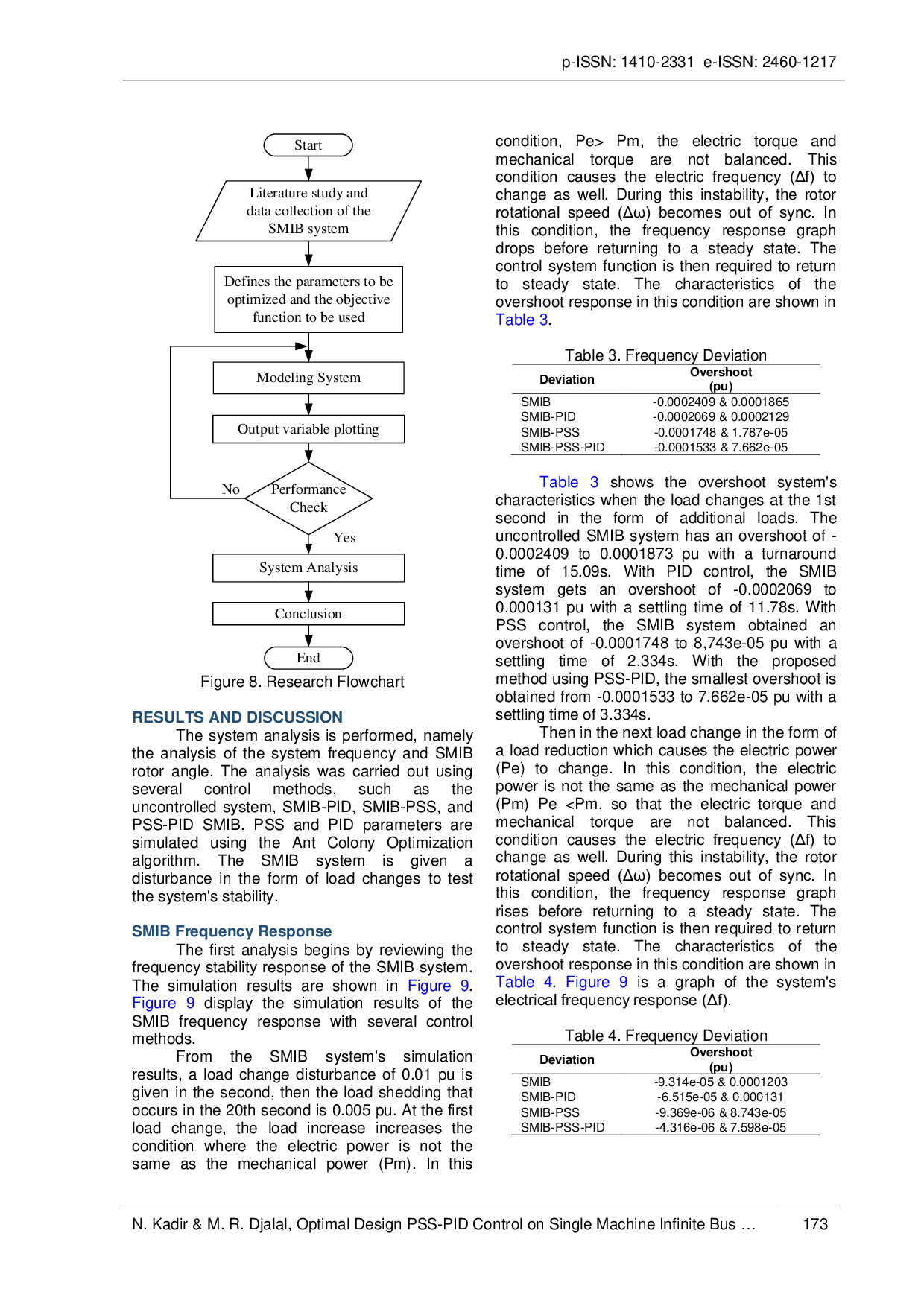

UMBUMB Dengan menggunakan metode cerdas berbasis Ant Colony, diperoleh parameter PSS-PID yang optimal. Dengan tuning optimal, sistem mendapatkan respons frekuensiDengan menggunakan metode cerdas berbasis Ant Colony, diperoleh parameter PSS-PID yang optimal. Dengan tuning optimal, sistem mendapatkan respons frekuensi