IAESCOREIAESCORE

International Journal of Electrical and Computer Engineering (IJECE)International Journal of Electrical and Computer Engineering (IJECE)Extrusion is one of the important processes to manufacture and produce military and industrial components. Designing its tools is usually associated with trial and error and needs great expertise and adequate experience. Reverse extrusion process is known as one of the common processes for production of hollow parts with closed ends. The significant load required in formation of a workpiece is one of the existing constraints for the reverse extrusion process. This issue becomes rather difficult especially for the parts having thin walls since its analysis using finite element softwares is exposed to some limitations. In this regard, application of artificial intelligence for prediction of load in the reverse extrusion process will not only save time and money, but also improve quality features of the product. Based on the existing data and methods suggested for variations of punching force through the reverse extrusion process, the system is trained and then performance of the system is evaluated using the test data in this paper. Efficiency of the proposed method is also assessed via comparison with the results of others.

Reverse extrusion is a common process for manufacturing hollow parts with closed ends and thus has numerous applications in different industries.The significant load required for forming the workpiece is one of the main drawbacks of the reverse extrusion process.A load prediction system is developed in this research based on the information gathered from reverse extrusion forge analysis and artificial intelligence algorithms.These results may properly contribute to improve the reverse extrusion process considering accuracy of each of them in the test phase.

Penelitian lebih lanjut dapat dilakukan untuk mengeksplorasi penggunaan algoritma kecerdasan buatan yang lebih canggih, seperti jaringan saraf tiruan dalam (deep neural networks), untuk meningkatkan akurasi prediksi beban dalam proses ekstrusi balik. Selain itu, studi komprehensif mengenai pengaruh parameter proses, seperti kecepatan ekstrusi dan suhu, terhadap akurasi prediksi beban perlu dilakukan. Terakhir, pengembangan model prediktif yang mampu memperhitungkan variasi material dan geometri benda kerja secara dinamis akan sangat bermanfaat untuk mengoptimalkan desain alat dan proses ekstrusi balik, sehingga menghasilkan produk dengan kualitas yang lebih baik dan biaya yang lebih efisien. Penelitian-penelitian ini diharapkan dapat memberikan kontribusi signifikan dalam meningkatkan efisiensi dan efektivitas proses manufaktur ekstrusi balik.

| File size | 480.33 KB |

| Pages | 6 |

| DMCA | ReportReport |

Related /

POLIMEDIAPOLIMEDIA Anggota UMKM Koperasi Wanita Atsiri mampu meningkatkan pemasaran dan promosi produk menggunakan Platform Media Sosial dan Internet. Dengan memberikan penyuluhanAnggota UMKM Koperasi Wanita Atsiri mampu meningkatkan pemasaran dan promosi produk menggunakan Platform Media Sosial dan Internet. Dengan memberikan penyuluhan

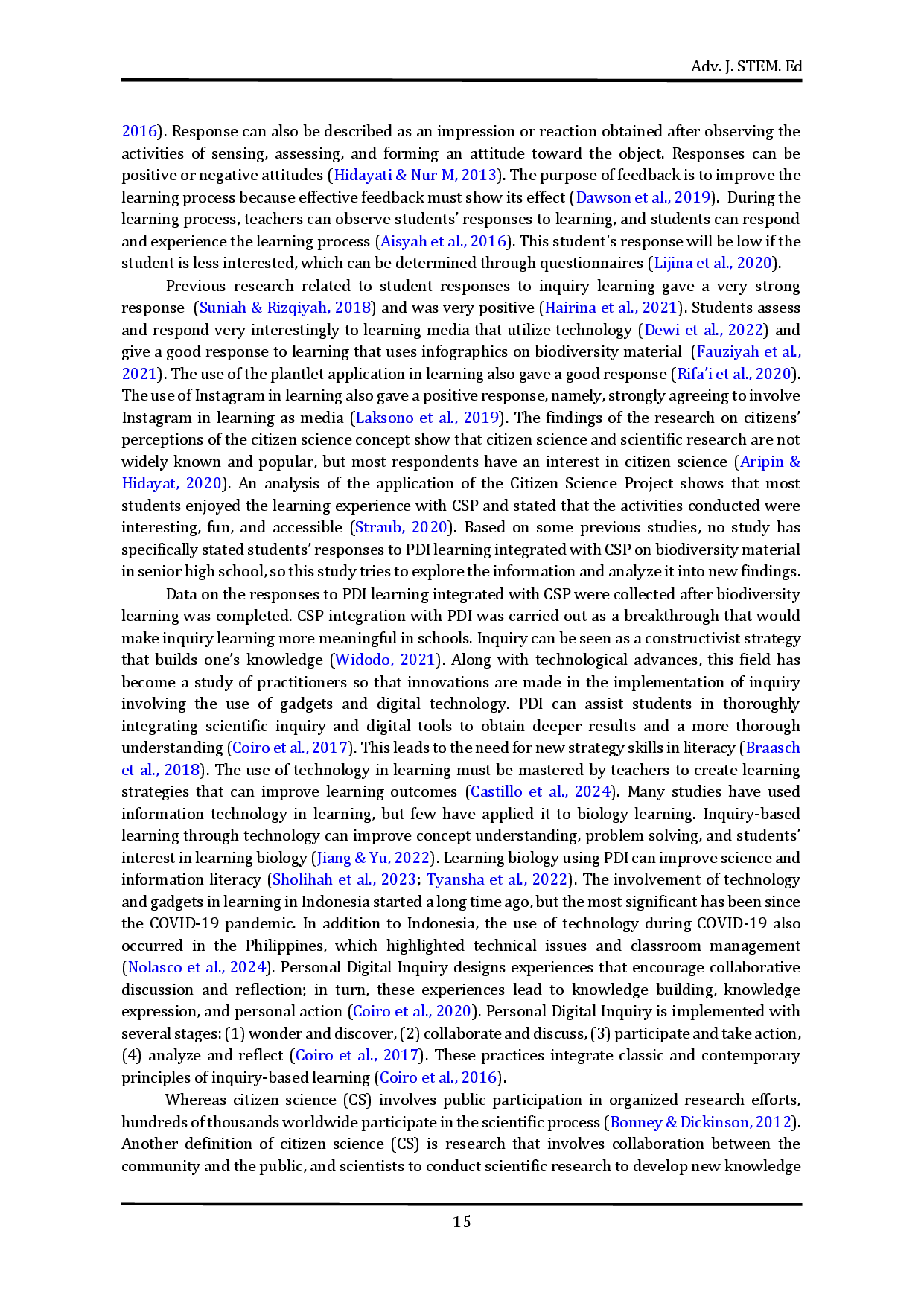

RESEARCHSYNERGYPRESSRESEARCHSYNERGYPRESS Selain itu, perlu dikaji apakah model ini dapat diterapkan pada materi biologi lain seperti ekosistem atau konservasi satwa liar, dan bagaimana modifikasiSelain itu, perlu dikaji apakah model ini dapat diterapkan pada materi biologi lain seperti ekosistem atau konservasi satwa liar, dan bagaimana modifikasi

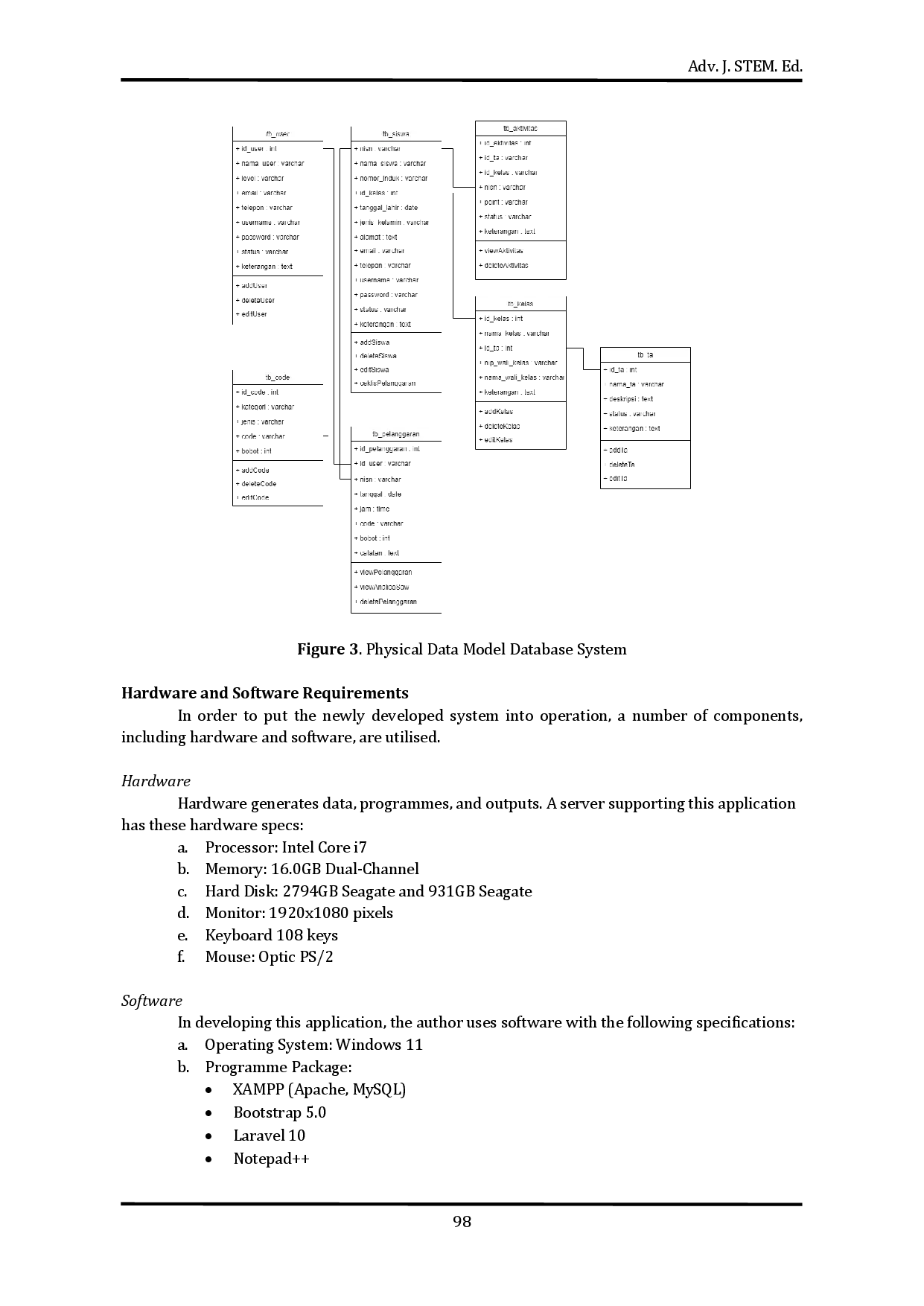

RESEARCHSYNERGYPRESSRESEARCHSYNERGYPRESS Penelitian ini mengembangkan sistem pendukung keputusan berbasis web menggunakan metode Simple Additive Weighting (SAW) untuk secara objektif menilai danPenelitian ini mengembangkan sistem pendukung keputusan berbasis web menggunakan metode Simple Additive Weighting (SAW) untuk secara objektif menilai dan

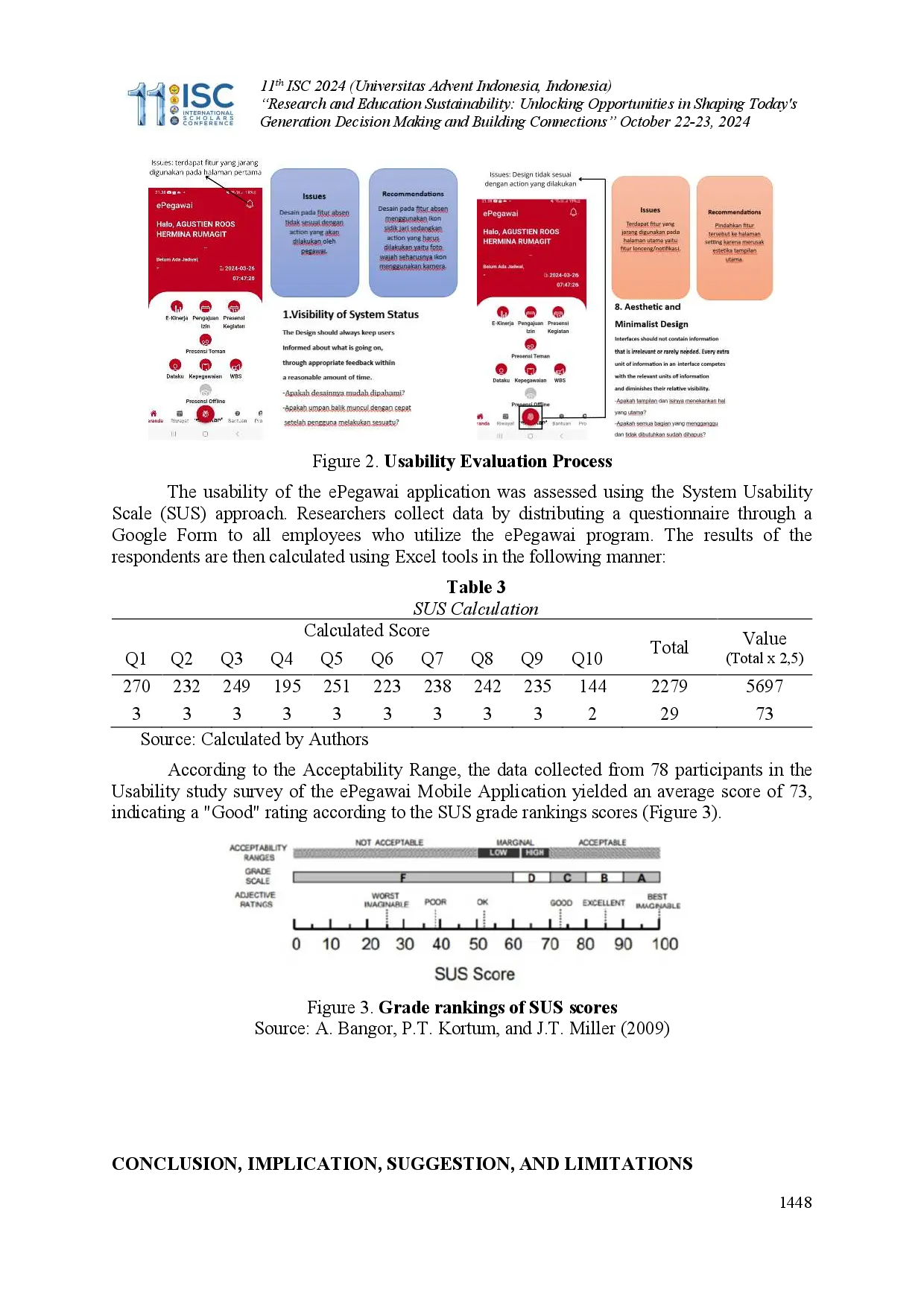

UNAIUNAI The research findings indicate that this study intends to ascertain the perspectives of employees regarding the interface design of the mobile attendanceThe research findings indicate that this study intends to ascertain the perspectives of employees regarding the interface design of the mobile attendance

Useful /

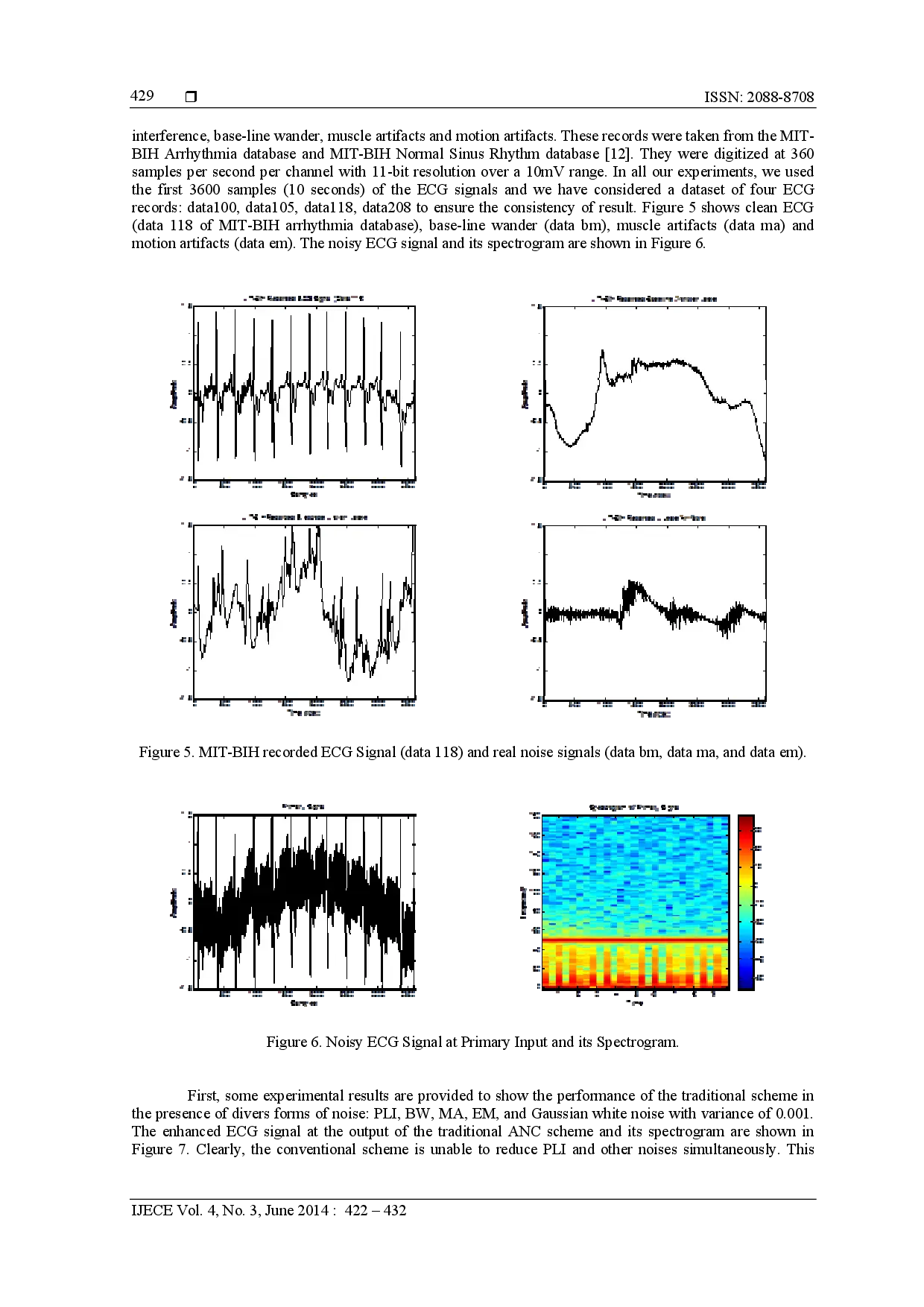

IAESCOREIAESCORE Ponsel cerdas semakin diterima sebagai alat yang efektif untuk pemantauan kesehatan jarak jauh. Selama perekaman elektrokardiografik (ECG), kehadiran berbagaiPonsel cerdas semakin diterima sebagai alat yang efektif untuk pemantauan kesehatan jarak jauh. Selama perekaman elektrokardiografik (ECG), kehadiran berbagai

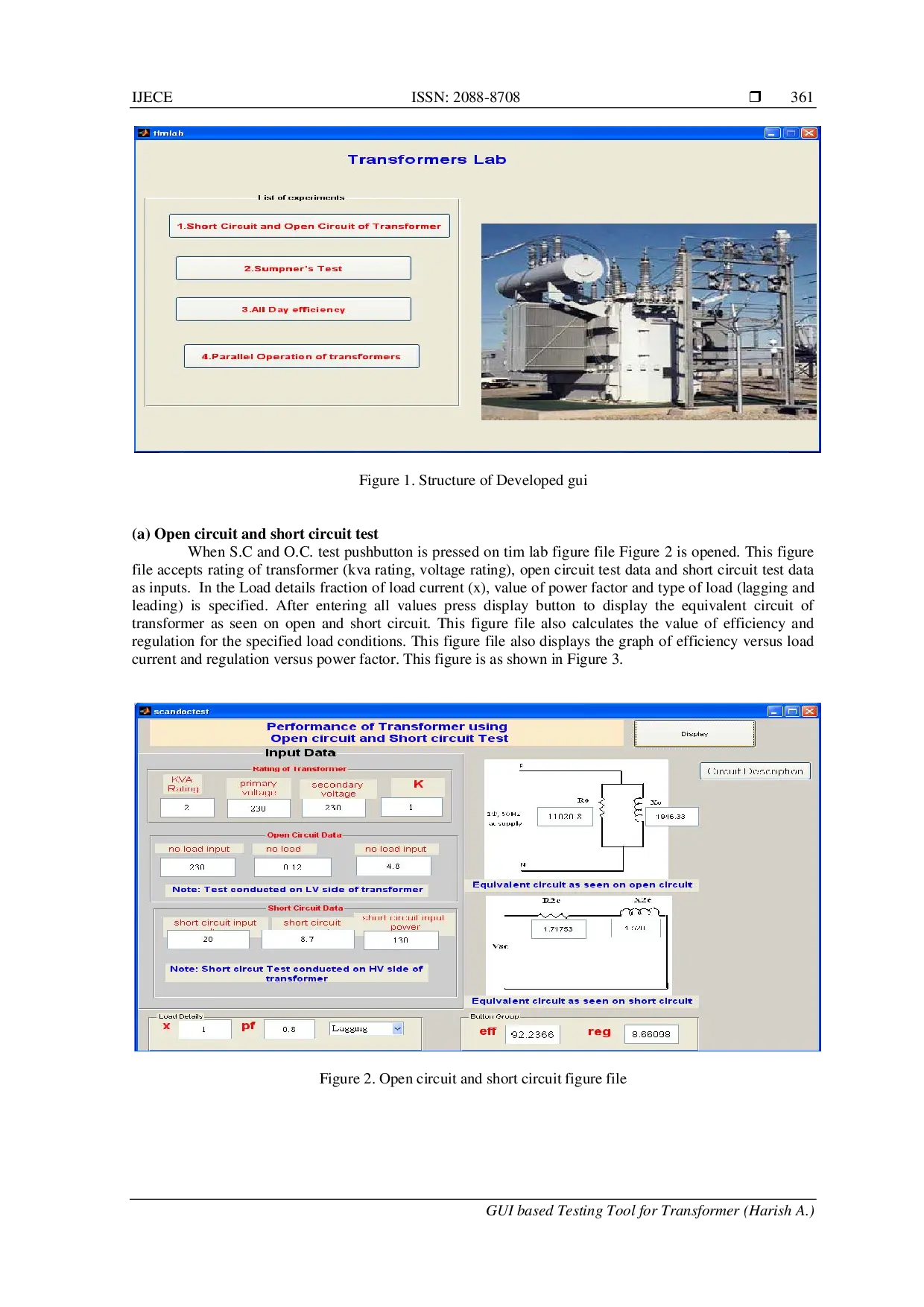

IAESCOREIAESCORE File figur GUI dikembangkan untuk Uji Sirkuit Terbuka & Sirkuit Pendek, Uji Sumpner, efisiensi sepanjang hari (efisiensi energi) transformator, dan operasiFile figur GUI dikembangkan untuk Uji Sirkuit Terbuka & Sirkuit Pendek, Uji Sumpner, efisiensi sepanjang hari (efisiensi energi) transformator, dan operasi

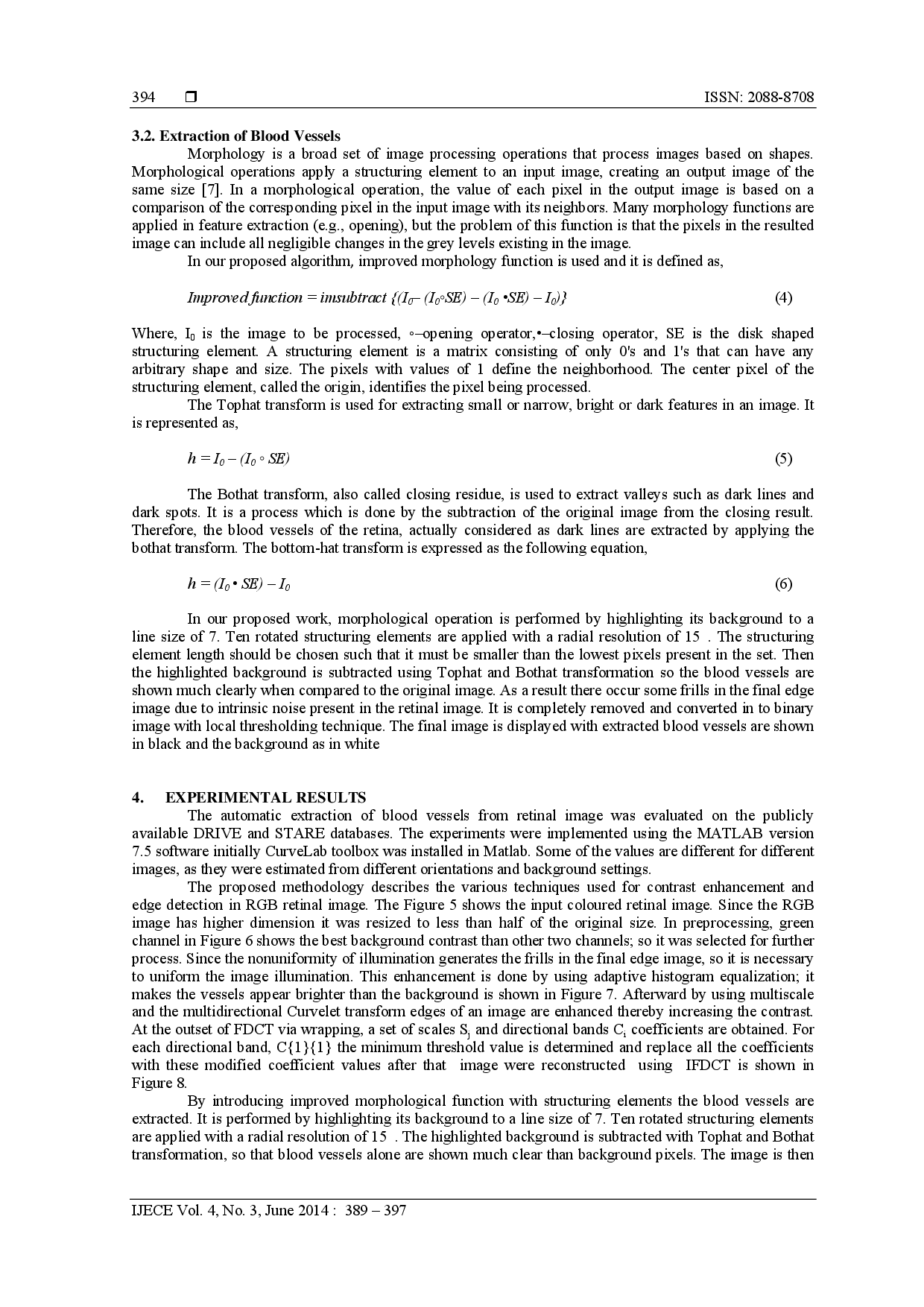

IAESCOREIAESCORE Metode yang diusulkan berhasil menggabungkan adaptive histogram equalization, transformasi Curvelet, dan fungsi morfologi Bothat serta Tophat yang diikutiMetode yang diusulkan berhasil menggabungkan adaptive histogram equalization, transformasi Curvelet, dan fungsi morfologi Bothat serta Tophat yang diikuti

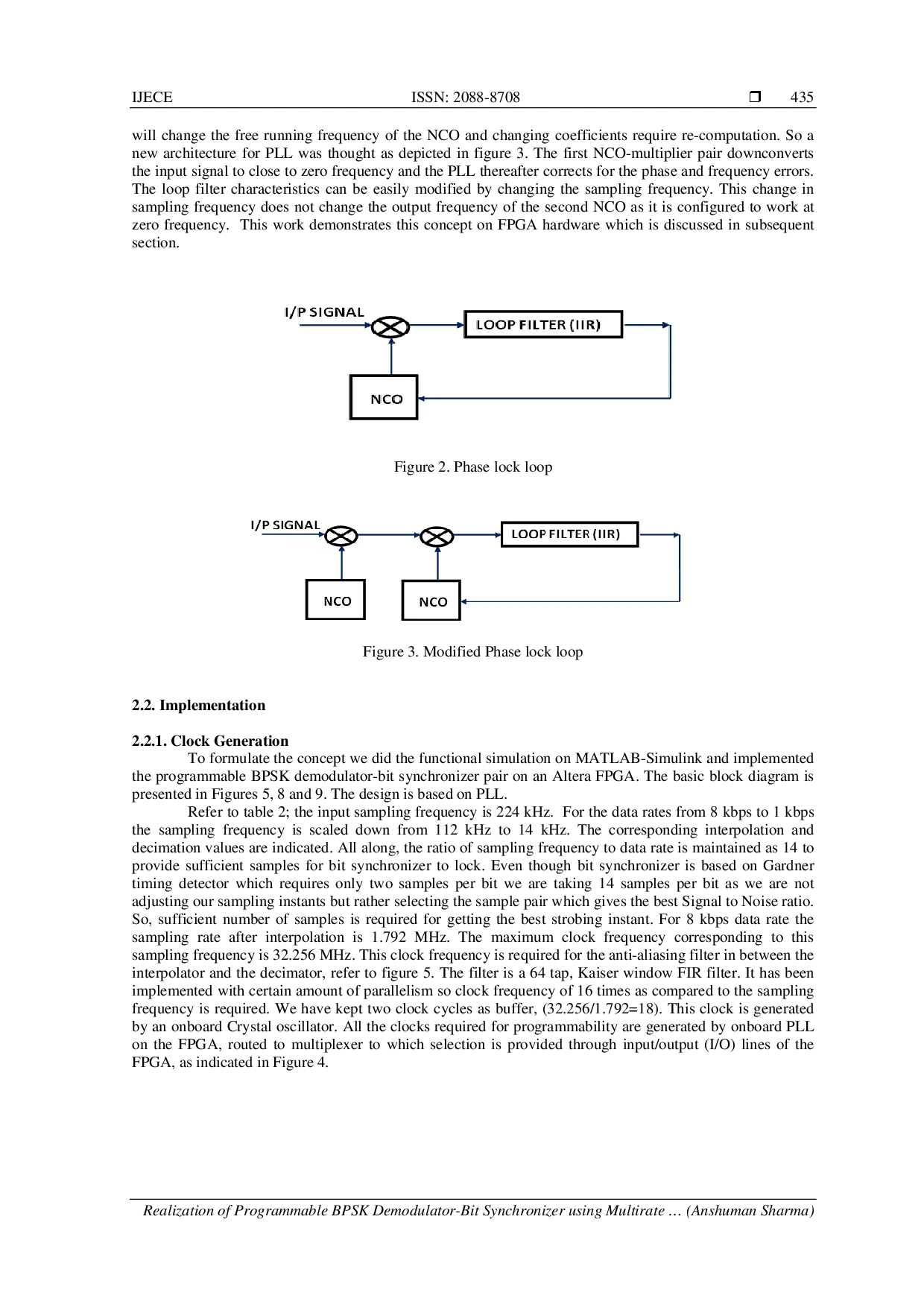

IAESCOREIAESCORE Penelitian ini juga menunjukkan bahwa kebutuhan clock yang lebih tinggi dapat dioptimalkan lebih lanjut dengan mengimplementasikan filter FIR dengan paralelismePenelitian ini juga menunjukkan bahwa kebutuhan clock yang lebih tinggi dapat dioptimalkan lebih lanjut dengan mengimplementasikan filter FIR dengan paralelisme