URECOLURECOL

Urecol Journal. Part D: Applied SciencesUrecol Journal. Part D: Applied SciencesThe current industrial implementation process is required to be carried out efficiently and environmentally friendly, this can be done with the presence of a heat exchanger. However, heat exchangers in the production of aluminum nitride nanoparticles are still rare. The purpose of this research is to analyze and improve the heat exchanger design in the production process of aluminum nitride nanoparticles at low cost. The heat exchanger can be designed based on several parameters of the TEMA standard by dimensional specification and specifications of hot and cold fluids. The method is calculated using a Microsoft excel application to evaluate the heat exchanger design according to the TEMA standard. The results showed that the shell and tube heat exchanger was designed with 39 tubes and an effective value of 85.72%. These results have met the TEMA standard and it is hoped that the design and evaluation of this heat exchanger can be used as a reference in the aluminum nitride nanoparticle production industry.

Based on the calculations and analysis conducted, the design of a shell and tube heat exchanger for the production of aluminum nitride nanoparticles, adhering to TEMA standards, has been successfully developed.The designed heat exchanger features 39 tubes and demonstrates an effectiveness of over 85%, indicating good performance.This design is expected to contribute to cost-effective production and environmentally friendly practices within the aluminum nitride nanoparticle industry.

Penelitian lebih lanjut dapat dilakukan untuk menguji kinerja heat exchanger yang dirancang dalam skala industri yang sebenarnya, mempertimbangkan variabel operasional yang lebih kompleks seperti fluktuasi aliran dan tekanan. Selain itu, studi komparatif dapat dilakukan dengan berbagai konfigurasi heat exchanger, seperti plate heat exchanger atau spiral heat exchanger, untuk mengidentifikasi desain yang paling optimal untuk produksi aluminium nitrida. Terakhir, penelitian dapat difokuskan pada penggunaan nanofluida sebagai fluida kerja untuk meningkatkan efisiensi perpindahan panas dan mengurangi konsumsi energi dalam proses produksi aluminium nitrida, dengan mempertimbangkan potensi dampak lingkungan dan biaya yang terkait.

| File size | 485.52 KB |

| Pages | 9 |

| DMCA | Report |

Related /

ASSYIFAASSYIFA Fokus utama adalah mengidentifikasi jenis-jenis kesalahan yang paling sering terjadi, faktor-faktor penyebabnya, serta implikasinya bagi pengajaran bahasaFokus utama adalah mengidentifikasi jenis-jenis kesalahan yang paling sering terjadi, faktor-faktor penyebabnya, serta implikasinya bagi pengajaran bahasa

POLTEKKES MKSPOLTEKKES MKS Pengambilan sampel dilakukan dengan metode Non Probability sampling dengan cara Purposive Random Sampling. Penelitian ini dilaksanakan pada bulan MaretPengambilan sampel dilakukan dengan metode Non Probability sampling dengan cara Purposive Random Sampling. Penelitian ini dilaksanakan pada bulan Maret

POLTEKKES MKSPOLTEKKES MKS Anemia merupakan masalah gizi yang paling sering terjadi dan dapat terjadi pada kelompok usia muda. Pola makan yang tidak seimbang merupakan salah satuAnemia merupakan masalah gizi yang paling sering terjadi dan dapat terjadi pada kelompok usia muda. Pola makan yang tidak seimbang merupakan salah satu

POLTEKKES MKSPOLTEKKES MKS Metode: Tujuan penelitian ini adalah untuk mengetahui perbandingan pengaruh Mobilisasi saraf dan Spinal Mobilization With Leg Movement (SMWLM) terhadapMetode: Tujuan penelitian ini adalah untuk mengetahui perbandingan pengaruh Mobilisasi saraf dan Spinal Mobilization With Leg Movement (SMWLM) terhadap

POLTEKKES MKSPOLTEKKES MKS E program pada bayi pasca resusitasi selama proses rujukan guna mencegah meningkatnya angka kesakitan dan timbulnya jejas (sequele) akibat asfiksia bayiE program pada bayi pasca resusitasi selama proses rujukan guna mencegah meningkatnya angka kesakitan dan timbulnya jejas (sequele) akibat asfiksia bayi

POLTEKKES MKSPOLTEKKES MKS Data dari Ketua Rukun Tetangga (RT) menunjukkan sejak awal pandemi hingga Juli 2021 terdapat 15 kasus COVID-19 yang terjadi pada masyarakat di perumahanData dari Ketua Rukun Tetangga (RT) menunjukkan sejak awal pandemi hingga Juli 2021 terdapat 15 kasus COVID-19 yang terjadi pada masyarakat di perumahan

POLTEKKES MKSPOLTEKKES MKS Tujuan. Penelitian ini bertujuan untuk mengetahui hubungan frekuensi penggunaan media sosial dengan kebiasaan mengonsumsi fast food pada remaja di KotaTujuan. Penelitian ini bertujuan untuk mengetahui hubungan frekuensi penggunaan media sosial dengan kebiasaan mengonsumsi fast food pada remaja di Kota

UNTAG SMDUNTAG SMD Tujuan penelitian ini adalah untuk menentukan perhitungan biaya produksi rumah tipe 75 di PT. Alif Persada Nusantara (Garden Hills Samarinda Housing) yangTujuan penelitian ini adalah untuk menentukan perhitungan biaya produksi rumah tipe 75 di PT. Alif Persada Nusantara (Garden Hills Samarinda Housing) yang

Useful /

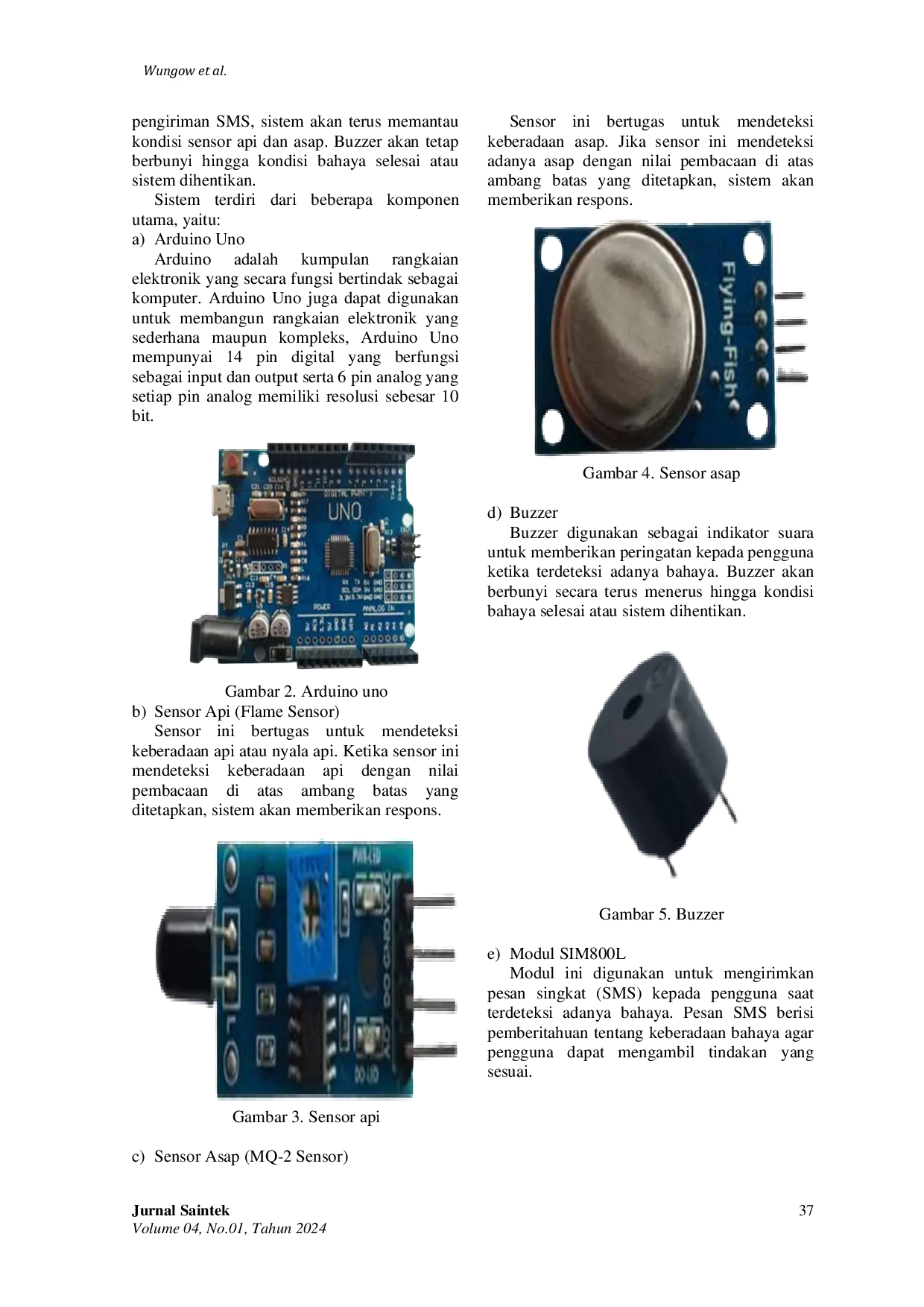

UNSRITUNSRIT Berdasarkan hasil penelitian, dapat disimpulkan bahwa alat deteksi kebakaran berbasis Arduino ini berfungsi dengan baik sesuai dengan fungsionalitas yangBerdasarkan hasil penelitian, dapat disimpulkan bahwa alat deteksi kebakaran berbasis Arduino ini berfungsi dengan baik sesuai dengan fungsionalitas yang

POLTEKKES MKSPOLTEKKES MKS Pneumonia pada balita masih menjadi masalah kesehatan utama di Indonesia, ditandai dengan tingginya angka morbiditas dan mortalitas. Penelitian ini bertujuanPneumonia pada balita masih menjadi masalah kesehatan utama di Indonesia, ditandai dengan tingginya angka morbiditas dan mortalitas. Penelitian ini bertujuan

POLTEKKES MKSPOLTEKKES MKS Bagian morfologi daun dan biji merupakan bagian yang paling banyak digunakan. Skrining fitokimia terhadap tanaman ini menunjukkan adanya senyawa metabolitBagian morfologi daun dan biji merupakan bagian yang paling banyak digunakan. Skrining fitokimia terhadap tanaman ini menunjukkan adanya senyawa metabolit

UNTAG SMDUNTAG SMD Dapat meningkatkan jumlah wajib pajak orang pribadi dan penerimaan pajak untuk tahun 2015-2019 di Kantor Pelayanan Pajak Pratama Samarinda di Samarinda.Dapat meningkatkan jumlah wajib pajak orang pribadi dan penerimaan pajak untuk tahun 2015-2019 di Kantor Pelayanan Pajak Pratama Samarinda di Samarinda.