UMBUMB

SINERGISINERGIBone implants are medical procedures involving replacement or reconstruction of missing or damaged bones. The widely used bone cement is a polymethylmethacrylate (PMMA) based composite material. To improve bioactivity, PMMA is combined with hydroxyapatite (HA). Manual formation of bone implants can be time-consuming and prone to errors. Therefore, 3D printing technology is used to improve the quality of bone implants. This study aims to determine the effect of three parameters – perimeter speed, infill speed, and fill angle – on the dimensional accuracy of prints using a 3D printing machine. A response surface experiment design was used to determine the effect of these parameters on dimensional error. The results show that these three factors have no significant impact on the dimensional error, but the resulting error is still high. Therefore, it is necessary to adjust the design size before printing.

The study concludes that the tested machine parameters (perimeter speed, infill speed, and fill angle) do not significantly affect specimen dimensions.The 3D printing machine can produce specimens with relatively consistent dimensions within the tested parameter range.However, the resulting dimensional error remains substantial, indicating the need for further investigation into other factors influencing accuracy.Therefore, future research should focus on identifying and optimizing additional parameters to minimize dimensional errors in 3D-printed biocomposite materials.

Berdasarkan hasil penelitian ini, beberapa saran penelitian lanjutan dapat diajukan. Pertama, perlu dilakukan investigasi lebih mendalam mengenai pengaruh parameter mesin lain yang belum dieksplorasi, seperti suhu nozzle, kecepatan pendinginan, dan jenis material umpan, terhadap akurasi dimensi hasil cetak. Kedua, penelitian selanjutnya dapat berfokus pada pengembangan desain spesimen yang lebih kompleks dan representatif terhadap bentuk implan tulang yang sebenarnya, untuk menguji kemampuan mesin dalam menghasilkan geometri yang rumit dengan akurasi yang memadai. Ketiga, eksplorasi penggunaan material biokomposit alternatif dengan komposisi yang berbeda, seperti variasi persentase hidroksiapatit atau penambahan material penguat lainnya, dapat dilakukan untuk meningkatkan sifat mekanik dan bioaktivitas implan tulang yang dicetak 3D. Penelitian-penelitian ini diharapkan dapat memberikan pemahaman yang lebih komprehensif mengenai potensi dan keterbatasan teknologi 3D printing dalam pembuatan implan tulang yang berkualitas tinggi dan sesuai dengan kebutuhan pasien.

- THE EFFECT OF 3D PRINTING MACHINE PARAMETERS IN EXTRUSION PROCESS OF BIOCOMPOSITE MATERIALS (PMMA AND... doi.org/10.22441/sinergi.2018.2.003THE EFFECT OF 3D PRINTING MACHINE PARAMETERS IN EXTRUSION PROCESS OF BIOCOMPOSITE MATERIALS PMMA AND doi 10 22441 sinergi 2018 2 003

- Polymer Composites for Bone Reconstruction | IntechOpen. polymer composites bone intechopen open access... doi.org/10.5772/20657Polymer Composites for Bone Reconstruction IntechOpen polymer composites bone intechopen open access doi 10 5772 20657

| File size | 517.7 KB |

| Pages | 8 |

| DMCA | Report |

Related /

STIE MCESTIE MCE Dengan menggunakan model regresi Poisson untuk menguji hipotesis, kami menemukan bahwa seiring meningkatnya tekanan pada rantai pasokan, perusahaan melakukanDengan menggunakan model regresi Poisson untuk menguji hipotesis, kami menemukan bahwa seiring meningkatnya tekanan pada rantai pasokan, perusahaan melakukan

UNHAJUNHAJ In addition, ginger can also be processed into a balm preparation that is more practical and easy to use. The purpose of this community service activityIn addition, ginger can also be processed into a balm preparation that is more practical and easy to use. The purpose of this community service activity

UNHAJUNHAJ Selain itu, diberikan sarana kesehatan seperti timbangan, obat-obatan, vitamin, dan fasilitas penyimpanan kepada perangkat desa. Hasilnya menunjukkan peningkatanSelain itu, diberikan sarana kesehatan seperti timbangan, obat-obatan, vitamin, dan fasilitas penyimpanan kepada perangkat desa. Hasilnya menunjukkan peningkatan

UNHAJUNHAJ Sedangkan, tingkat pengetahuan PKK tentang Beyond Use Date (BUD) pada kuesioner Postest termasuk dalam kategori pengetahuan baik (75-100%) dengan nilaiSedangkan, tingkat pengetahuan PKK tentang Beyond Use Date (BUD) pada kuesioner Postest termasuk dalam kategori pengetahuan baik (75-100%) dengan nilai

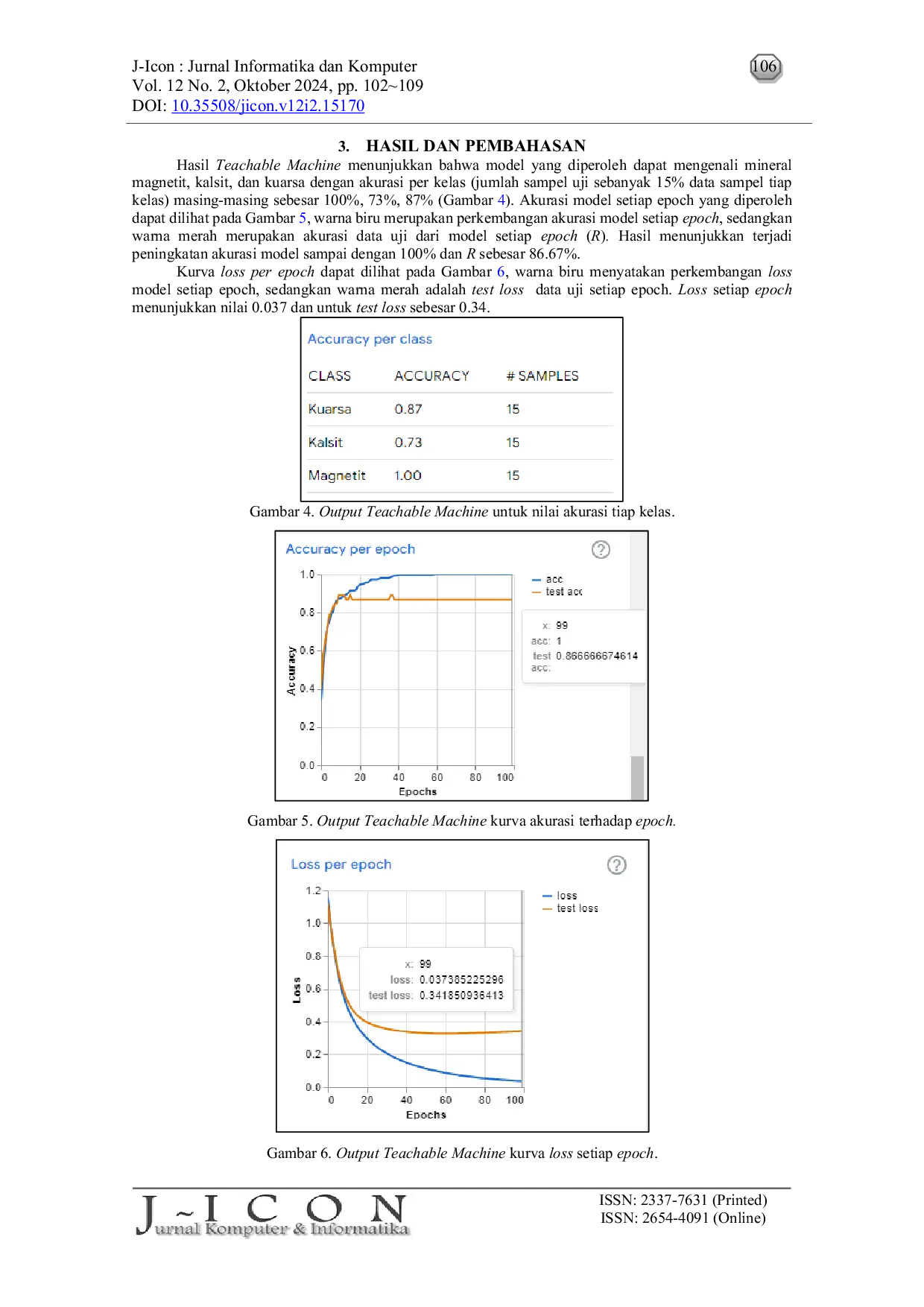

UNDANAUNDANA Berdasarkan hasil yang diperoleh dapat disimpulkan Teachable Machine sebagai aplikasi berbasis website dapat dimanfaatkan dengan efektif dan mudah dalamBerdasarkan hasil yang diperoleh dapat disimpulkan Teachable Machine sebagai aplikasi berbasis website dapat dimanfaatkan dengan efektif dan mudah dalam

HKBPHKBP Selain itu, produk prototipe cepat juga dapat digunakan untuk menguji bagian tertentu. Dalam proses desain, digunakan perangkat lunak Solidworks 2017 danSelain itu, produk prototipe cepat juga dapat digunakan untuk menguji bagian tertentu. Dalam proses desain, digunakan perangkat lunak Solidworks 2017 dan

UMBUMB Saat ini belum tersedia standar konsumsi energi spesifik (SEC) di industri minyak kelapa sawit; padahal SEC sangat berguna sebagai indikator optimalitasSaat ini belum tersedia standar konsumsi energi spesifik (SEC) di industri minyak kelapa sawit; padahal SEC sangat berguna sebagai indikator optimalitas

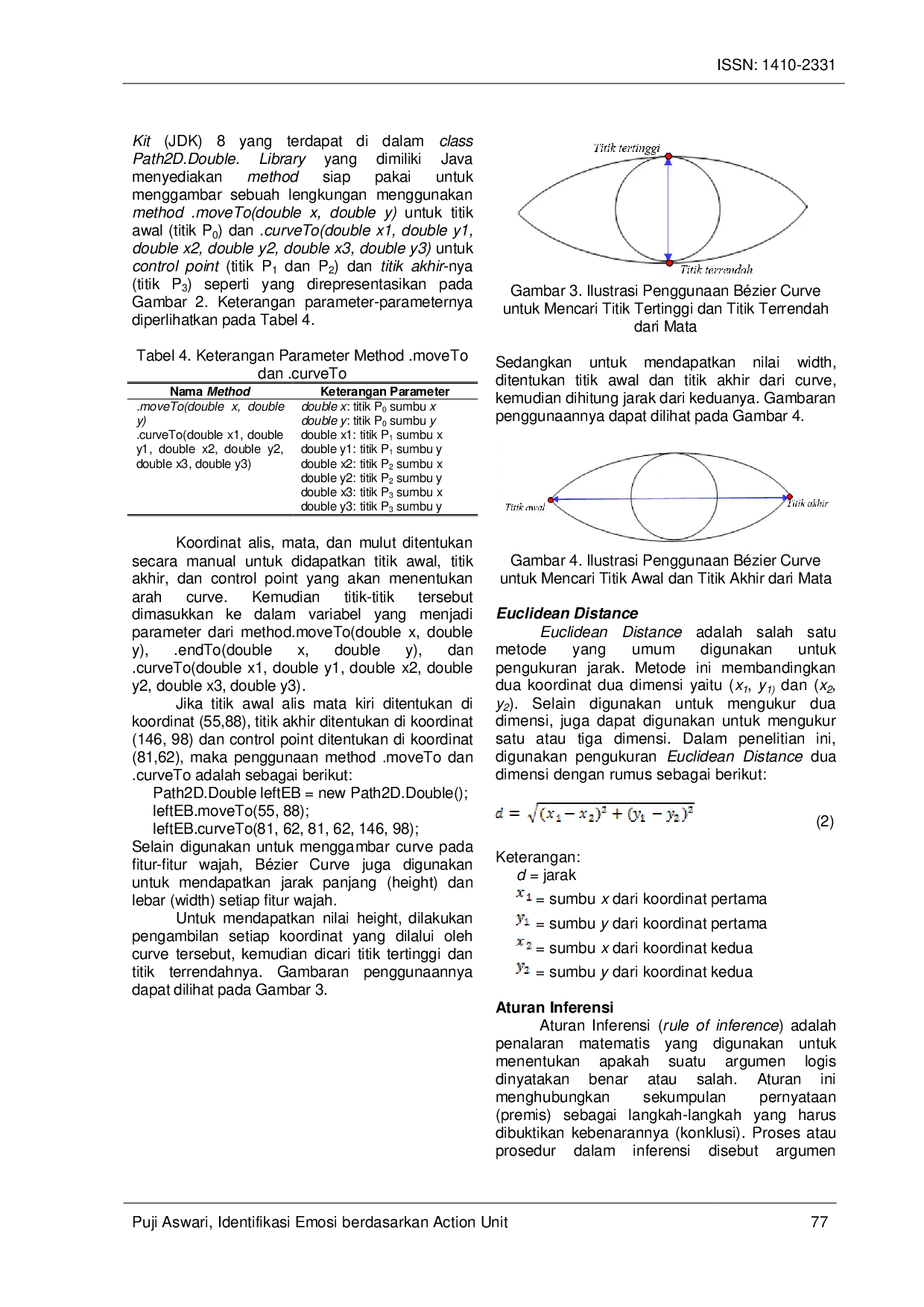

UMBUMB FACS menentukan ekspresi wajah berdasarkan pergerakan otot wajah, yang diistilahkan Action Unit (AU). Penelitian ini bertujuan untuk mengetahui emosi tertarikFACS menentukan ekspresi wajah berdasarkan pergerakan otot wajah, yang diistilahkan Action Unit (AU). Penelitian ini bertujuan untuk mengetahui emosi tertarik

Useful /

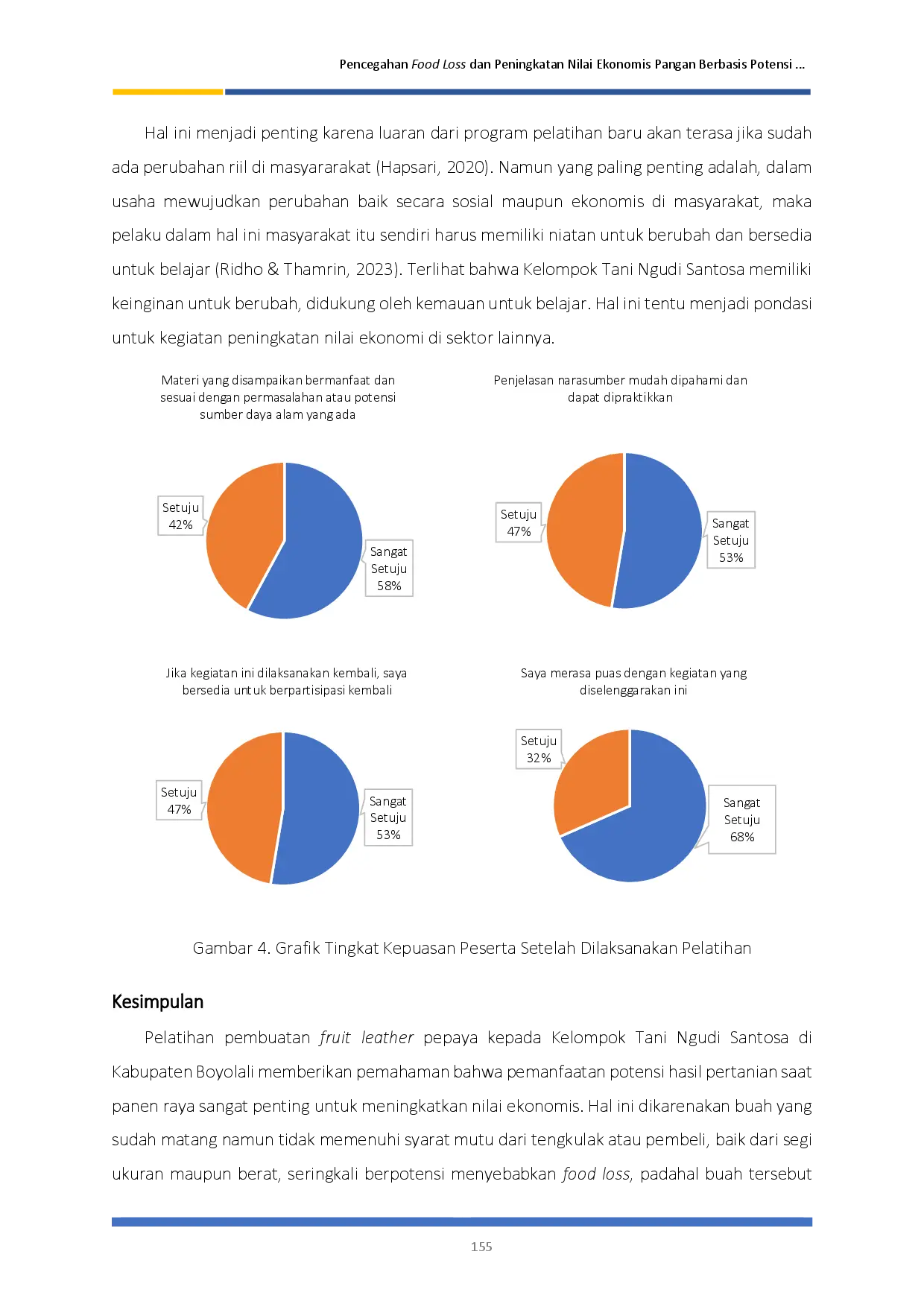

UBUB Tahapan pelaksanaan terdiri dari tahap prapelatihan dan pascapelatihan. Sebelum dilaksanakan pelatihan pembuatan fruit leather pepaya, sebesar 89,47% anggotaTahapan pelaksanaan terdiri dari tahap prapelatihan dan pascapelatihan. Sebelum dilaksanakan pelatihan pembuatan fruit leather pepaya, sebesar 89,47% anggota

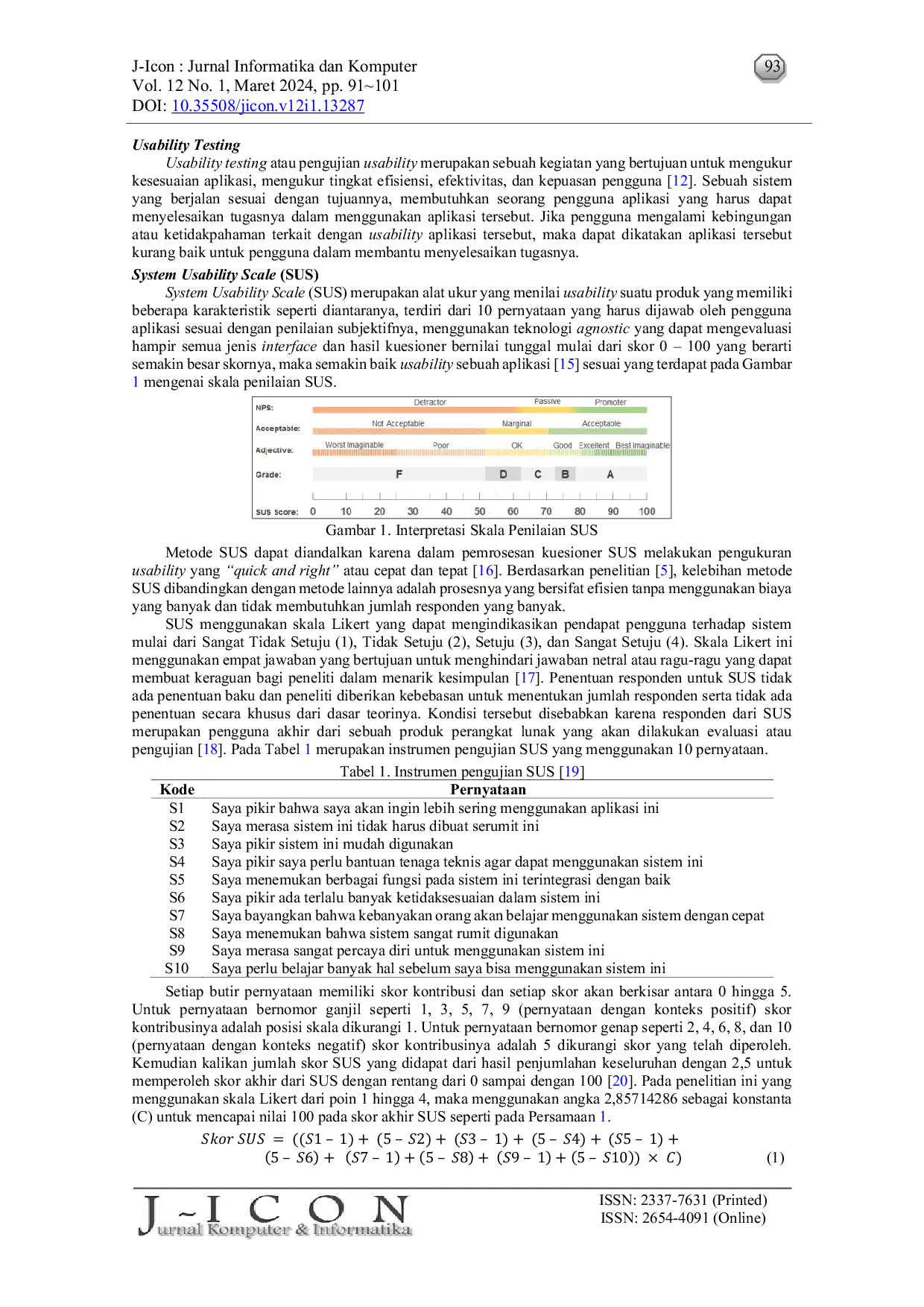

UNDANAUNDANA Aplikasi Kampus Kita Tendik merupakan sebuah aplikasi berbasis mobile yang dikembangkan oleh Universitas Airlangga untuk mengelola dan mengatur kinerjaAplikasi Kampus Kita Tendik merupakan sebuah aplikasi berbasis mobile yang dikembangkan oleh Universitas Airlangga untuk mengelola dan mengatur kinerja

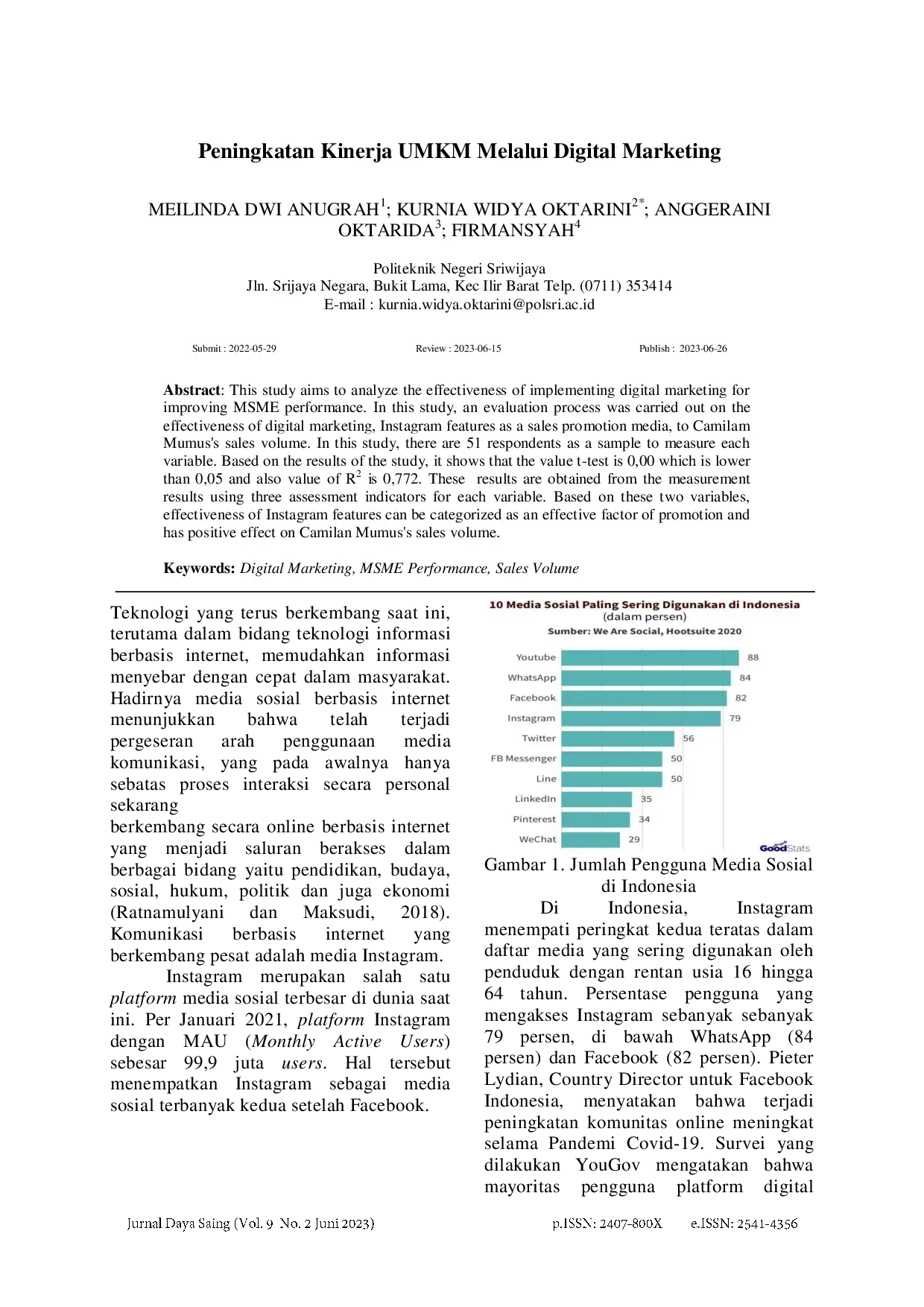

KOMPETIFKOMPETIF Berdasarkan data yang diperoleh dan dilakukan pengujian, maka disimpulkan bahwa digital marketing berpengaruh positif terhadap volume penjualan pada UMKMBerdasarkan data yang diperoleh dan dilakukan pengujian, maka disimpulkan bahwa digital marketing berpengaruh positif terhadap volume penjualan pada UMKM

UNDANAUNDANA Pengujian dilakukan untuk menemukan kegagalan atau masalah pada aplikasi, memastikan semua fungsionalitas dan non fungsionalitas sesuai dengan requirement,Pengujian dilakukan untuk menemukan kegagalan atau masalah pada aplikasi, memastikan semua fungsionalitas dan non fungsionalitas sesuai dengan requirement,