AIRAAIRA

Journal of Information Systems and Technology ResearchJournal of Information Systems and Technology ResearchThe coal production and distribution industry faces persistent challenges in data management, operational coordination, and decision-making efficiency. Conventional monitoring methods often result in delayed reporting, low data accuracy, and limited adaptability to dynamic market demands. This study addresses the lack of an intelligent and integrated information system by designing and developing a real-time IoT-based solution for coal production and distribution management. The system was built using the Software Development Life Cycle (SDLC) with the Waterfall model and integrates IoT sensors to automatically capture critical parameters such as pressure, temperature, and coal quality indicators. Artificial Intelligence (AI) components were incorporated to enhance data analysis and support predictive decision-making. System evaluation through simulation with dummy data demonstrated notable improvements, including a 40% reduction in reporting response time and a 95% increase in operational data accuracy. The system also enabled faster production monitoring, streamlined distribution processes, and provided decision-makers with reliable real-time insights. User feedback confirmed the systems effectiveness in improving accessibility, monitoring efficiency, and overall operational performance in coal production and distribution management.

This study successfully designed, developed, and evaluated a real-time IoT-based integrated information system to address inefficiencies in coal production and distribution management.The system demonstrated significant performance improvements, reducing reporting response time by up to 40% and increasing data accuracy to 95%.These findings underscore the importance of adopting digital transformation technologies like IoT and AI in the coal industry to enhance operational efficiency, safety, and long-term competitiveness.

Berdasarkan hasil penelitian ini, beberapa saran penelitian lanjutan dapat dipertimbangkan. Pertama, penelitian lebih lanjut dapat dilakukan untuk menguji sistem ini dalam lingkungan operasional yang sesungguhnya di tambang batu bara, dengan mempertimbangkan tantangan konektivitas jaringan dan ketahanan perangkat keras. Kedua, pengembangan model prediktif berbasis AI dapat diperluas untuk memprediksi potensi kegagalan peralatan dan mengoptimalkan jadwal pemeliharaan, sehingga mengurangi waktu henti dan meningkatkan efisiensi produksi. Ketiga, integrasi sistem ini dengan teknologi lain seperti drone dan citra satelit dapat memberikan pemantauan yang lebih komprehensif terhadap area pertambangan, memungkinkan deteksi dini masalah lingkungan dan peningkatan keselamatan kerja. Penelitian-penelitian ini diharapkan dapat memberikan kontribusi signifikan dalam mendorong adopsi teknologi digital di industri pertambangan batu bara dan meningkatkan keberlanjutan operasionalnya.

- Coal loading comprehensive supervision system based on the Internet | Atlantis Press. coal loading supervision... atlantis-press.com/proceedings/iccmcee-15/25839787Coal loading comprehensive supervision system based on the Internet Atlantis Press coal loading supervision atlantis press proceedings iccmcee 15 25839787

- Design and Implementation of Coal Mine Safety Monitoring System Based on GIS - Zhang - 2022 - Wireless... doi.org/10.1155/2022/4771395Design and Implementation of Coal Mine Safety Monitoring System Based on GIS Zhang 2022 Wireless doi 10 1155 2022 4771395

| File size | 1.27 MB |

| Pages | 8 |

| DMCA | Report |

Related /

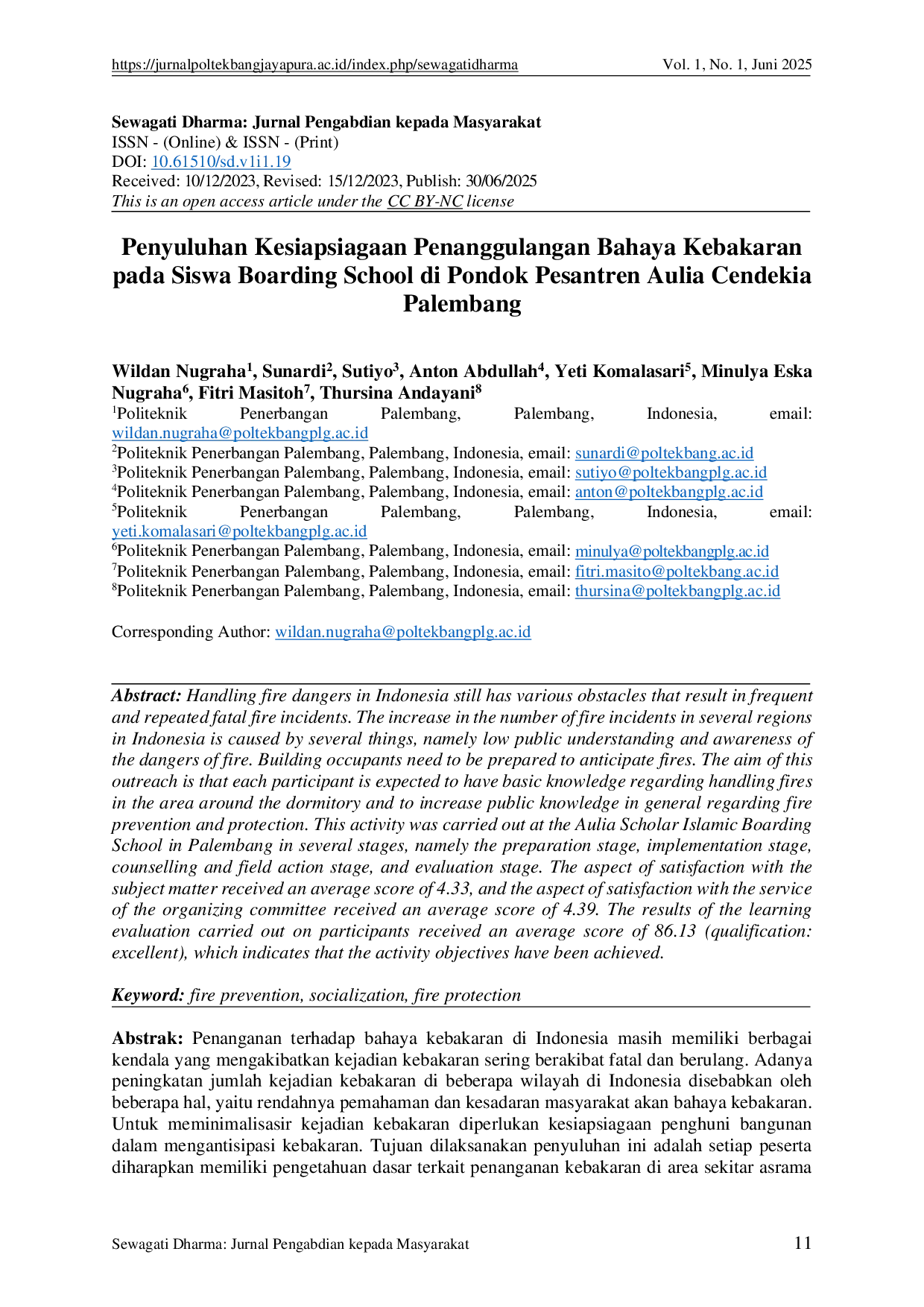

JURNALPOLTEKBANGJAYAPURAJURNALPOLTEKBANGJAYAPURA Penanganan terhadap bahaya kebakaran di Indonesia masih memiliki berbagai kendala yang mengakibatkan kejadian kebakaran sering berakibat fatal dan berulang.Penanganan terhadap bahaya kebakaran di Indonesia masih memiliki berbagai kendala yang mengakibatkan kejadian kebakaran sering berakibat fatal dan berulang.

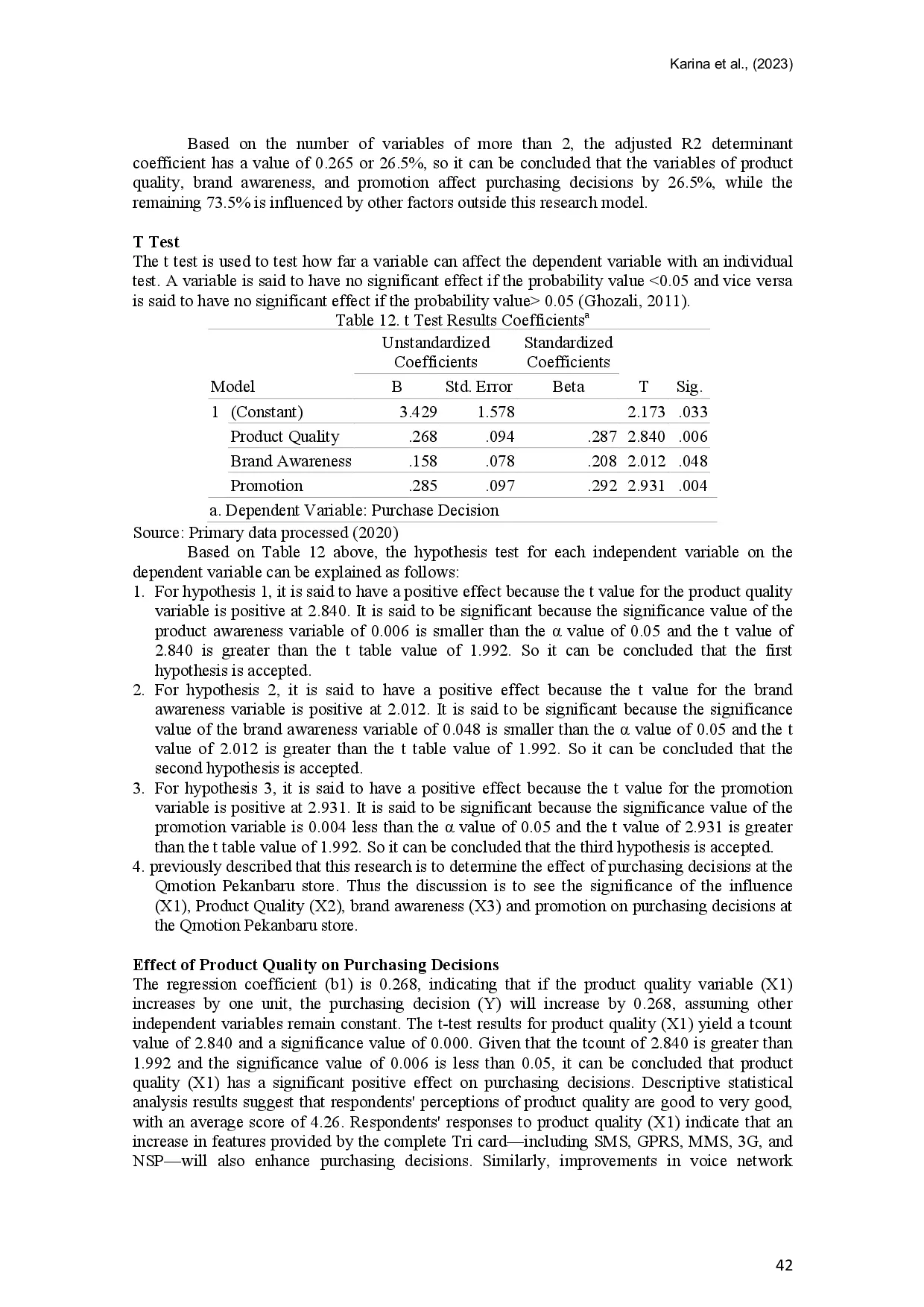

AL MATANIAL MATANI Hasil penelitian ini menunjukkan bahwa variabel kualitas produk, kesadaran merek, dan promosi memiliki pengaruh positif dan signifikan terhadap niat pembelian.Hasil penelitian ini menunjukkan bahwa variabel kualitas produk, kesadaran merek, dan promosi memiliki pengaruh positif dan signifikan terhadap niat pembelian.

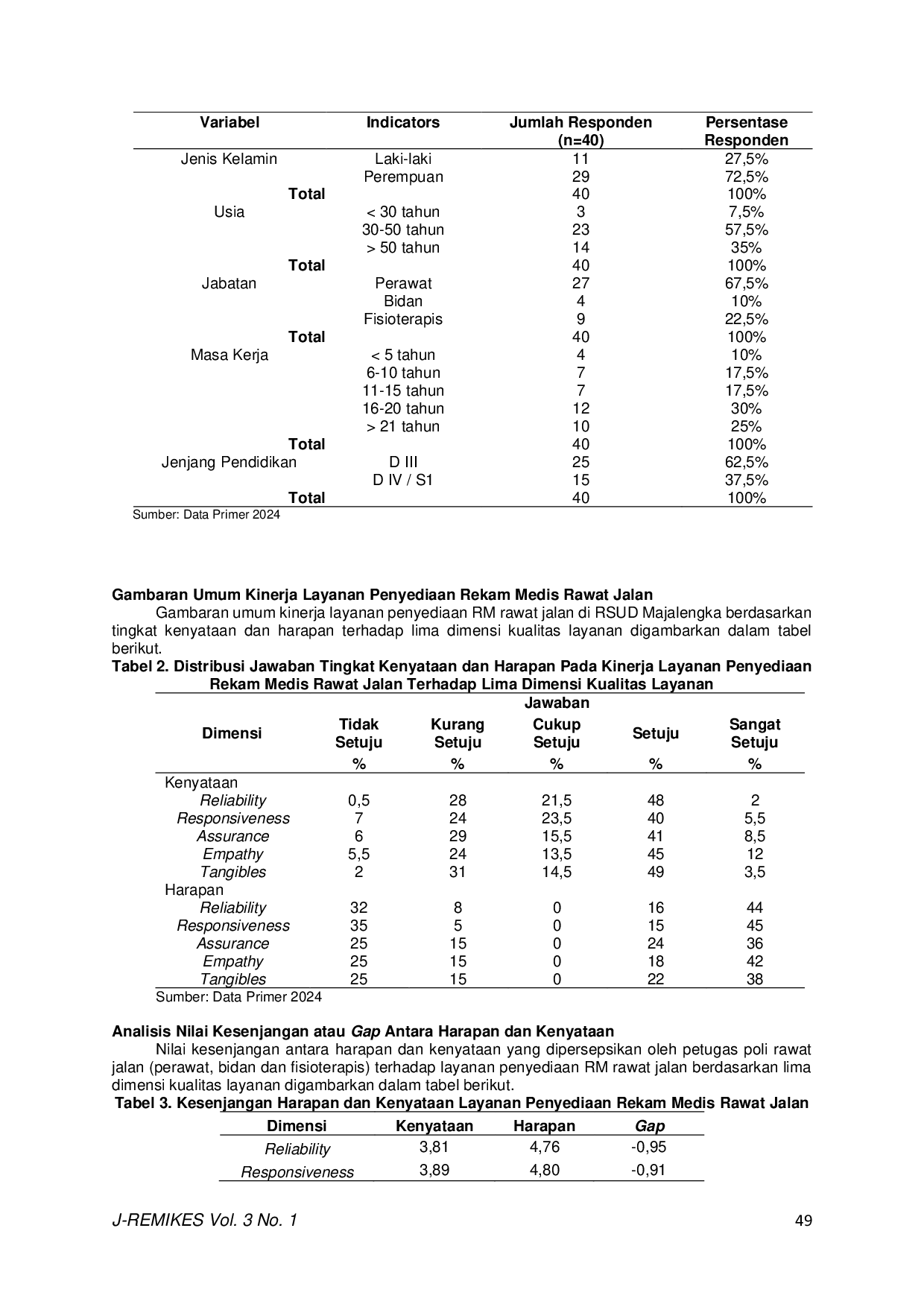

POLTEKKESTASIKMALAYAPOLTEKKESTASIKMALAYA Nilai kesenjangan atau gap untuk semua dimensi kualitas layanan bernilai negatif. Tingkat kepuasan petugas poli rawat jalan terhadap layanan penyediaanNilai kesenjangan atau gap untuk semua dimensi kualitas layanan bernilai negatif. Tingkat kepuasan petugas poli rawat jalan terhadap layanan penyediaan

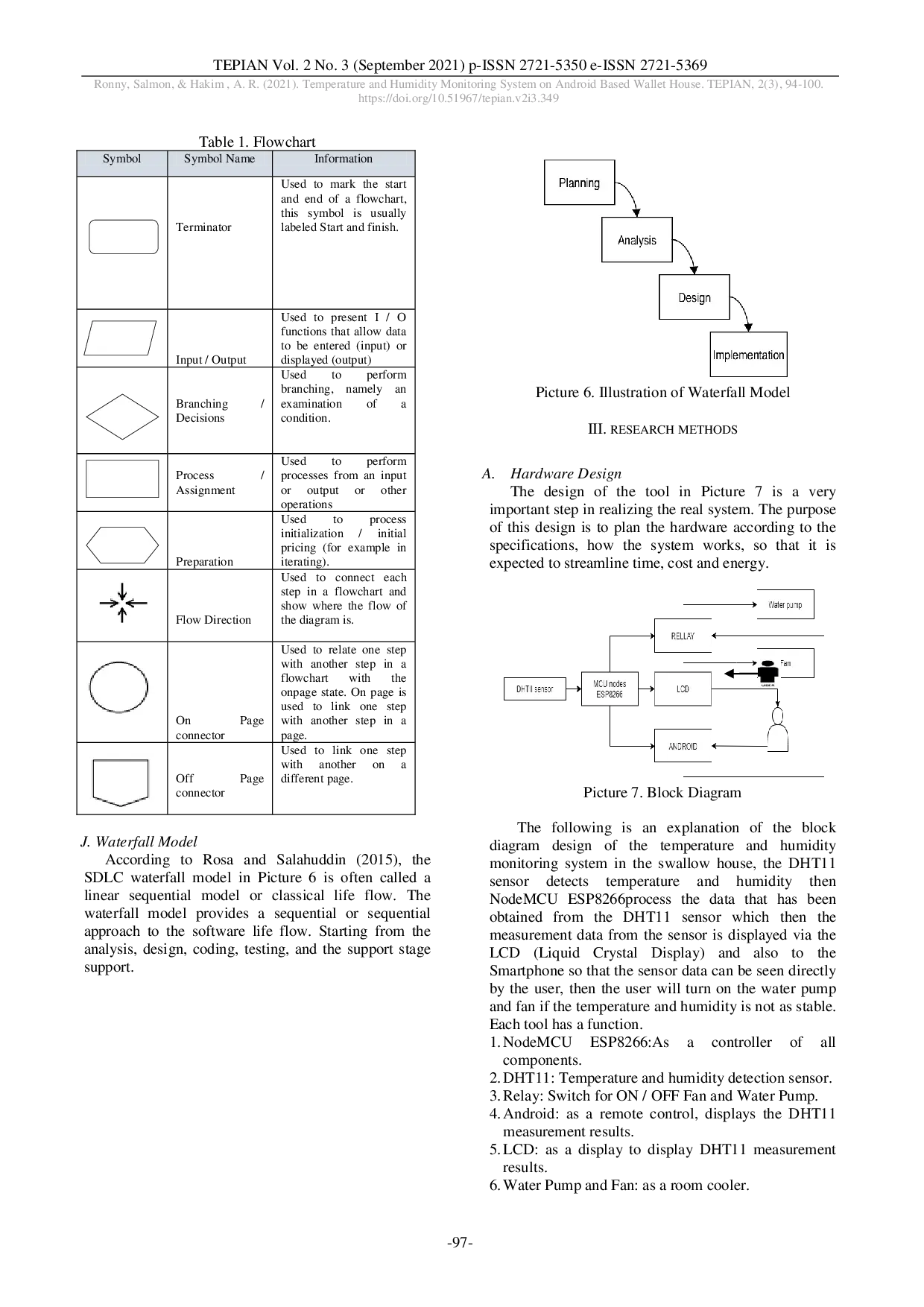

POLITANI SAMARINDAPOLITANI SAMARINDA Suhu dan kelembaban merupakan hal penting dalam laboratorium kimia. Dengan memanfaatkan internet, operator dapat memantau suhu dan kelembaban laboratoriumSuhu dan kelembaban merupakan hal penting dalam laboratorium kimia. Dengan memanfaatkan internet, operator dapat memantau suhu dan kelembaban laboratorium

POLITANI SAMARINDAPOLITANI SAMARINDA Perangkat lunak penunjang meliputi Arduino Integrated Development Environment dan Blynk. Sistem monitoring suhu dan kelembaban di rumah burung kolibriPerangkat lunak penunjang meliputi Arduino Integrated Development Environment dan Blynk. Sistem monitoring suhu dan kelembaban di rumah burung kolibri

POLITANI SAMARINDAPOLITANI SAMARINDA Analisis desain sistem menggunakan UML (Unified Modeling Language) yang terdiri dari Diagram Use Case, Diagram Aktivitas, dan Diagram Urutan. Dalam pengembanganAnalisis desain sistem menggunakan UML (Unified Modeling Language) yang terdiri dari Diagram Use Case, Diagram Aktivitas, dan Diagram Urutan. Dalam pengembangan

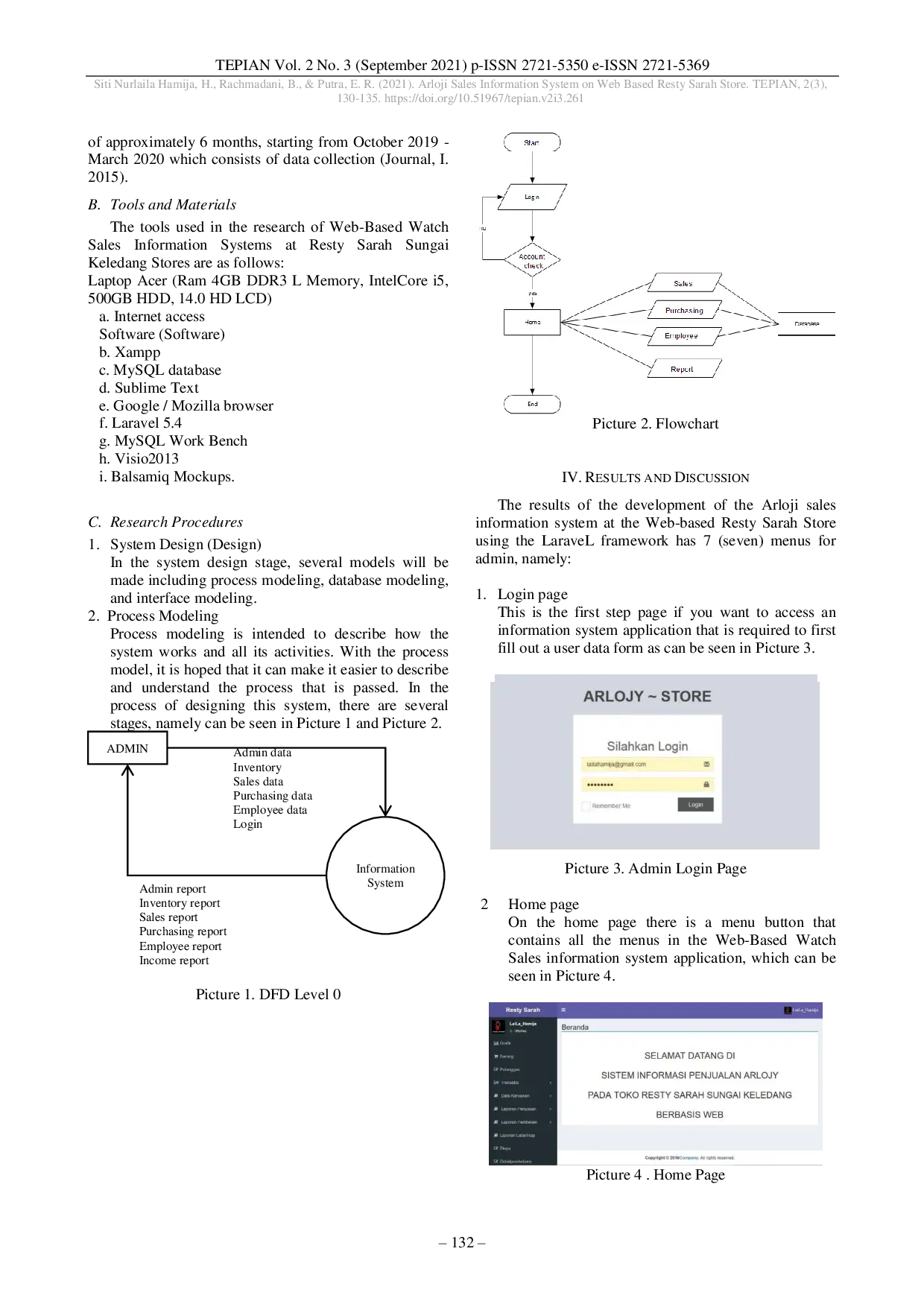

POLITANI SAMARINDAPOLITANI SAMARINDA Sistem informasi ini dapat mengatasi kesalahan dalam perhitungan penjualan dan transaksi pembelian, serta memudahkan pengumpulan data jenis barang di TokoSistem informasi ini dapat mengatasi kesalahan dalam perhitungan penjualan dan transaksi pembelian, serta memudahkan pengumpulan data jenis barang di Toko

TAHTAMEDIATAHTAMEDIA Pengabdian ini berfokus pada pelatihan kader untuk mengidentifikasi depressi dan memberikan penatalaksanaan efektif kepada lansia dengan penyakit TBC.Pengabdian ini berfokus pada pelatihan kader untuk mengidentifikasi depressi dan memberikan penatalaksanaan efektif kepada lansia dengan penyakit TBC.

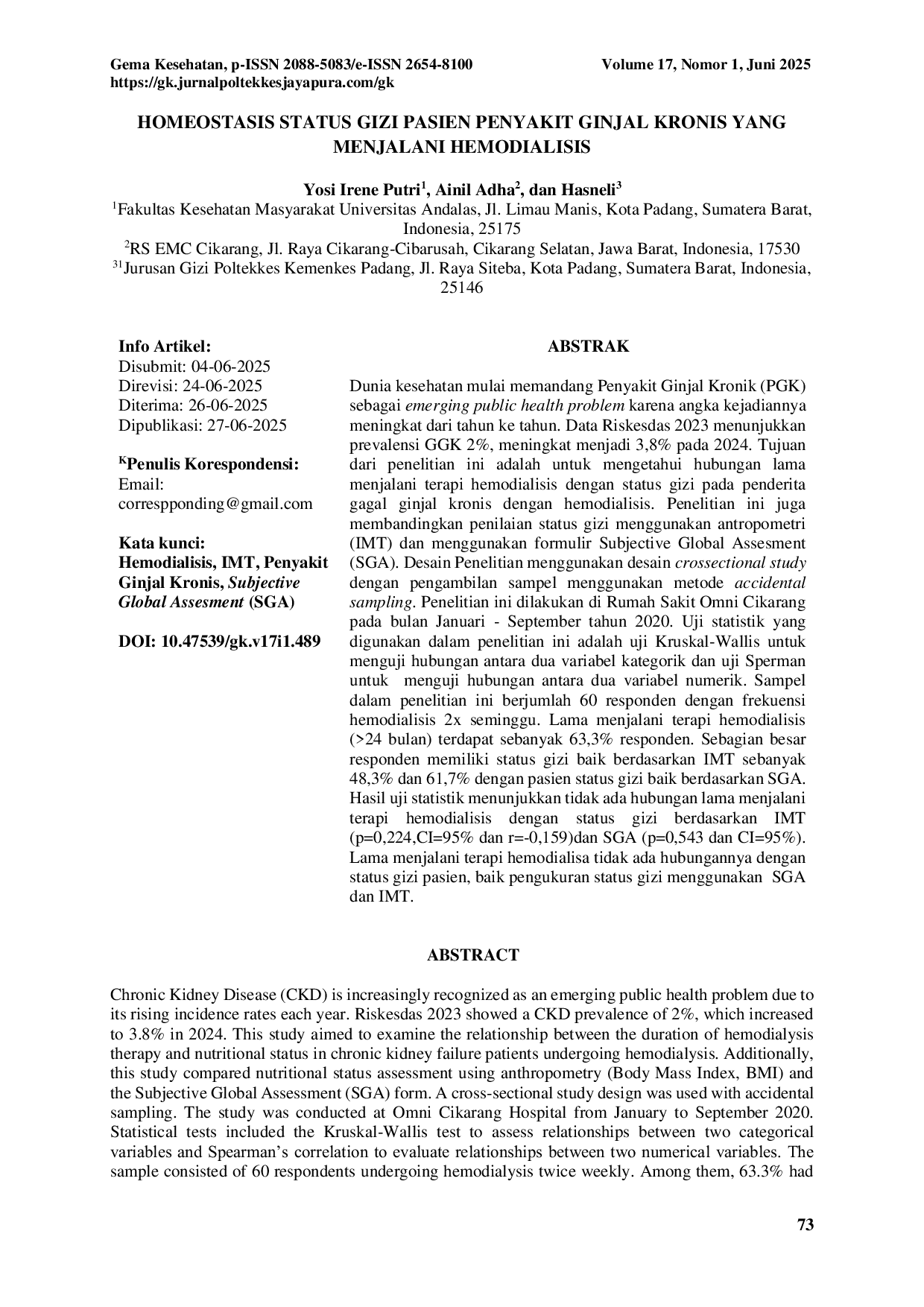

Useful /

POLTEKKES JAYAPURAPOLTEKKES JAYAPURA Sampel dalam penelitian ini berjumlah 60 responden dengan frekuensi hemodialisis 2x seminggu. Lama menjalani terapi hemodialisis (>24 bulan) terdapat sebanyakSampel dalam penelitian ini berjumlah 60 responden dengan frekuensi hemodialisis 2x seminggu. Lama menjalani terapi hemodialisis (>24 bulan) terdapat sebanyak

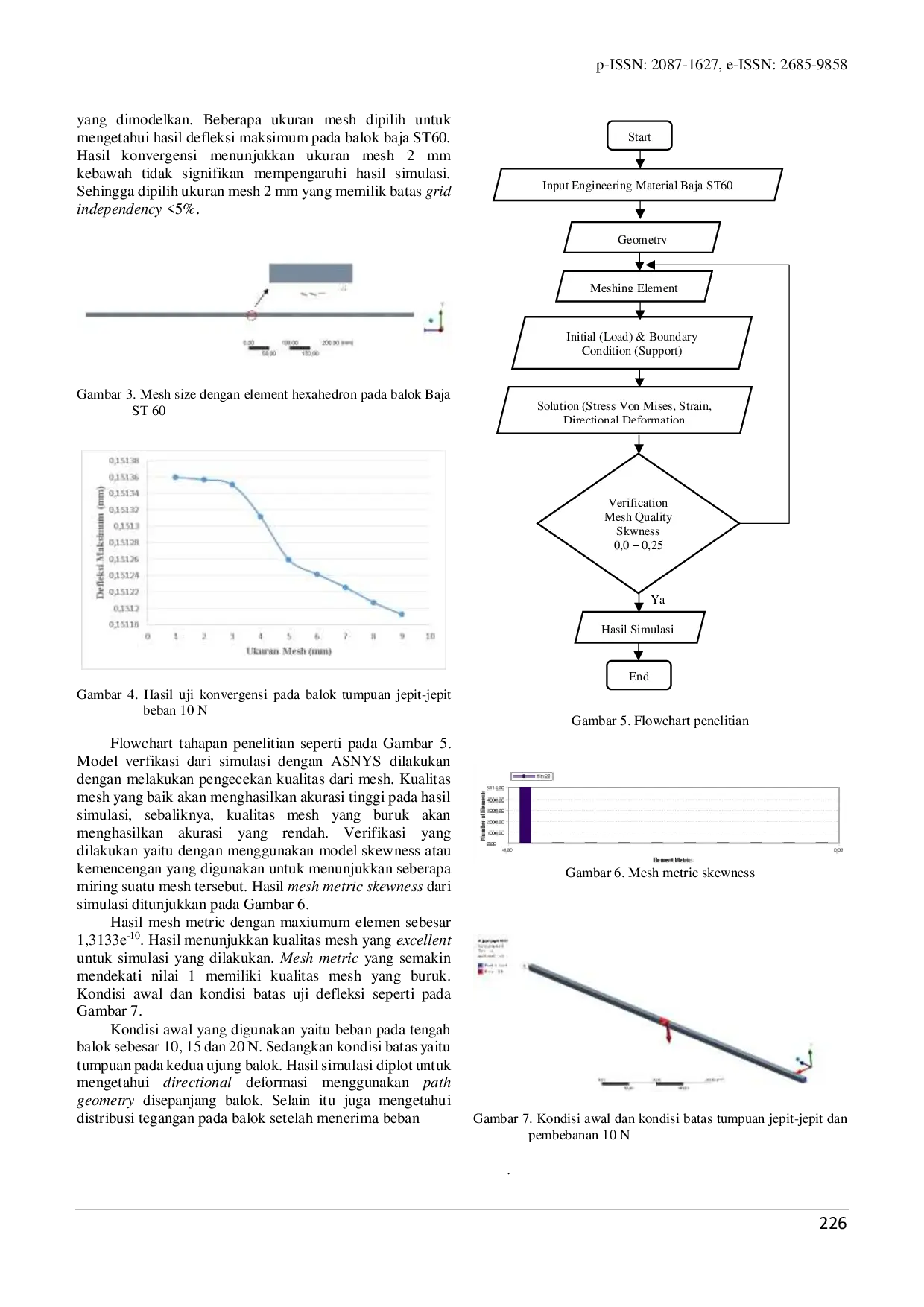

PNCPNC Hasil simulasi numerik menunjukkan bahwa defleksi pada balok baja ST 60 meningkat seiring dengan peningkatan beban, dengan tumpuan engsel-rol menghasilkanHasil simulasi numerik menunjukkan bahwa defleksi pada balok baja ST 60 meningkat seiring dengan peningkatan beban, dengan tumpuan engsel-rol menghasilkan

POLTEKKES JAYAPURAPOLTEKKES JAYAPURA Ibu yang memiliki balita underweight sebaiknya lebih memperhatikan pola konsumsi, terutama frekuensi makanan.menu yang dihidangkan harus lebih bervariasiIbu yang memiliki balita underweight sebaiknya lebih memperhatikan pola konsumsi, terutama frekuensi makanan.menu yang dihidangkan harus lebih bervariasi

POLTEKKES JAYAPURAPOLTEKKES JAYAPURA Ekstrak kemangi selanjutnya dilakukan uji fitokimia untuk mengetahui kandungan senyawa metabolit sekunder. Hasil dari penelitian ini menunjukkan bahwaEkstrak kemangi selanjutnya dilakukan uji fitokimia untuk mengetahui kandungan senyawa metabolit sekunder. Hasil dari penelitian ini menunjukkan bahwa