KIPMIKIPMI

Communications in Science and TechnologyCommunications in Science and TechnologyMalic acid is a valuable organic acid widely used in food, pharmaceutical, and chemical industries. It can be sustainably produced from underutilized molasses, often classified as waste. This study evaluated the feasibility of malic acid production from molasses, using Rhizopus arrhizus. A SuperPro Designer simulation integrated process design, economic analysis, and sensitivity evaluation and the results demonstrated economic viability with a Net Present Value (NPV) of $2,140,000 (7% discount rate), an Internal Rate of Return (IRR) of 15.81%, a Return on Investment (ROI) of 22.70, and a payback period (PP) of 4.40 years for an annual production capacity of 2,830 MT. Sensitivity analysis highlighted the selling price of malic acid as the most important economic factor. This feasibility study provides a novel approach to integrate molasses-based fermentation with simulation tools, offering actionable insights for industrial-scale implementation by quantifying key economic drivers.

The study demonstrates the economic viability of malic acid production from molasses using Rhizopus arrhizus, with promising financial indicators like an NPV of $2.81%, and a payback period of 4.The selling price of malic acid is identified as the most critical economic factor influencing the processs profitability.Further optimization of the fermentation process and downstream purification is crucial to enhance economic competitiveness and sustainability.

Future research should focus on enhancing the acid tolerance of R. arrhizus through strain modification or optimized process control to improve malic acid accumulation during fermentation. Investigating more intensive fermentation methods, such as fed-batch or continuous fermentation, could significantly reduce cycle times and increase volumetric productivity. Furthermore, developing more efficient and sustainable downstream processing strategies to minimize biofouling and waste generation is essential for improving the overall economic and environmental performance of the process. These advancements, coupled with a robust raw material sourcing strategy and quality control, will pave the way for the successful industrial implementation of malic acid production from molasses.

| File size | 628.62 KB |

| Pages | 10 |

| Short Link | https://juris.id/p-3rm |

| Lookup Links | Google ScholarGoogle Scholar, Semantic ScholarSemantic Scholar, CORE.ac.ukCORE.ac.uk, WorldcatWorldcat, ZenodoZenodo, Research GateResearch Gate, Academia.eduAcademia.edu, OpenAlexOpenAlex, Hollis HarvardHollis Harvard |

| DMCA | Report |

Related /

KIPMIKIPMI Analisis biaya operasional menunjukkan biaya tahunan sebesar IDR 907.960,32, namun diperlukan analisis teknis dan ekonomi yang lebih detail untuk membandingkanAnalisis biaya operasional menunjukkan biaya tahunan sebesar IDR 907.960,32, namun diperlukan analisis teknis dan ekonomi yang lebih detail untuk membandingkan

KIPMIKIPMI The hydrothermal modification of GAC enhanced bacterial immobilization and electron transfer, contributing to improved biodegradation performance. GasThe hydrothermal modification of GAC enhanced bacterial immobilization and electron transfer, contributing to improved biodegradation performance. Gas

KIPMIKIPMI Kebaruan dari pekerjaan ini terletak pada penggunaan pembelajaran ensemble terintegrasi untuk menangkap interaksi kompleks dan non-linear antara kimiaKebaruan dari pekerjaan ini terletak pada penggunaan pembelajaran ensemble terintegrasi untuk menangkap interaksi kompleks dan non-linear antara kimia

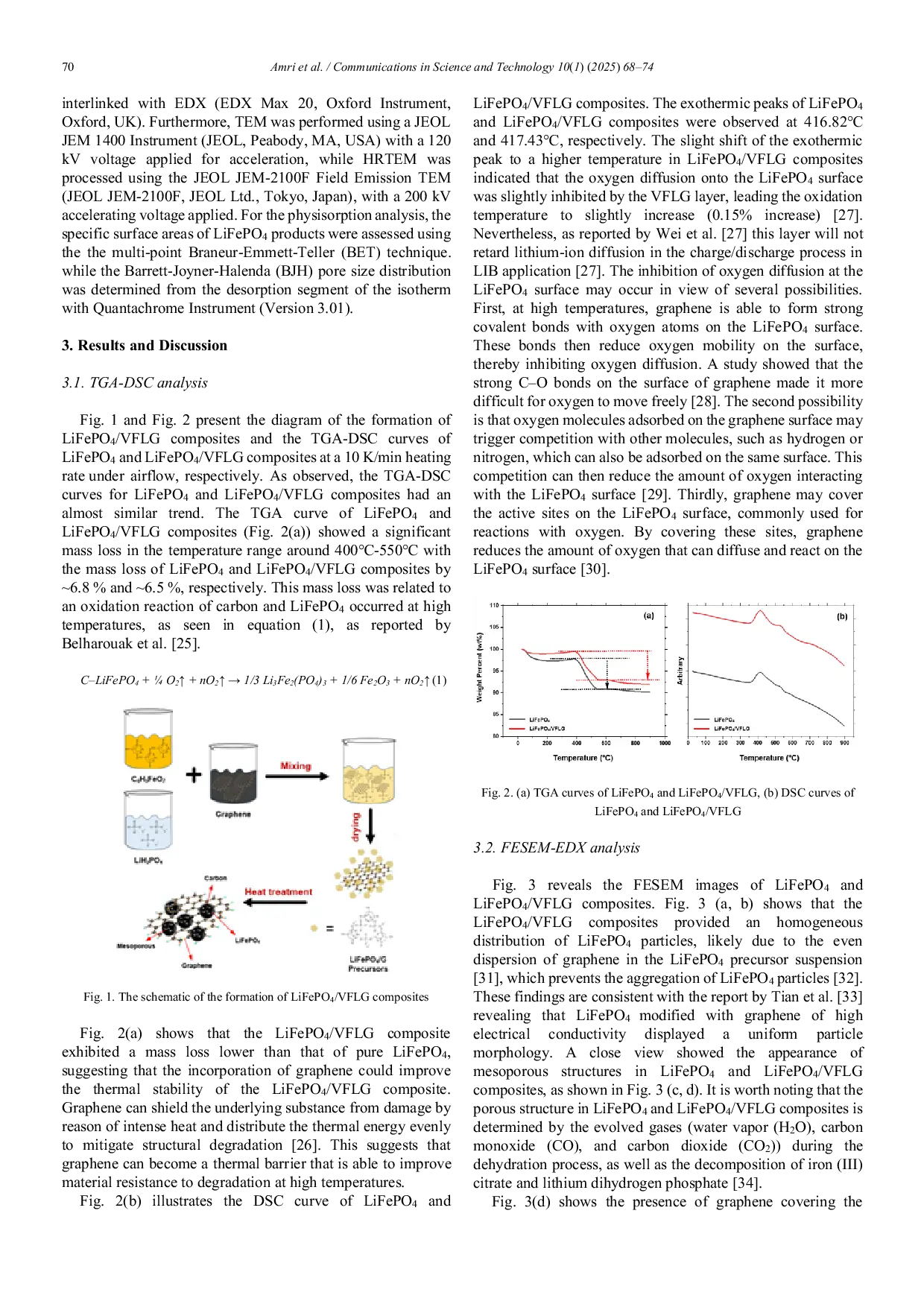

KIPMIKIPMI VFLG diperoleh dari proses eksfoliasi shear dinamika fluida yang sederhana, efektif biaya, dan ramah lingkungan. Komposit LiFePO4/VFLG yang disiapkan melaluiVFLG diperoleh dari proses eksfoliasi shear dinamika fluida yang sederhana, efektif biaya, dan ramah lingkungan. Komposit LiFePO4/VFLG yang disiapkan melalui

KIPMIKIPMI Studi ini mengusulkan pengembangan perangkat pemulihan energi yang memanfaatkan panas knalpot sebagai energi listrik menggunakan generator termoelektrikStudi ini mengusulkan pengembangan perangkat pemulihan energi yang memanfaatkan panas knalpot sebagai energi listrik menggunakan generator termoelektrik

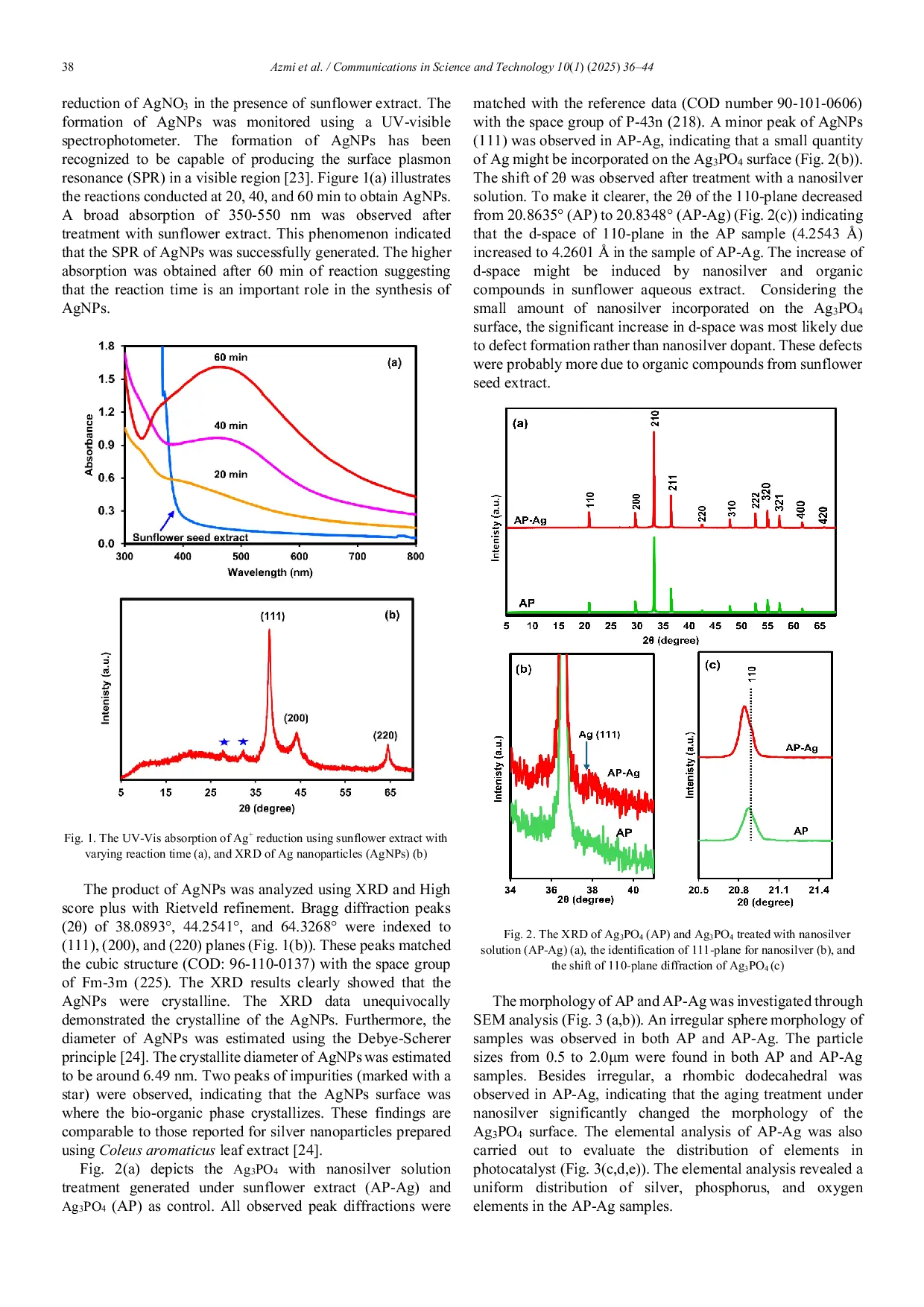

KIPMIKIPMI Fotokatalis ini disiapkan melalui kopresipitasi kimia. Berdasarkan analisis XPS, interaksi larutan nanoperak dengan permukaan Ag3PO4 secara signifikanFotokatalis ini disiapkan melalui kopresipitasi kimia. Berdasarkan analisis XPS, interaksi larutan nanoperak dengan permukaan Ag3PO4 secara signifikan

KIPMIKIPMI Akurasi dievaluasi menggunakan fotogrametri UAV dan dibandingkan dengan data geodetik GPS. Pengaturan GCP vertikal menghasilkan akurasi tertinggi, mengurangiAkurasi dievaluasi menggunakan fotogrametri UAV dan dibandingkan dengan data geodetik GPS. Pengaturan GCP vertikal menghasilkan akurasi tertinggi, mengurangi

KIPMIKIPMI Meskipun katalis ZnO berpotensi untuk penangani limbah air, efisiensinya yang rendah membatasi komersialisasi. Untuk mengatasi masalah ini, efek kodopingMeskipun katalis ZnO berpotensi untuk penangani limbah air, efisiensinya yang rendah membatasi komersialisasi. Untuk mengatasi masalah ini, efek kodoping

Useful /

KIPMIKIPMI Penelitian ini mengoptimalkan Ekstraksi Berbantuan Ultrasonik (Ultrasound-Assisted Extraction - UAE) kayu secang (Caesalpinia sappan L. ) menggunakan CentralPenelitian ini mengoptimalkan Ekstraksi Berbantuan Ultrasonik (Ultrasound-Assisted Extraction - UAE) kayu secang (Caesalpinia sappan L. ) menggunakan Central

KIPMIKIPMI Maximum E. coli adsorption capacities were found at 572,967 CFU/cm2 for ATA foil-1 and 561,513 CFU/cm2 for ATA foil-2. Both foils achieved over 84% methylMaximum E. coli adsorption capacities were found at 572,967 CFU/cm2 for ATA foil-1 and 561,513 CFU/cm2 for ATA foil-2. Both foils achieved over 84% methyl

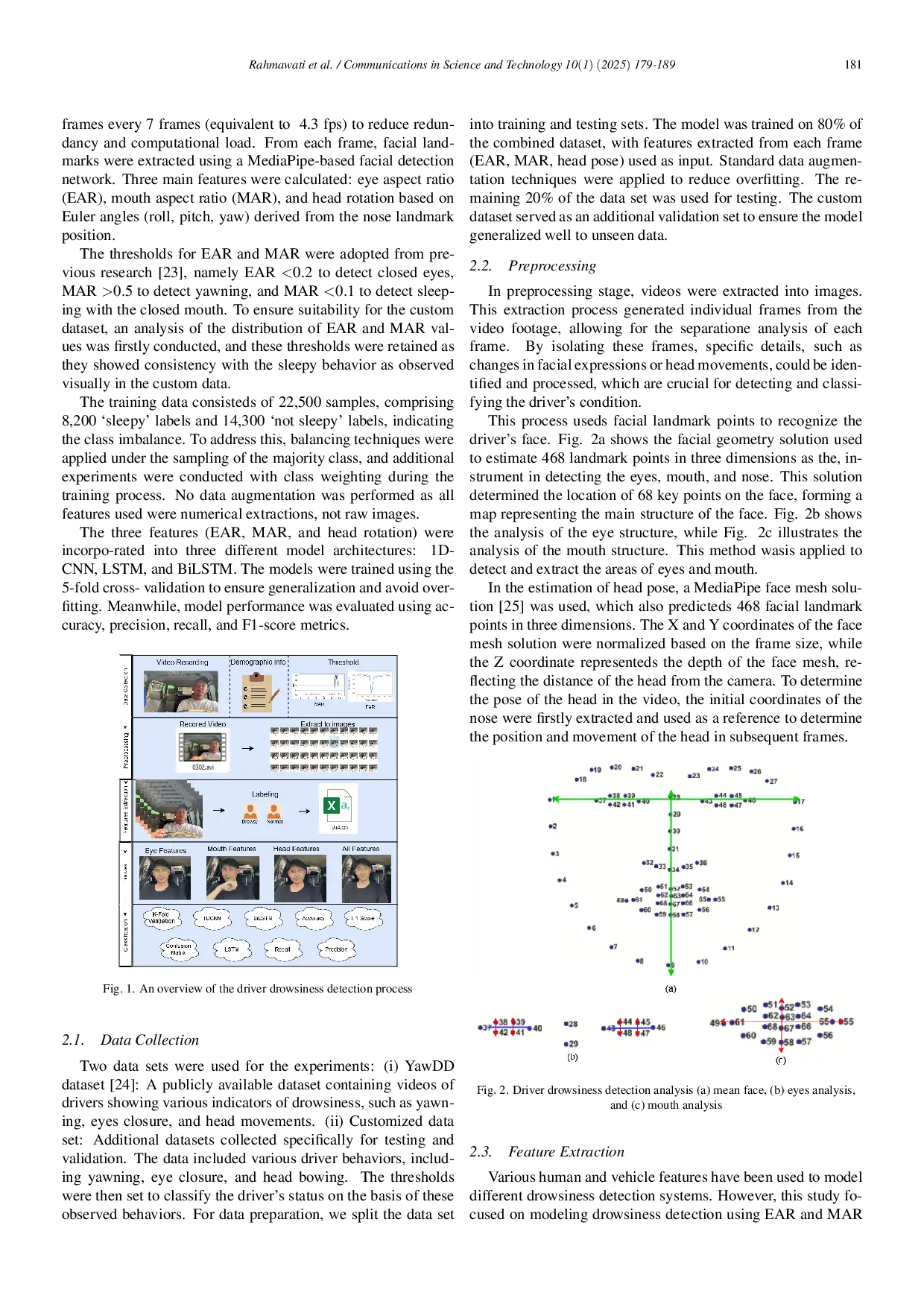

KIPMIKIPMI Sistem menggunakan landmark wajah yang dihasilkan oleh detektor jaringan wajah untuk mengidentifikasi area-area kunci seperti mata, mulut, dan kepala.Sistem menggunakan landmark wajah yang dihasilkan oleh detektor jaringan wajah untuk mengidentifikasi area-area kunci seperti mata, mulut, dan kepala.

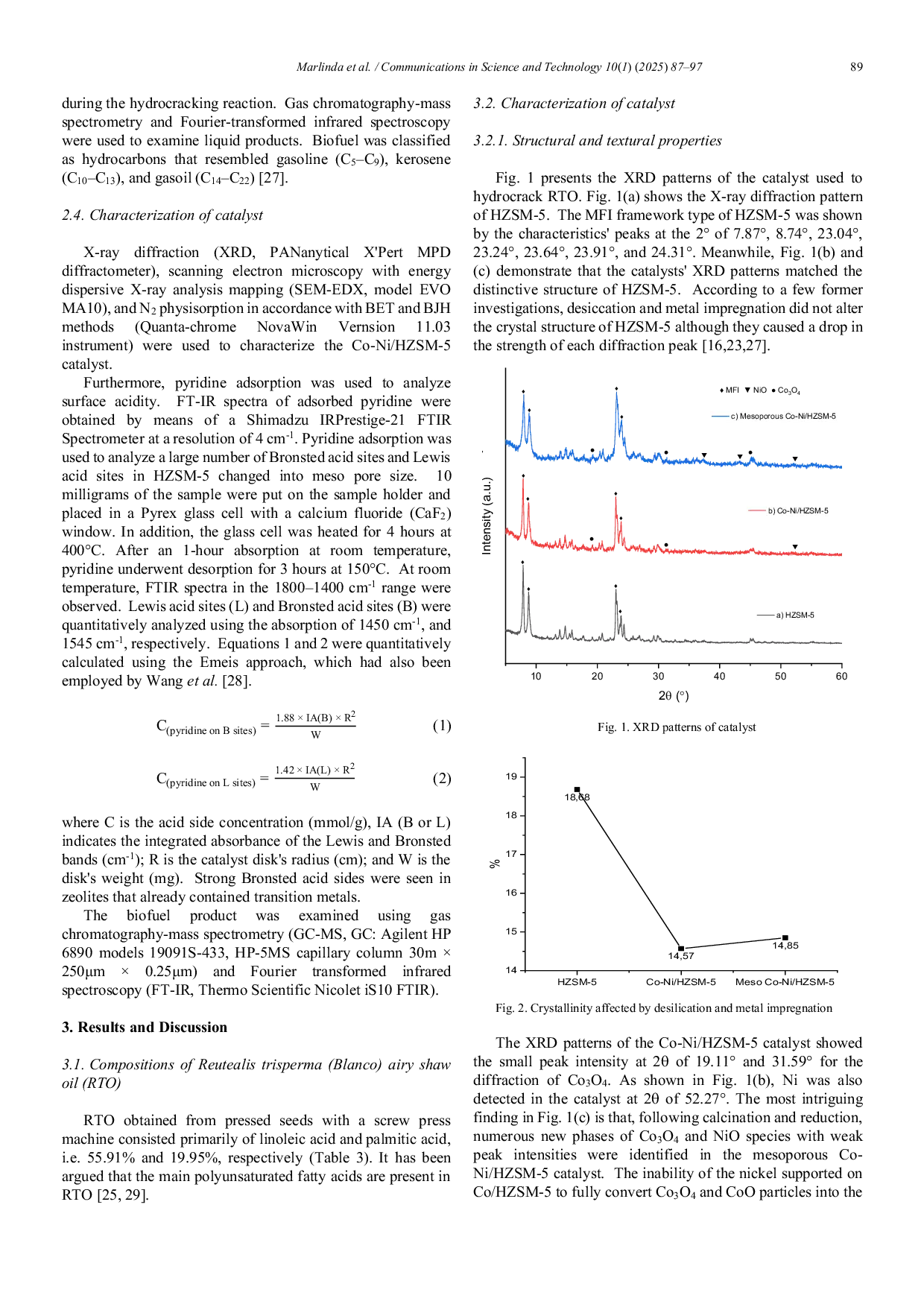

KIPMIKIPMI Hasil penelitian menunjukkan bahwa kombinasi desilasi dan impregnasi Co-Ni meningkatkan jumlah senyawa hidrokarbon, seperti n-paraffin, isoparaffin, sikloparafin,Hasil penelitian menunjukkan bahwa kombinasi desilasi dan impregnasi Co-Ni meningkatkan jumlah senyawa hidrokarbon, seperti n-paraffin, isoparaffin, sikloparafin,